▇ Polybutylene terephthalate (PBT)

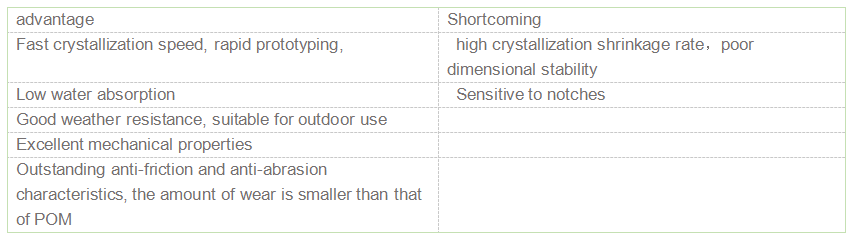

It is a relatively new type of thermoplastic engineering plastic developed and industrialized by the American Celanese company in the 1970s. It has the following characteristics:

PBT has many advantages, but its application is limited due to these two outstanding disadvantages.

▇ Acrylonitrile-butadiene-styrene plastic (ABS)

ABS resin is currently the plastic with the largest output and the most widely used, and the price is relatively cheap. It not only has the mechanical properties of toughness, hardness and rigid phase balance, but also has good dimensional stability, surface gloss, low temperature resistance, coloring processability and processing fluidity.

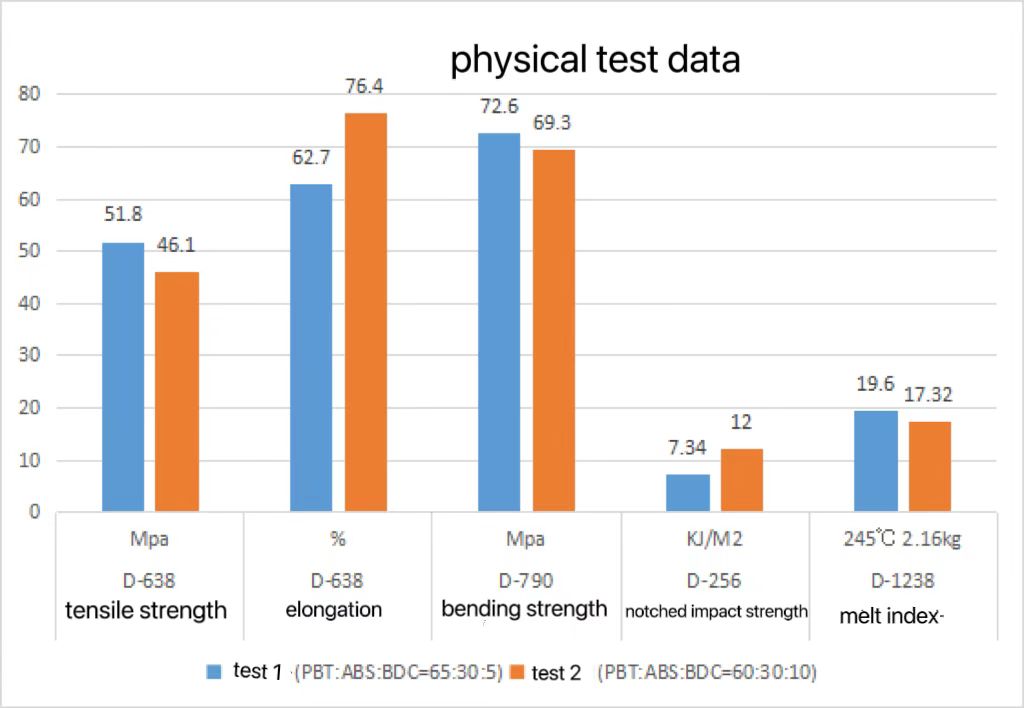

It can be expected that blending ABS/PBT can produce plastic alloys with excellent performance and realize high performance resin.

However, ABS/PBT alloy is an incompatible system, and the direct blending of the two is prone to delamination and peeling, and the material performance is poor. Therefore, the compatibilizer is the key to the preparation of ABS/PBT alloy.

Appropriate compatibilizers can produce high performance alloys.

Coace self-developed product——BDC can provide excellent compatibilization solutions for ABS/PBT alloys, maximizing the mechanical properties, thermal properties and electroplating properties of plastic alloy systems.