Products Description

K2G is a general-purpose EVA-g-MAH product with excellent comprehensive properties.EVA-g-MAH can be used as a film for hot-pressing bonding wood, and the bonding can be completed at a lower hot-pressing temperature. The following is Comparison table of bonding strength of EVA-g-MAH film to poplar board.

EVA grafted maleic anhydride can be used as a film for hot-pressing bonding wood, and the bonding can be completed at a lower hot-pressing temperature. The following is Comparison table of bonding strength of EVA-g-MAH film to poplar board.

EVA-g-MAH (ethylene-vinyl acetate-graft-maleic anhydride) is a type of copolymer that is commonly used in various industrial applications. One of its applications is as a film for hot-pressing bonding wood. This copolymer has been found to be effective in improving the bonding strength of wood and reducing the hot-pressing temperature required to complete the bonding process.

The use of EVA-g-MAH as a bonding film for wood has several advantages. First, it has good adhesion properties, which allows it to bond well with wood substrates. Second, it has a low melting point, which means that it can be hot-pressed at a lower temperature compared to other bonding agents, thereby reducing the energy required for the process. Third, it is a thermoplastic material, which means that it can be melted and reshaped multiple times without losing its properties, making it a suitable material for recycling.

Overall, the use of EVA-g-MAH as a bonding film for wood is a promising development that can lead to more efficient and environmentally friendly bonding processes in the wood industry.

High adhesive performance and a low melting point make General EVA Grafting Maleic Anhydride Products stand out in terms of features, benefits, and applications. These additives improve the bonding strength and adhesion performance of EVA copolymers due to their low melting point characteristic and superior adhesive qualities. Maleic anhydride grafting ensures compatibility and better physical qualities, leading to end products that are robust and long-lasting.

Advanced Equipment!

Equipped with advanced production lines and experimental testing center to ensure product quality.

Strong Technical Force!

More than 10 experienced technical R&D staff drive continuous innovation.

Characteristic

| Product models | K2G | K2B | K2L |

| Melting index | 15-30 | 2-8 | 2-6 |

| Grafting rate | High | High | High |

| performance | High flow | high adhesion | high strength, high adhesionComposite hot melt adhesive,

hydrolysis resistance, high adhesion |

NOTE: The above data are typical test values and should not be interpreted as a specification low < 0.4wt %, medium 0.4-0.8 wt%, high > 0.8wt%

Comparison parameters of different applications

Adhesion effect of EVA raw material film and K2G film

| model | bond strength/MPa | remark |

| EVA-VA28 | 0.264 | —- |

| K2G | 1.625 | interface tearing |

As can be seen from the above table, because the MAH in EVA-g-MAH reacts with the hydroxyl groups in the wood fiber, a mutual entanglement structure is formed through chemical bonds, which increases the cohesion force, the interface is torn, and its cohesion force is increased. 516% higher adhesion than EVA raw material.

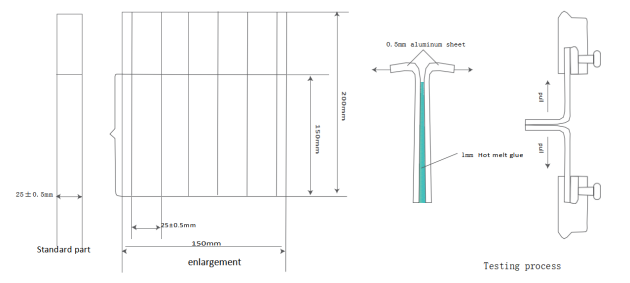

T-type peel strength test (aluminum sheet)

| Model | T-peel strength N/25mm |

| EVA-VA28 | 160 |

| foreign competitors EVA-g-MAH | 258 |

| K2G | 252 |

Figure 1: T-type test (aluminum sheet) standard parts and test process sketch

Advantage

- Low Melting Point: The low melting point of the General EVA Grafting Maleic Anhydride Products makes processing and integration into EVA copolymers simple. Performance is enhanced by this characteristic, which guarantees effective mixing and compatibility with various materials.

- High Adhesive capability: When added to EVA copolymers, these goods offer a high degree of adhesive capability. They are appropriate for applications requiring strong and dependable bonding because they improve the adhesion and bonding strength.

- Maleic anhydride grafting: Maleic anhydride grafting is used in the formulation of the General EVA Grafting Maleic Anhydride Products. Improved dispersion and compatibility within the polymer matrix result from this grafting process, which improves the additives’ compatibility with EVA copolymers.

- Better Physical Properties: These products improve the physical properties of EVA copolymers by grafting with maleic anhydride. They increase impact resistance, tensile strength, and flexibility, which increases the finished goods’ resilience and durability.

- Versatile Uses: The General EVA Grafting Maleic Anhydride Products are used in a wide range of sectors. They can be used as modifiers for EVA-based films, sheets, and molded products, as well as adhesive formulations, sealants, and coatings.

Our advantage

Global Supply Chain!

Sound Storage And Logistics Supply Chain System

Technical Support

After-sales protection

Focus • Achievement • Excellence!

Products Customized

Focus on R&D

Global Services

Coace Certification!

ISO9001:2015 Certification

ISO14001:2015 Certification

EU REACH registration

Korea K-REACH pre-registration

Enterprise advantage!

Layout at home and abroad, wonderful for mixing

Domestic marketing layout

Overseas marketing layout

Application

Typical application

Typical application

Hot melt adhesive series, mainly used for film blowing, extrusion, hot melt adhesive,

solvent-soluble glue, surface treatment accelerator, etc. High grafting rate, good polarity,

and excellent adhesion to metals, aluminum, and other substrates.

When used as a surface treatment agent, it can improve metals, polyester, PP, PE, EVA

and other materials. Improve the surface adhesion, increase the adhesion and adhesion.

To be used as the adhesive for composite structure materials, which contain the matel-plastic panels, muli-layers, etc.

To be used as compatibilizers for EVA compounds, and other masterbatch.