The fish are getting stronger in the super cold?

Nylon is weaker?

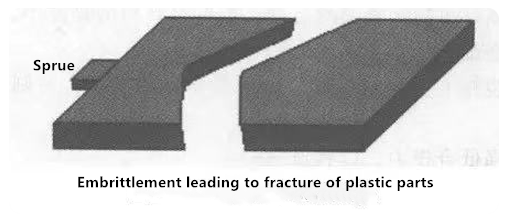

Nylon virgin resins are difficult to maintain good performance under super-low temperature working conditions, and brittle fracture at super-low temperatures has become the norm ……

The above information is obtained from a search on Baidu. Nylon 6 is resistant to low temperatures between -20 and -40°C, but when it reaches -50°C, the nylon parts will not meet the requirements of use and will produce brittle fractures.

Low temperatures, a pain point for nylon itself

At present, the most common way is to add modified additives.

A large amount of data shows that POE-g-MAH, an ethylene-octene copolymer grafted with maleic anhydride, has good performance in the low temperature toughening of nylon.

The addition of POE-g-MAH

-No fear of the cold at 50°C

Coace W1B

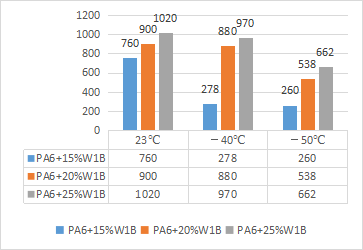

W1B is a maleic anhydride functionalised ethylene-based elastomer with an extremely low glass transition temperature, making it particularly suitable for ultra-low temperature toughening of nylon at -50°C.

Cold resistance of W1B in nylon 6

Cantilever beam notched impact strength J/m

Recommended dosage

5-25%, can be increased or decreased according to toughness requirements, taking into account the cost. PA6, PA66 reinforced toughening (2-10%), nylon and polypropylene, polyethylene co-mingled gold compatibilizer (3-10%).

Coace W1B

-The first choice for toughening nylon at 50°C