Описание товара

W1H is a general-purpose HDPE-G-MAH product with excellent comprehensive properties. It contains maleic anhydride and has strong plasticity, which can improve the properties of polymerization and matrix minerals, and the surface roughness of inorganic substances, reaching The effect of enhancing the strength of composite materials.

By enhancing compatibility, mechanical characteristics, and processability in polymer blends, the Universal HDPE-G-MAH Compatibilizer for Polyolefin Materials provides outstanding value and performance. This compatibilizer transforms the compatibility and performance of polyolefin blends with its distinctive HDPE-G-MAH structure, improved interfacial adhesion, and broad range of application compatibility. Buyers in a variety of industries, such as consumer products, packaging, construction, and automotive, can gain improved compatibility, excellent mechanical qualities, a wide processing window, and cost-effectiveness by integrating this compatibilizer into their manufacturing processes. The compatibilizer is a highly attractive option for producers looking to improve cost-effectiveness, compatibility, and performance in polyolefin blend applications because of its remarkable features and benefits.

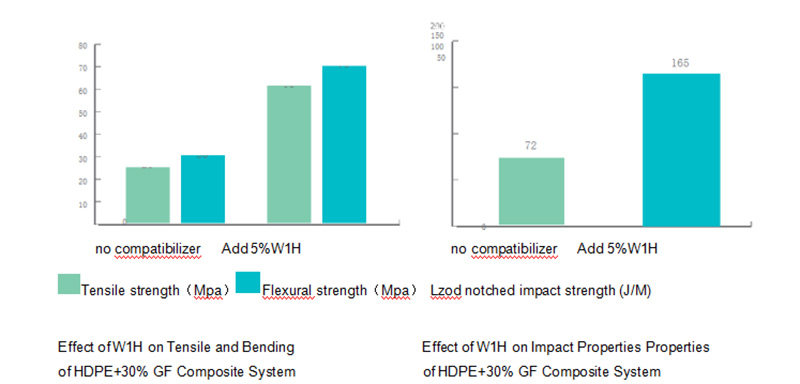

Application effect of W1H in glass fiber (30%) reinforced HDPE:

Примечание:HDPE raw material uses DOW K T 10 0 0, glass fiber uses Jushi 98 8 A

It can be seen from the figure that in the 30% glass fiber reinforced HDPE system, adding 5% Kolibang®W1H can greatly improve the tensile strength, bending strength and notched impact strength of the material system, and the coupling effect is remarkable.

Передовое оборудование!

Оснащен передовыми производственными линиями и экспериментальным испытательным центром для обеспечения качества продукции.

Сильная техническая сила!

Более 10 опытных технических специалистов по исследованиям и разработкам обеспечивают непрерывные инновации.

Рекомендация Техническая поддержка Послепродажное обслуживание

Характеристика

| Тестовые задания | Данные испытаний | Метод обнаружения |

| плотность | 0,95 г/см³ | ASTM D792 ISO 1183 |

| температура плавления | 130℃(266℉) | ASTM D3418 ISO 3146 |

| Расплавить палец | 1-3(190℃,2.16kg)g/10min | ASTM D1238 ISO 1133 |

| Количество прививок | Высокая | кислотно-основное титрование |

| Внешний вид | частицы |

W1H - это продукт общего назначения HDPE-G-MAH с превосходными комплексными свойствами.

- HDPE-G-MAH Structure: The compatibilizer is made of high-density polyethylene (HDPE) with a grafted maleic anhydride (MAH) structure connected to the backbone. The compatibility and interfacial adhesion of different polyolefin materials in blends are improved by this special structure.

- Enhanced Interfacial Adhesion: Polyethylene (PE) and polypropylene (PP), two incompatible polyolefin materials, are made to adhere to one another more strongly by using the HDPE-G-MAH compatibilizer. By establishing a compatible interface, it lessens phase separation and enhances the mechanical characteristics of blends of polymers.

- Better Thermal resilience: The compatibilizer can tolerate high processing temperatures without degrading because of its outstanding thermal resilience. This feature guarantees compatibility and reliable performance across a range of manufacturing methods.

- Flexible Application Compatibility: A broad variety of polyolefin materials, such as PE and PP, and their different grades, are compatible with the Universal HDPE-G-MAH Compatibilizer. Because of its adaptability, it can be integrated into a variety of polymer systems to provide specialized solutions for certain application needs.

Преимущество

- Improved Compatibility: By considerably enhancing the compatibility between various polyolefin materials, the HDPE-G-MAH compatibilizer makes it possible to create polymer blends with uniform structures and better mechanical qualities. It improves interfacial adhesion, minimizes phase separation, and maximizes the performance of the finished product.

- Better Mechanical Properties: The compatibilizer makes polyolefin blends have better mechanical properties by lowering phase separation and increasing interfacial adhesion. More elongation at break, impact resistance, and tensile strength are increased, making the products stronger and longer-lasting.

- Extrusion, injection molding, blow molding, and other production processes are all supported by the compatibilizer’s large processing window, which is made possible by its exceptional temperature stability and varied compatibility. It offers producers adaptability and processing simplicity in a range of production settings.

Наше преимущество

Глобальная цепочка поставок!

Система цепочки поставок Sound Storage And Logistics

Техническая поддержка

Послепродажная защита

Фокус - Достижение - Превосходство!

Продукция на заказ

Фокус на НИОКР

Глобальные услуги

Сертификация Coace!

Сертификация ISO9001:2015

Сертификация ISO14001:2015

Регистрация в ЕС REACH

Предварительная регистрация на K-REACH в Корее

Преимущество предприятия!

Укладка в стране и за рубежом, прекрасная для смешивания

Схема внутреннего маркетинга

Схема зарубежного маркетинга

Приложение

1. Can be used as a compatibilizer for low-smoke halogen-free flame retardant cable materials;

1. Can be used as a compatibilizer for low-smoke halogen-free flame retardant cable materials;2. It can be used as a surface improver for extruded sheets/plates, which can effectively improve the surface flatness of the material and eliminate the unevenness and pitting on the surface of the material;

3. It can be used as a compatibilizer for polyethylene and glass fiber to promote the compatibility of polyethylene and glass fiber;

4. It can be used as a compatibilizer for masterbatches with PE as a carrier, such as color masterbatches, flame retardant masterbatches, functional masterbatches, etc.;

5. It can be used as a modifier for extending the anti-fog period of anti-fog mulch.