Production process – understanding screw components

This time we will continue the last topic. The third important factor for nylon toughening is the production process. A big factor in the production process is the screw combination, because the twin-screw extruder we use is usually It is a building block, which means that the combination of threaded elements can be adjusted according to our production needs.

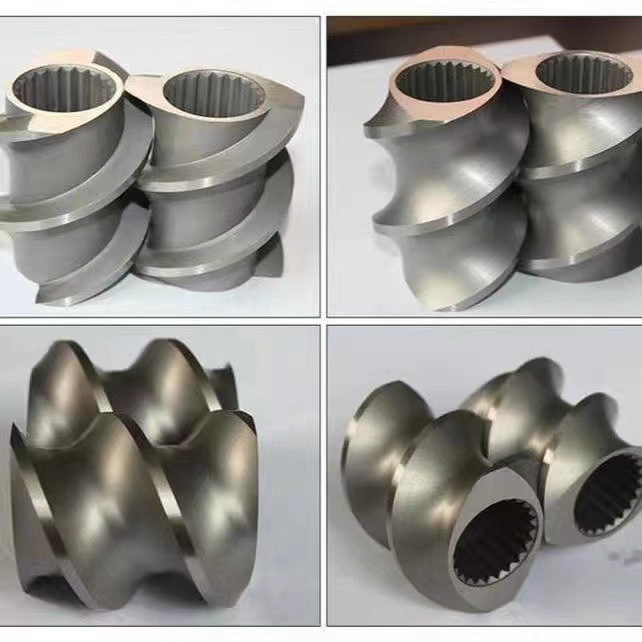

Before talking about the screw combination, let’s first get to know the threaded elements of the twin-screw. I will generally divide the threaded elements of the twin-screw into three categories.

Before talking about the screw combination, let’s first get to know the threaded elements of the twin-screw. I will generally divide the threaded elements of the twin-screw into three categories.

First of all, the first type is the conveying screw element, also called the conveying block. As the name implies, the conveying block mainly plays the role of compressing and conveying the material during the extrusion process. For the conveying block, we usually pay attention to it. The length, the extension lead, the direction and whether it is single-ended, double-ended or long-ended.

(threaded element – conveyor block)

The second category is the shear block, also called the shear thread element. The main function of this type is to plasticize and disperse the material in the basic process, and to shear and disperse the glass fiber. Cutting block, we will focus on several important characteristics of it, such as a length of its single piece, or thickness, then an angle between pieces, and then a length of the entire threaded element, including shear Cut in one direction and so on for these indicators.

(Threaded elements – cutouts)

The third category is mainly some special threaded elements, because with the continuous development and development of twin-screw extruder manufacturers, there are many special threaded elements that can be seen in the market now, which also endows the twin-screw There are a lot of special functions, so there are many common threaded components such as mixing rotor, SME, TME, ZME, etc. There are so many threaded components, so how do we go further? Know it, we will share it in the next section.