PP-g-MAH (Polypropylene-grafted-Maleic Anhydride) has been a game-changing addition to the world of polymer additives. The performance and adaptability of polypropylene (PP) are improved by this multi-functional polymer addition, making it a popular option across a number of sectors. With its enhanced durability and melt grafting characteristics, PP-g-MAH provides a wide range of applications while also taking environmental sustainability into account. We examine the many uses of PP-g-MAH in this article and emphasise its unique qualities as a significant polymer modifier.

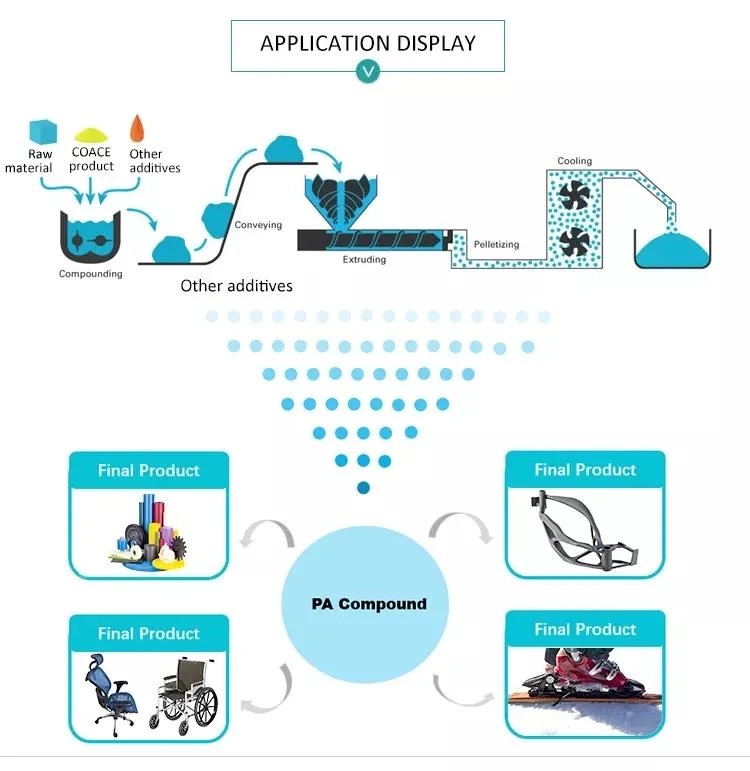

Application Scope: PP-g-MAH is widely used in a variety of sectors, including the automotive, packaging, building, and consumer products industries. It is widely sought-after for the production of durable consumer goods, packaging, pipelines, and automotive components due to its capacity to improve the performance of polypropylene. The wide range of applications demonstrates how this polymer additive may be tailored to fit a variety of industry demands.

Durability and Multi-Functionality: PP-g-MAH stands out for its versatility, which enables it to enhance the mechanical and thermal characteristics of polypropylene. Maleic anhydride is grafted onto polypropylene to improve the polymer’s adhesion, compatibility, and processability. As a result, the finished product has better impact resistance, tensile strength, and general durability. Manufacturers may rely on PP-g-MAH to improve the mechanical qualities and performance of their products.

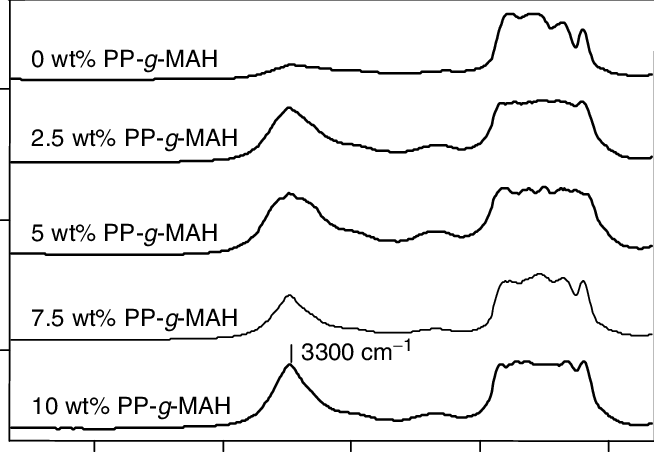

Improved Reactive Extrusion Method: To make it easier to graft maleic anhydride onto polypropylene, the conventional twin-screw reactive extruder has received considerable advancements. To improve the melt grafting process, studies have concentrated on supplementary grafting monomers and initiators with various half-lives. The necessary grafting efficiency is achieved by adding supplementary grafting monomers, which effectively prevent the breakdown of macromolecular free radicals during the grafting process. Additionally, using initiators in stages has shown to have synergistic effects that increase grafting effectiveness and reduce leftover maleic anhydride.

Environmental friendliness: In contemporary industry, sustainability has taken the lead. This issue is addressed by the environmentally friendly features of PP-g-MAH. Manufacturers can assure the effective utilisation of maleic anhydride and minimise waste by optimising the grafting process and lowering residual. Additionally, the improved durability and performance of polypropylene made possible by PP-g-MAH extend the useful lives of products, lowering the need for constant replacements and fostering sustainability.

Polymer Modifier: A crucial polymer modification, PP-g-MAH enables the development of new materials with exceptional characteristics. It expands the range of potential products by improving the adherence and compatibility of polypropylene. By adding PP-g-MAH to polypropylene composites, manufacturers may develop novel solutions that enhance the material’s overall performance and strength. This makes it possible for high-quality and high-value goods to be developed across several sectors.

The world of polypropylene has undergone a revolution because to PP-g-MAH’s outstanding range of applications, multifunctionality, durability, and environmental friendliness. It is an essential polymer addition for several sectors because to its capacity to improve the mechanical and thermal characteristics of polypropylene. PP-g-MAH offers higher grafting efficiency and lower residue thanks to improved reactive extrusion methods and an emphasis on environmental sustainability, which adds to its attractiveness. PP-g-MAH opens the door for novel product creation as the need for sophisticated materials rises, allowing producers to fully utilise polymers.