Nylon film has the advantages of light weight and easy processing, making it the preferred barrier material, but its application is limited by its poor gas barrier properties.

Graphene is a material with a two-dimensional mesh structure and has excellent gas barrier properties.

In this paper, modified graphene oxide (mGO-ODA) was produced by reducing graphene oxide (GO) with octadecylamine (ODA) and compounded with polypropylene maleic anhydride graft (MAPP) to prepare a series of mGO-ODA/MAPP composites as coatings.

Later, the coating materials were laminated onto the nylon film by spraying technique to obtain a nylon composite film with excellent gas barrier properties.

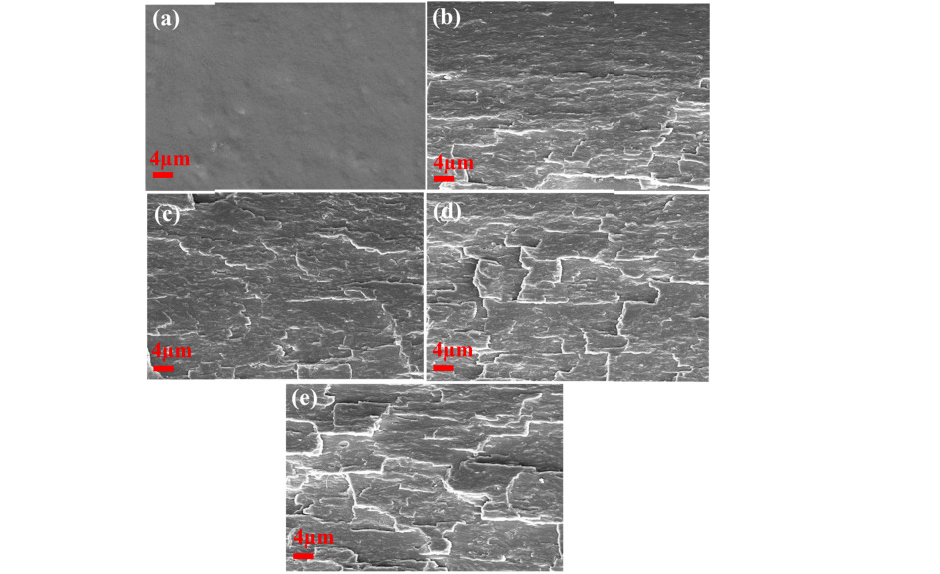

Figure (1) SEM images of tensile sections of (a) pure MAPP; (b) 15% mGO-ODA/MAPP; (c) 30% mGO-ODA/MAPP, (d) 45% mGO-ODA/MAPP; (e) 60% mGO-ODA/MAPP

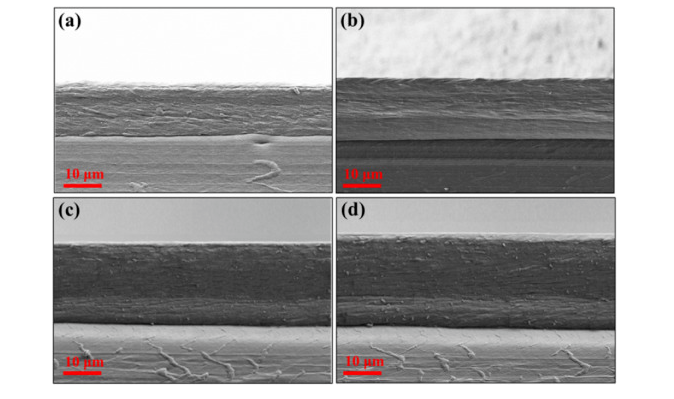

Figure (2) SEM images of cross-sections of (a) 15%mGO-ODA/MAPP; (b) 30%mGO-ODA/MAPP; (c) 45%mGO-ODA/MAPP; (d) 60%mGO-ODA/MAPP nylon composite films

Figures 1 and 2 show the SEM images of cross-sections of coated materials with different mGO-ODA contents and composite films, respectively. From Figure 1, it can be seen that the cross-sections of pure MAPP are very smooth, while the cross-sections of all composites are rough, which indicates that the mGO-ODA in the composites is well compatible with MAPP and the mechanical properties are improved.

And Figure 2 shows the good adhesion between the nylon film and the coating due to the hydrogen bonding and chemical bonding between the end groups of nylon and the anhydride part of MAPP.

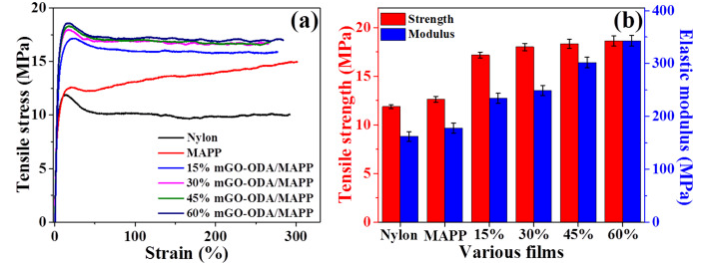

Fig. (3) (a) Tensile stress-strain curves of different types of coatings, MAPP and nylon composite films; (b) elastic modulus diagram

Figure 3 shows the tensile stress-strain curves (a) and elastic modulus diagrams (b) for different types of coatings, MAPP and nylon composite films.

The figure shows that the tensile strength and elastic modulus of the nylon composite film are greatly improved compared with the nylon film, and they increase with the increase of mGO-ODA content, which indicates that MAPP can improve the tensile strength and elastic modulus of the nylon film, and at the same time, graphene oxide also enhances the mechanical properties of the nylon composite film through the good interfacial bonding between MAPP and nylon.

Gas barrier experiments and electrochemical corrosion experiments proved that the H2 and O2 barrier properties and corrosion resistance of the nylon composite film were improved.