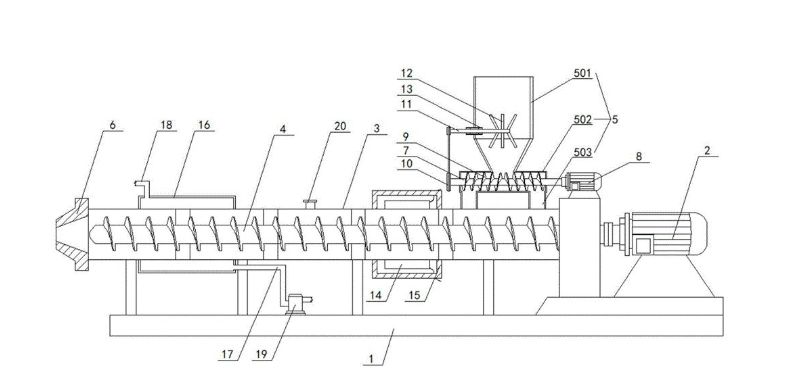

The third factor of nylon toughening – the determination of the production process, that the nylon toughening modification, it is usually used twin-screw blending modification, that twin-screw blending modification of course involves a twin-screw extruder, then how do we know and understand the twin-screw extruder it.

●Twin-screw extruder torque level

Generally speaking, the higher the torque rating, the better it is for modification.

When the output torque of the two screws is higher, the amount of material passed per unit time will be higher, which means that the more material passed per unit time, the lower the parallel shear rate will be.

That achieve the same plasticization effect, it will be less damage to the performance, so the same this case, the nylon made in the toughened material, the final performance is better.

●Length to diameter ratio of twin-screw extruder

As for the aspect ratio, I think the aspect ratio suitable for nylon toughening can be 40:1, 44:1, or 48:1, in fact, we don’t need to care too much about the length of the aspect ratio. A proper 40:1 or more is enough for us to arrange our screw combination.

When the aspect ratio is longer, it has a longer residence time, but we can also adjust the screw combination to make it more dispersion of shear, in fact, it is also more conducive to the final effect of a modified nylon toughening.