Products Description

Basic formula of low smoke halogen free flame retardant cable material

| formula | 1#(%) | 2#(%) |

| magnesium hydroxide/MH-8800 | 60 | 60 |

| LLDPE/FL201XV/Exxon Mobil | 20 | 15 |

| EVA/7350M/Formosa Plastics | 20 | 20 |

| W1L | 0 | 5 |

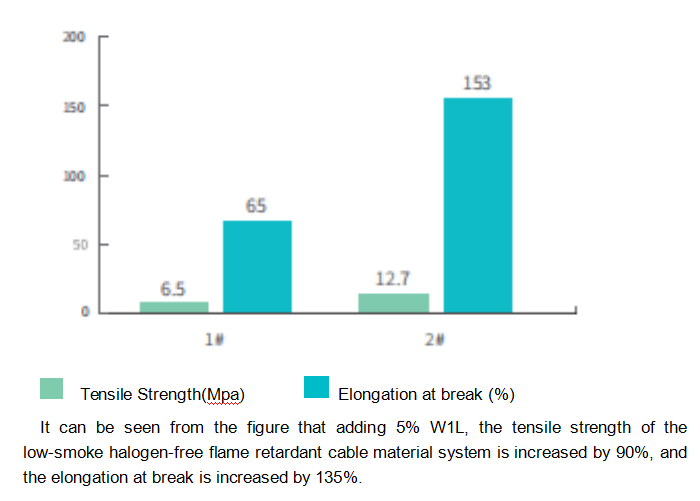

It can be seen from Figure 1 that the addition of 5% W1L increases the tensile strength of the low-smoke halogen-free flame retardant cable compound system by 90% and the elongation at break by 135%.

Improvement of tensile properties of low-smoke halogen-free flame retardant cable material

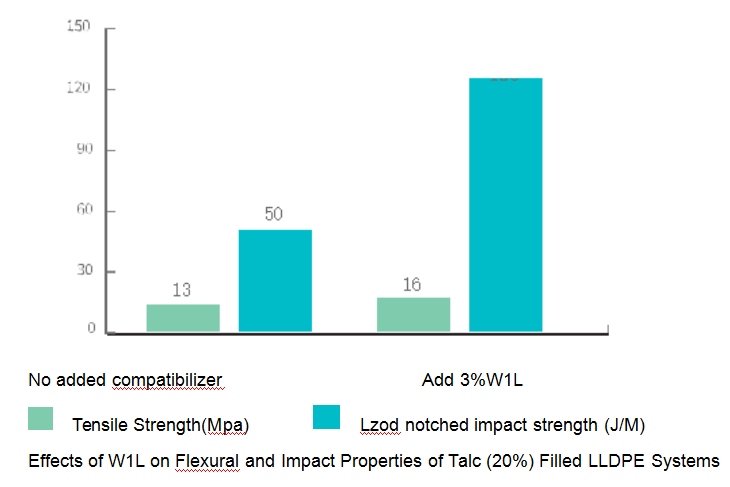

Application effect of W1L in talc (20%) filled LLDPE system

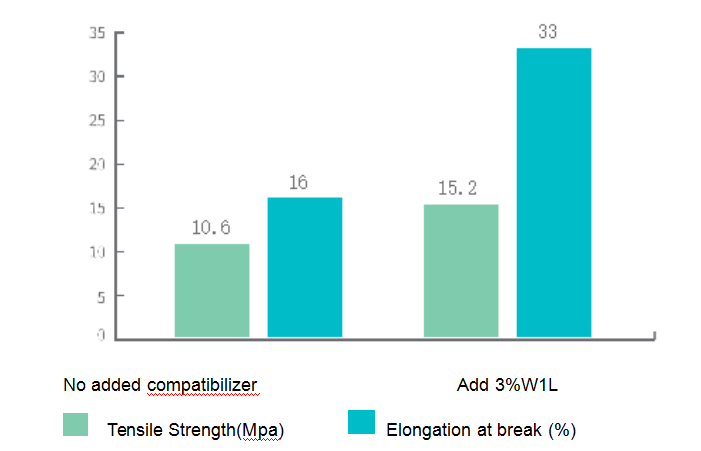

Effect of W1L on Tensile Properties of Talc (20%) Filled LLDPE System

It can be seen from the figure that in the LLDPE system filled with talc (20%), adding 3% W1L can greatly improve the tensile strength, flexural strength and notched impact strength of the material system.

Suggested dose:The dose (5-25%) may be increased or decreased properly according to the toughness requirements and by taking the cost into consideration.3-10% shall be adopted for PA6/PA66 reinforcing and toughening, while 5% shall be adopted for the compatibilizer of nylon and polypropylene/polyethylene alloy.

Packaging, storage and transportation:20kg kraft bag with internal plastic bag. This product shall be treated as non-hazardous article and be stored or transported under dry conditions, and sunlight and rain shall be avoided.

Characteristic

W1L is a method of chemical reaction to connect maleic anhydride molecules on the linear low-density polyethylene molecular chain, so that the polyethylene end has the re-reactivity and strong polarity of maleic anhydride polar molecules, so it can improve polyolefin. The interface affinity between the substrate and inorganic substances such as metal powder, glass fiber, wood powder, mineral powder, starch, etc., so as to enhance the strength of the composite material, and is often used as a compatibilizer for polyolefin materials. When this product is used in low-smoke halogen-free flame retardant cable compound, it can improve the compatibility and adhesion between polyolefin matrix and inorganic flame retardant interface. Improve the dispersibility and compatibility of magnesium hydroxide and aluminum hydroxide, so as to maximize the flame retardancy of cable materials, reduce smoke index, smoke generation, calorific value and carbon monoxide generation, increase oxygen index, improve dripping Falling properties, etc., improve the mechanical properties of materials. This product can also be used as a surface improver for extruded sheet or extruded sheet, which can effectively improve the surface flatness of sheet or sheet, and eliminate unevenness and pitting on the surface of the material.

Advanced Equipment!

Equipped with advanced production lines and experimental testing center to ensure product quality.

Strong Technical Force!

More than 10 experienced technical R&D staff drive continuous innovation.

Advantage

(1) High flame retardant efficiency, which can endow plastic materials with good flame retardancy;

(2) It has good compatibility with plastic resins and can be well dispersed in resins to form a homogeneous system;

(3) Does not decompose at the processing temperature of the plastic;

(4) Do not reduce the mechanical properties, electrical properties, weather resistance, etc. of plastics;

(5) It has good durability and can be kept in plastic for a long time to play a flame-retardant role;

(6) Non-toxic, odorless, and pollution-free, no toxic gas is produced during the flame-retardant process, and no secondary pollution occurs.

Our advantage

Global Supply Chain!

Sound Storage And Logistics Supply Chain System

Technical Support

After-sales protection

Focus • Achievement • Excellence!

Products Customized

Focus on R&D

Global Services

Coace Certification!

ISO9001:2015 Certification

ISO14001:2015 Certification

EU REACH registration

Korea K-REACH pre-registration

Enterprise advantage!

Layout at home and abroad, wonderful for mixing

Domestic marketing layout

Overseas marketing layout

Application

1. it Can be used as a compatibilizer for low-smoke halogen-free flame retardant cable materials;

1. it Can be used as a compatibilizer for low-smoke halogen-free flame retardant cable materials;

2. It can be used as a surface improver for extruded sheets/plates, which can effectively improve the surface flatness of the material and eliminate the unevenness and pitting on the surface of the material;

3. It can be used as a compatibilizer for polyethylene and glass fiber to promote the compatibility of polyethylene and glass fiber;

4. It can be used as a compatibilizer for masterbatches with PE as a carrier, such as color masterbatches, flame retardant masterbatches, functional masterbatches, etc.;

5. It can be used as a modifier for extending the anti-fog period of anti-fog mulch.