Modified plastics are an important part of the new chemical materials sector, with application markets including home appliances, automobiles, electronic appliances, office equipment, construction materials, rail transportation, aerospace and other areas of national importance and livelihood. The rate of plastic modification is one of the most important indicators of the level of development of plastic materials in a country.

In 2021, the output of primary forms of plastics in China reaches 92.4 million tons, and the output of modified plastics above the scale reaches 21.93 million tons, with a modification rate of 23.73%, but compared with the modification rate of nearly 50% in developed countries, the room for improvement is high. 2018 to 2020, China’s modified plastics market size from 225 billion yuan to 293.5 billion yuan, with a compound annual growth rate of 14.21%.

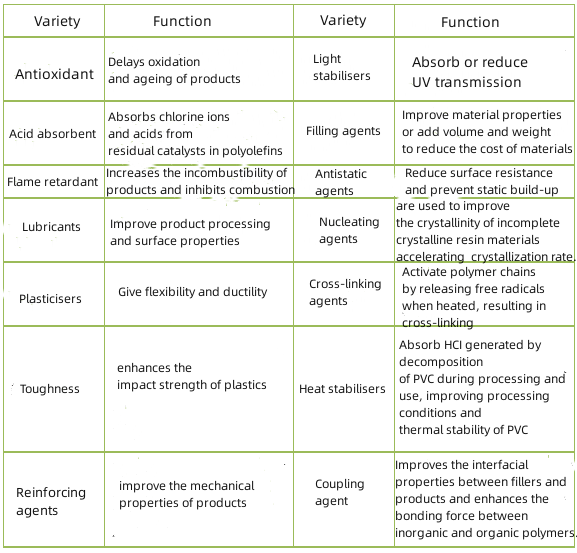

As an important auxiliary material for plastic modification, the plastic additives industry is also developing rapidly, and the compound annual growth rate (CAGR) of plastic additives is expected to be 5.71% from 2022-2027. Plastic additives, also known as plastic additives, are compounds that must be added to polymers (synthetic resins) to improve their processing properties or to improve the performance of the resin itself when they are being moulded and processed.

For example, most polymer resins, such as commonly used PP, PA, ABS, PBT, etc., are flammable fire, in some special applications must be added to flame retardant modified; in order to reduce the molding temperature of PVC, so that the products are soft and add plasticizers; and for the preparation of light quality, vibration resistance, heat insulation, sound insulation foam and to add foam; some plastic thermal decomposition temperature and Forming processing temperature is very close, without adding heat stabilizers can not be formed, but also some plastics must be added to toughening agents, weathering agents, heat agents, nucleating agents, wear agents, coloring agents, fillers, etc. to meet the application needs …….

Plastic additives as a general-purpose plastics engineering, engineering plastics, high-performance indispensable components and synthetic resin modification to achieve the key to functionalization, in the plastics processing and modification industry occupies a particularly important position.

The main polymer material additives species and the corresponding role

As competition in the plastics modification industry intensifies, innovative additives have become an important source of technological innovation and product differentiation for modified plastics.

At the same time, the plastic additives industry involves a variety of processes such as polymerization, compounding and surface treatment, and has also become a new materials industry with high technical barriers to innovation.