When it comes to the relationship between PPO and PA66 and GF, we will slowly give you the story.

PA66 has a high reputation in the automotive, textile, machinery, chemical, electrical and electronic, aviation, metallurgy and other fields, and it has many advantages such as strong mechanical properties, wear resistance, good self-lubrication, corrosion resistance and good gas barrier. But there are also some disadvantages, low temperature and dry state impact strength, particularly sensitive to temperature, high water absorption easily lead to poor dimensional stability of products.

There is no such thing as a perfect person, everyone has shortcomings. In the face of shortcomings, the wise PA66 seeks out its partner GF. the advantages of GF’s high tensile strength help PA66 to make up for its own shortcomings and make PA66 more respected in the industry.

(ppo granules)

PPO, nicknamed polyphenylene ether, another leader in the industry, also has its own unique advantages, such as excellent physical and chemical properties, heat resistance, electrical insulation, water resistance and excellent dimensional stability, and most importantly, it also has the advantages of strong mechanical strength, good creep resistance, rigidity and so on.

Therefore, we all hope that PA66, GF and PPO can be a strong combination, but PA66 and PPO are difficult to reconcile with each other, PA66 is a polar crystalline polymer and PPO is a non-polar amorphous polymer, these characteristics make it difficult for them to work together.

Fortunately, however, a young man from the industry was willing to take on the role of peacemaker ……

CS-1

PPO-g-MAH, which can be used as a compatibilizer for PPO/PA/GF alloys, can effectively improve the compatibility and dispersion between the components and increase the tensile strength and impact properties.

Experimental cases

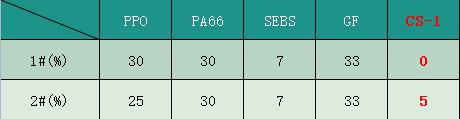

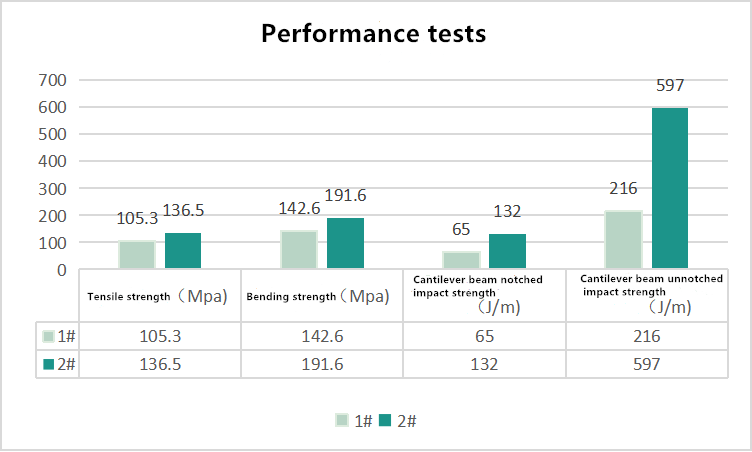

Mechanical properties of PPO/PA66/GF systems without and with CS-1

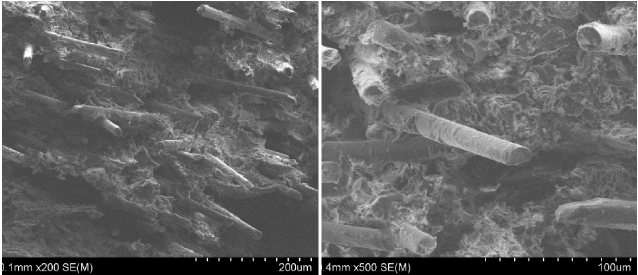

Experiment 1# Microscopic morphology at different magnifications

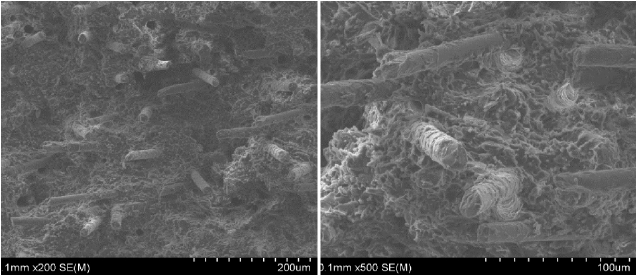

Experiment 2# Microscopic morphology at different magnifications

As can be seen from the graph, the addition of 5% CS-1 results in a rougher GF surface and an increase in the overall resin coverage, indicating a further increase in compatibility between GF and the base resin. This indicates that the addition of PPO-g-MAH can further improve the compatibility between GF and the base resin in the PPO/PA66/GF system.