Введение

High voltage cables’ insulating layer is essential for ensuring dependable and secure power transfer. As a novel material for high voltage cable applications, EPDM-g-MAH has been developed to fulfill the demand for superior insulation materials.

The benefits of EPDM-g-MAH

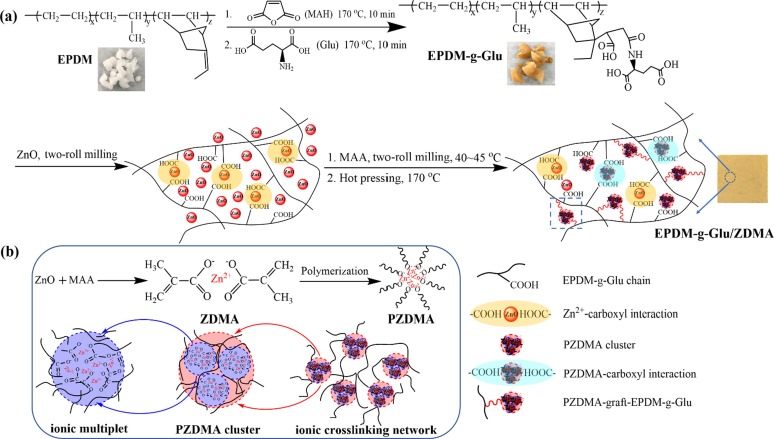

An innovative polymer called EPDM-g-MAH combines the use of maleic anhydride grafting with EPDM rubber. The grafting process improves the material’s mechanical and electrical qualities by enhancing the compatibility of polar fillers with EPDM rubber.

The typical high voltage cable materials XLPE and EPR have certain distinct benefits over EPDM-g-MAH. First of all, EPDM-g-MAH is more heat resistant. It has a maximum temperature tolerance of 150°C, which is substantially greater than that of XLPE and EPR. Second, EPDM-g-MAH has outstanding resistance to oxidation and aging. It can continue to function well mechanically and electrically even when exposed to heat, humidity, and sunshine. Additionally, EPDM-g-MAH has better electrical insulating qualities as a result of the polar groups that maleic anhydride introduces.

EPDM-g-MAH Application Features

Due to its special application characteristics,EPDM-g-MAHis a good choice for high voltage cable insulation. First off, it performs well in terms of processing. It is necessary for creating various sorts of high voltage cables since it can be extruded and molded into a variety of forms and sizes. In addition, it possesses strong mechanical qualities including tear resistance, elongation at break, and tensile strength. High voltage cables’ dependability and safety are ensured by these characteristics. Thirdly, because EPDM-g-MAH adheres well to metal and other materials, the cable construction will be stable.

Application of EPDM-g-MAH in High Voltage Cables

High voltage cables can either have EPDM-g-MAH as the insulation layer directly or as a jacket to shield the insulation layer from mechanical harm and environmental influences. The applications of EPDM-g-MAH in high voltage cables are illustrated in the following instances.

1. high-voltage cable made of XLPE.

The insulating layer of 230kV XLPE high voltage cables is made of EPDM-g-MAH. High voltage electricity is transmitted across vast distances using these lines. For this application, EPDM-g-MAH is the best material since it has great electrical insulating qualities and can endure high temperatures.

2. offshore wind power cable at 35 kV

The jacket layer of 35kV offshore wind power cables is made of EPDM-g-MAH. Because these cables are used in hostile marine settings, the insulating layer needs to be protected by a strong, robust substance. Because EPDM-g-MAH has outstanding mechanical characteristics and adhesion performance, the cables will be dependable and long-lasting.

3. 10kV cable made of cross-linked polyethylene

The insulating layer of 10kV cross-linked polyethylene cables is made of EPDM-g-MAH. Many urban electricity distribution networks employ these connections. Due to its better resistance to aging and ozone, the use of EPDM-g-MAH protects the electrical safety of the cables and increases their service life.

Заключение

In conclusion, EPDM-g-MAH holds promise as a high voltage cable insulation material. It is superior to conventional materials used for high voltage cables because of its distinctive benefits and application qualities. It has shown good performance and dependability in high voltage cables such 230kV XLPE high voltage cables, 35kV offshore wind power cables, and 10kV cross-linked polyethylene cables. It is anticipated that EPDM-g-MAH will have more potential applications and be crucial in advancing high voltage cable technology in the future.