01 Enhancer

Reinforcing agents can significantly improve the strength and rigidity of materials, most of which are high-strength, fibrous inert substances, such as glass fiber and carbon fiber, among which the amount of glass fiber is relatively large, because it is white, it can be adjusted according to the color of the product, and used It is also very convenient to get up.

02 Filler

The purpose of adding an inert material to the material is to increase the quality and reduce the cost. It can also improve the processing performance and some physical properties of the material such as shrinkage, strength, temperature resistance, and corrosion resistance. Here we often use activated calcium carbonate, talcum powder, wollastonite, mica and so on.

03 Flame retardant

Flame retardant is a kind of auxiliary agent that can prevent combustion, and is mainly divided into two categories: additive type and reactive type. Additive flame retardants are subdivided into halogen-containing flame retardants and halogen-free flame retardants, which are usually added to materials in the form of additives, and are simply physically mixed with materials. The reactive type is more complicated, generally a monomer containing flame retardant elements and reactive groups in the molecule, which can be chemically bonded to the resin molecular chain and become a part of the resin. The reaction type is more complicated and costly, and it has not been widely used yet.

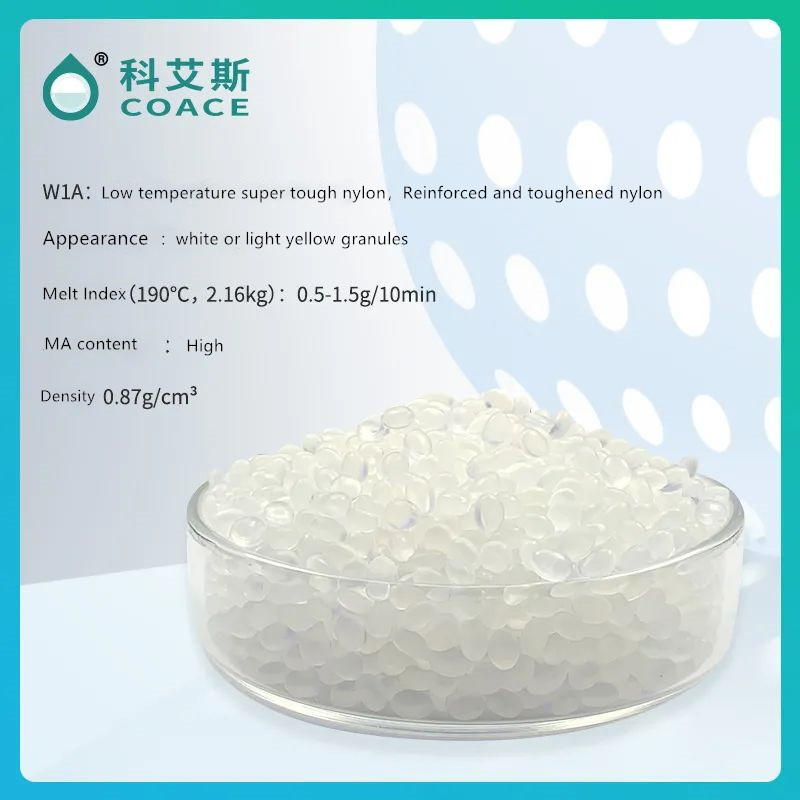

04 Toughener

It can improve the impact strength and toughness of materials, also known as toughening agent. We often use maleic anhydride grafted POE newly developed in recent years, and EPDM can also be selected according to the situation.

05 Plasticizer

Plasticizers can reduce the melting temperature, viscosity and hardness of materials, increase fluidity and softness, thereby improving the processing properties of materials.

06 Colorants and optical brighteners

The coloring agent is mainly to impart color to the material and make the product more beautiful.

The fluorescent whitening agent can effectively improve the appearance, and the effect is better when used together with the coloring agent.

07 Foaming agent

Foaming agents are substances that can generate gas and cause cells or voids in plastic products,and

are divided into physical foaming agents and chemical foaming agents.

The next big category is stabilizers, whose main function is to delay and stop the degradation of materials under the action of physical and chemical factors.

08 Heat stabilizers

Heat stabilizers can delay or avoid material damage and further degradation caused by heat. Usually not stated, the heat stabilizer refers specifically to the stabilizer used in the processing of polyvinyl chloride and vinyl chloride copolymers.

09 Light stabilizer

Light stabilizers mainly inhibit or weaken the photodegradation of plastics and improve the weather resistance of products. Ultraviolet rays in sunlight have the greatest damage to plastics. In addition, impurities or chromophores in polymers can also promote photooxidative degradation of polymers.

10 Antioxidant

Antioxidants can delay or inhibit the oxidative degradation of plastics, and are the most important type of plastic stabilization additives. Almost all polymeric resins involve the application of antioxidants. It is generally divided into primary antioxidants and auxiliary antioxidants. The main function of the primary antioxidant is to capture polymer peroxyl radicals. The auxiliary antioxidant has the function of decomposing polymer peroxygen compounds, also known as “peroxides”. Decomposer”.

Then there are processing additives, which can make the modified nylon easy to form or improve the forming effect during processing.

11 Lubricant

Lubricants can reduce the viscosity of plastics and reduce the friction coefficient between the modified nylon melt and processing equipment. They can be divided into two types: internal lubricants and external lubricants. Internal lubricants can reduce the friction of polymer molecules and reduce the high The viscosity of the polymer and reduce energy consumption; external lubrication reduces the friction and adhesion between the polymer and the processing equipment, usually the external lubricant is not compatible with the polymer.

12 Release agent

Similar to the external lubricant, a thin layer of high-efficiency release agent is formed between the product and the mold to make the product fall off by itself.

No matter how good the modified nylon is, it is inseparable from the help of modifying additives. It needs not only functional additives but also auxiliary additives. It can show its potential when it is matched with each other and used in an appropriate amount.