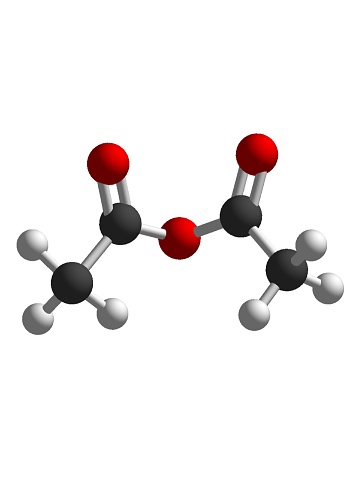

POE-g-MAH (POE grafted maleic anhydride) is obtained by grafting highly reactive maleic anhydride (MAH) monomer with POE elastomer as the base through reactive extrusion.

POE is a random copolymer elastomer of ethylene and high-carbon α-olefins (1-butene, 1-hexene, 1-octene, etc.) catalyzed by metallocene catalysts. It has excellent mechanical properties, rheological properties and UV resistance. In addition, POE also has the advantages of good affinity with polyolefins and good low-temperature toughness, and is widely used in the toughening modification of non-polar polymers such as polypropylene (PP) and polyethylene (PE).

POE is a non-polar elastomer with poor compatibility with polar materials, which is not conducive to the modification and enhancement of polar polymers such as polyamide (PA) and polyethylene terephthalate (PET). A common practice is to graft and modify POE first, and graft low-molecular-weight compounds containing polar functional groups to macromolecules, thereby changing the polarity of the POE molecular chain and improving its compatibility with polar polymers. , so that it can be applied to the modification of polar polymers. Commonly used grafting monomers for POE include maleic anhydride (MAH), glycidyl methacrylate (GMA), methacrylic acid (MAA), acrylic acid (AA), etc.

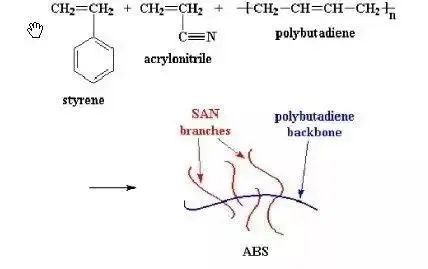

POE-g-MAH (POE grafted maleic anhydride) is obtained by grafting highly reactive maleic anhydride (MAH) monomer with POE elastomer as the base through reactive extrusion. POE-g-MAH can be used as a good toughening agent and compatibilizer, and its toughening effect is better than that of pure POE without grafting. It is suitable for PA, PP, PE, PC, ABS, PET, PBT, etc. Compatibility and toughening of its alloy materials.

POE is a thermoplastic elastomer with excellent properties. In order to broaden its application field, the graft modification of POE is the focus of research in recent years. Among them, POE-g-MAH is one of the most widely used grafts. The market prospect is broad, attracting more and more enterprises to enter the field, and promoting the continuous increase of industry production capacity. According to the “2022-2026 China POE-g-MAH Industry Market Monitoring and Future Development Prospect Research Report” released by Xinsijie Industry Research Center, in 2020, the production capacity of China’s POE-g-MAH industry will reach 41,500 tons.

A researcher from Xinsijie said that POE-g-MAH is currently the most widely used POE graft, and has achieved remarkable results in the toughening of polymer materials. The graft has excellent performance and is widely used in automobiles, electronics, etc. Terminal industries such as electrical appliances and rail transit have broad prospects. In the future, as the market trend of “replacing wood with plastic” and “replacing steel with plastic” becomes more and more obvious, the high-performance plastics industry will develop rapidly, which will also stimulate the continuous expansion of POE-g-MAH market space, POE-g- The MAH industry will usher in good development opportunities.