01 Characterization of the toughness of plastics

Toughness, as opposed to rigidity, is a quality that represents how challenging it is to deform an item. The likelihood of deformation decreases with increasing rigidity, but deformation is made simpler with increased toughness. In general, a material's rigidity determines its hardness, tensile strength, Young's modulus, flexural strength, and flexural modulus; conversely, a material's toughness determines its elongation at break and impact strength. big. Impact strength is the ability of a spline or workpiece to survive an impact; it often refers to the amount of energy that the spline can take before breaking.

Impact strength cannot be categorized as a fundamental attribute of the material since it varies based on the spline's form, the testing procedure, and the state of the test sample.

Impact tests can be done in a variety of ways. There are three different types of impact tests depending on the test temperature: normal temperature impact, low temperature impact, and high temperature impact. Additionally, depending on the sample's stress state, there are four different types of impact tests: bending impact (including cantilever beam and charpy impacts), tensile impact, torsional impact, and shear impact. Cutting impact may be split into two categories: single impacts with high energy and many impacts with low energy, depending on how many impacts are made. Different impact test techniques can be chosen for various materials or applications, leading to a variety of findings that cannot be compared.

02 Plastic toughening mechanism

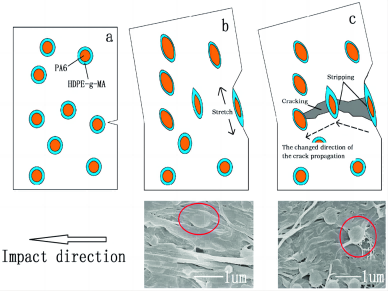

There are two types of plastic toughening: rigid toughening agent toughening and flexible toughening agent toughening. The theories of direct energy absorption by elastomers, yield, crack core, multiple craze, craze-shear band, craze branching, Wu's theory, etc. are examples of the toughening mechanism. The craze-shear band hypothesis is one of those that has gained a lot of acceptance since it can satisfactorily explain a number of experimental data.

The craze-shear band hypothesis states that rubber particles primarily play two roles in the rubber-toughened plastic mix system:

On the one hand, it causes many crazes and shear bands in the matrix as the site of concentrated stress;

On the other side, crazes can be prevented from becoming destructive fractures by limiting their ability to spread.

Shear bands may be induced by the stress field toward the conclusion of the frenzy to bring it to a halt. Additionally, it stops crazes from growing when they enter the shear zone. Energy is used during the formation and growth of many crazes and shear bands when the material is stressed, which increases the material's toughness. Shear banding is associated with the formation of narrow necks, whereas craze shows macroscopically as a stress whitening event. These two phenomena have distinct behaviors in various plastic substrates.

03 Contributing factors to the plastic toughening impact

1. Matrix resin characteristics

According to studies, increasing the matrix resin's hardness will also increase the toughening effect of toughened plastics. The following methods may be used to increase the matrix resin's toughness: managing crystallization and crystallinity, crystal size and shape, etc.; raising the matrix resin's molecular weight to narrow the molecular weight distribution. For instance, adding a nucleating agent to polypropylene (PP) speeds up crystallization and refines the grain structure, increasing the material's fracture toughness.

2. Toughening agent dose and characteristics

A. The toughening agent's dispersed phase's particle sizeThe qualities of the matrix resin and the ideal value of the particle size of the elastomer's dispersion phase are different for elastomer-toughened plastics. For instance, the ideal rubber particle size in HIPS is between 0.8 and 1.3 m, the ideal ABS particle size is around 0.3 m, and the ideal PVC-modified ABS particle size is roughly 0.1 m.

B. Toughener glass transition temperature – the toughening effect is improved when the glass transition temperature of general elastomers is lower;

C. The interfacial binding strength between the toughening agent and the matrix resin, which affects the toughening effect differently depending on the system;

D. The structure of elastomer tougheners, which depends on the kind of elastomer, the degree of crosslinking, etc.

E. The amount of toughening agent – the particle distance parameter is connected to the ideal amount of toughening agent supplied;

3. The force that binds the two phases together

The macroscopically higher overall performance of the plastic is mostly due to the gain in impact strength, but a good bonding force between the two phases can also make it possible for stress to be successfully conveyed between the phases while using more energy. This binding force is typically thought of as the interaction between two phases. Block and graft copolymerization are frequent techniques for enhancing the bonding force between two phases. The distinction is that they create chemical linkages using techniques like grafting and block copolymerization. HIPS, ABS, SBS, and PUR are examples of block copolymers.

It falls under the category of physical blending for polymers that have been hardened, but the basic idea is the same. The two components should be somewhat compatible and create their own phases in the ideal blending mechanism. Between the stages is an interface layer. The two polymers' molecular chains diffuse with one another in the interface layer, and the gradient in concentration is clear. As the mixing is intensified The components' compatibility results in a strong binding force, which subsequently improves diffusion to scatter the interface and thicken the interface layer. The crucial technology for creating polymer alloys at this point is polymer compatibility technology, which also includes plastic toughening!

04 What are the techniques for toughening plastic?

EPR (ethylene propylene diene), EPDM (ethylene propylene diene), butadiene rubber (BR), natural rubber (NR), isobutylene rubber (IBR), nitrile rubber (NBR), etc. are examples of toughened rubber elastomers. All plastic resins may be modified to become tougher using this method.

2. SBS, SEBS, POE, TPO, TPV, etc. are toughened using thermoplastic elastomers. It is mostly used to toughen polyolefins or non-polar resins; when used to toughen polymers with polar functional groups, such as polyesters and polyamides, a compatibilizer should be added.

3. Strengthening of reactive terpolymers and core-shell copolymers

ACR stands for "acrylates," MBS for "methyl acrylate-butadiene-styrene copolymer," PTW for "ethylene-butyl acrylate-glycidyl methacrylate copolymer," and so on. The majority of its applications are to toughen technical plastics and high temperature resistant polymer alloys.

4. Toughening and mixing of high-tensile plastic

PC/ABS, PC/PBT, HIPS/PPO, PP/PA, PP/ABS, PA/ABS, PPS/PA, etc. Engineering plastics with high toughness may be made in large part through the use of polymer alloy technology.

5. Additional toughening techniques

Sarin resin (a DuPont metal ionomer) toughening, nanoparticle toughening (using nano-CaCO3, for example), etc.

Free radical addition polymerization is typically used to produce general-purpose polymers. Polar groups are absent from the molecule's side chains and main chain. Engineering plastics can be toughened by adding rubber and elastomer particles for a greater toughening effect. Typically, condensation polymerization is used to create it. Polar groups are found in the side chain or terminal group of the molecular chain. It can be made tougher by using functionalized rubber or elastomer particles.

05 How to comprehend that capacity must be increased before toughening

In general, when exposed to external forces, plastics absorb and release energy via the processes of interface debonding, cavitation, and matrix shear yielding. Elastomers with high compatibility, with the exception of non-polar polymeric resins, can be applied directly. To achieve the goal of final toughening when utilizing particles (same compatibility principle), other polar resins must be successfully compatibilized. The graft copolymers indicated above will interact strongly with the matrix when utilized as tougheners, including:

(1) The addition reaction between the epoxy functional group and the polymer's terminal hydroxyl, carboxyl, or amine group takes place after the ring is opened.

(2) Core-shell toughening mechanism: the rubber has a toughening effect while the outside functional group is completely compatible with the components;

(3) Ionomer toughening mechanism: The physical crosslinking network is created when metal ions and carboxylate groups of polymer chains complex, toughening the material.

In reality, this compatibilization approach may be applied to all polymer blends if the toughener is thought of as a class of polymers. Reactive compatibilization is a method we must employ when creating practical polymer blends for industry. The term "toughening agent" now refers to a "interfacial emulsifier" or "toughening compatibilizer," respectively. The name is quite expressive!