Plastic blending

In actuality, the majority of polymer-polymer mixtures have a low or intermediate thermodynamic compatibility. In other words, polymer-polymer mixtures often have poor compatibility. Compatibilization is a method frequently used to achieve desirable physical and mechanical qualities and enhance polymer-polymer compatibility.

The compatibilization effect’s physical basis

Compatibility’s physical characteristics may be distilled into three categories: In order to stabilize the performance of the blended modified plastic, it is necessary to: ①reduce the interfacial tension between the blending components; ② increase the stability of the phase structure;③Improve the interfacial bonding between the components to enhance the performance of blended modified plastics and to facilitate the transfer of external field effects between components. It is envisaged that the compatibilizer would congregate in the interface region in order to completely perform its function. In actuality, a variety of factors influence how the compatibilizer is distributed in the mix system. In addition to compatibility, it is influenced by blending equipment, process circumstances, the quantity and technique of applying a compatibilizer, and other elements.

The compatibilizer selection criterion

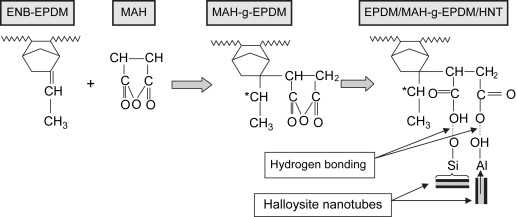

Block copolymers, graft copolymers, etc. are frequently employed as compatibilizers; with these materials, one component interacts or reacts with one component of the mix, and the other component interacts or reacts with a different component. The compatibilizers used are classified into homogeneous type compatibilizers and microphase separation type compatibilizers based on how they behave during microphase separation. The former category includes block copolymers and graft copolymers, while the latter category includes random copolymers, functionalized polymers, and homopolymers.

(1) Poly(A-co-B) copolymers of the polymers Poly(A) and Poly(B) can be utilized to make them compatible with one another.

(2) Poly(C) can be used directly as a compatibilizer for both Poly(A) and Poly(B) if it is compatible with both.

(3) Poly(C) can be utilized as a compatibilizer for both if it reacts with a certain functional group of Poly(B) and is compatible with Poly(A).

3. Systems for several widely used plastic blends that are compatibilizers

PPO/nylon 6 alloys include PPO-g-MAH and PS-g-MAH.

PC/ABS alloy: ABS, SEBS-g-MAH, SMA, or SBS.

PE, PP, POE, SEBS or ABS, EPDM-g-MAH : Elastomer hardened nylon 6 system

PBT/ABS alloy: acrylate copolymer; Styrene-based elastomer toughened PPO: SBS, SEBS, or SIS-g-MAH; Elastomer toughened PBT: acrylate copolymer, GMA graft copolymer

The goal of plastic modification by mixing

1.Expand the range of applications for plastics by improving certain of their physical and mechanical qualities.

(1)Utilize the unique qualities of each polymer component, learn from one another, get rid of each one’s flaws, keep their unique benefits, and you’ll end up with a polymer material with fantastic overall features. For instance, the combination of polypropylene and polyethylene maintains the benefits of high tensile strength, high compressive strength, and high impact strength of the former while overcoming the drawbacks of low impact strength and stress cracking resistance of the latter.

(2) Increase impact resistance and plastic toughness. To significantly modify another polymer, a modest quantity of a certain polymer can be employed as a modifier. The most common examples are polymers that have rubber coatings. PVC/rubber, PP/rubber, and other blend systems, for instance, offer strong impact resistance. Another example is the PA/PE blend system, which significantly lowers PA’s hygroscopicity and increases low temperature lower impact strength.

(3) Increase polymers’ capacity to withstand heat. Most plastics have a low thermal deformation temperature, making them unsuitable for particular components that only function at a specific temperature. Its heat resistance can be increased by combining other polymers that have strong heat resistance.

(4) Decrease water absorption and enhance dimensional stability of the product. High PA water absorption rates make it simple to modify product size, however the PA/PE mix system significantly lowers PA water absorption rates.

(5) Enhance the effectiveness of stress cracking. For instance, altering PC using PE or ABS, etc.

(6) Enhance various mechanical and physical characteristics. include biocompatibility, damping, adhesion, weather resistance, wear resistance, air tightness, and chemical resistance (solvent resistance).

2. Boost melt fluidity and molding efficiency

In the field of aerospace research, for instance, high-temperature-resistant polymers are necessary, yet many of these plastics are challenging to form and process due to their high melting points and low melt fluidity. Technology blending can address this issue. For instance, polyimide (PI), which is insoluble and refractory, may be readily injected when combined with fluid polyphenylene sulfide (PPS).

The mixes of these two polymers are still excellent high temperature materials since they both have outstanding heat resistance. It is possible to increase fluidity and processability by combining PS with polyphenylene oxide (PPO) and ABS with PC. To increase the processability of stiff PVC, it is frequently essential to add CPE, ACR, and other resins. Blending is another method for controlling how crystalline polymers behave when they crystallize.

3. Create new plastic alloy materials and provide plastics certain particular characteristics.

It may be used with flame-resistant polymers that contain halogens to create flame-retardant plastic alloys. For instance, PVC, chlorinated PE, polyphenylene ether, and polyphenylene sulfide may all be made more flame resistant by adding PS, ABS, polyoxymethylene, etc. Low conductivity characterizes polymers. To create plastic materials with anti-static, conductive, and electromagnetic shielding properties to meet the needs of the electronics, home appliance, communications, military, and other industries, some materials that require conductivity and anti-static can be blended with conductive polymers. requirements.

Differing polymers with markedly differing optical characteristics can be mixed to create beautiful plastics with pearly shine. One method for doing this is by adding polymethyl methacrylate to PC. It is possible to create polymer materials with good self-lubricating qualities by blending silicone resin with a variety of other polymers to take advantage of its lubricity.

A multi-layer, porous material with lovely natural wood grain is created by foaming two resins that have differing tensile strengths and low miscibility. This material may be used in place of wood since it is porous and has several layers.

4. Lower material costs and boost economic advantages

Combining certain pricey, high-performance engineering plastics with less expensive general-purpose plastics can save material costs and enhance molding processability without altering the conditions of use. For instance, performance may be increased and material costs can be decreased by combining ABS and SAN with PC and PSF.

5. Using recycled polymer waste to lessen environmental harm

Utilizing blending technology also allows for the recycling of discarded plastics, which saves resources and lessens environmental damage. In summary, blending modification can increase the overall performance of plastics, increase the variety of plastics with relatively little investment, increase the use of plastics, lower the cost of plastics, and increase the use of polymer materials. Additionally, high performance, refinement, functionalization, and specialization and serialization encourage the growth of the polymer materials industry, the plastics industry, and the development of high-tech industries.