1.Polymer graft modification: what is it?

Free radical polymerization is a modification technique called "polymer graft modification" that adds polar or functional side groups to the polymer chain. The polymer has exceptionally high polarity or a unique functional group after graft modification, which may enhance the polymer's adherence and printability and be utilized as a compatibilizer, toughener, and other functional materials, among other things.

Melting, solution, suspension, and solid phase methods, among others, are all used to modify polymers. The melting process is the most popular among them and may be easily applied in a twin-screw extruder.

2.Polymer graft modification's second-order effects

폴리머는 그래프트 변형을 통해 극성 작용기를 추가하여 다양한 새로운 효과를 창출할 수 있으며, 여기서는 주요 효과에 대해 설명합니다.

1.Effect of flame retardants

Through grafting chemical process, flame-retardant elements or groups are added to the polymer's main chain or side chain, transforming the polymer into an intrinsic flame-retardant resin. For instance, adding boron, silicon, sulfur, metal, etc. to the resin can increase its ability to resist flame. As an illustration, the oxygen index of 1.2% silane grafted PS grew from 18.3% to 20.6%, that of 9.2% boron grafted PS from 18.3% to 25.6%, and that of 2.1% silane grafted EVOH from 21.8%. The oxygen index of 2.01% boron grafted EVOH grew from 21.8% to 33.2%, reaching a maximum of 24.8%.

2. The compatibilizer's function

To increase the resin's compatibility with other polymers, reactive functional groups are added by the chemical process of grafting. It may be used as a compatibilizer for polymer alloys, such the HDPE/PA compatibilizer, which is typically polyethylene grafted maleic anhydride.

3. A toughening agent's function

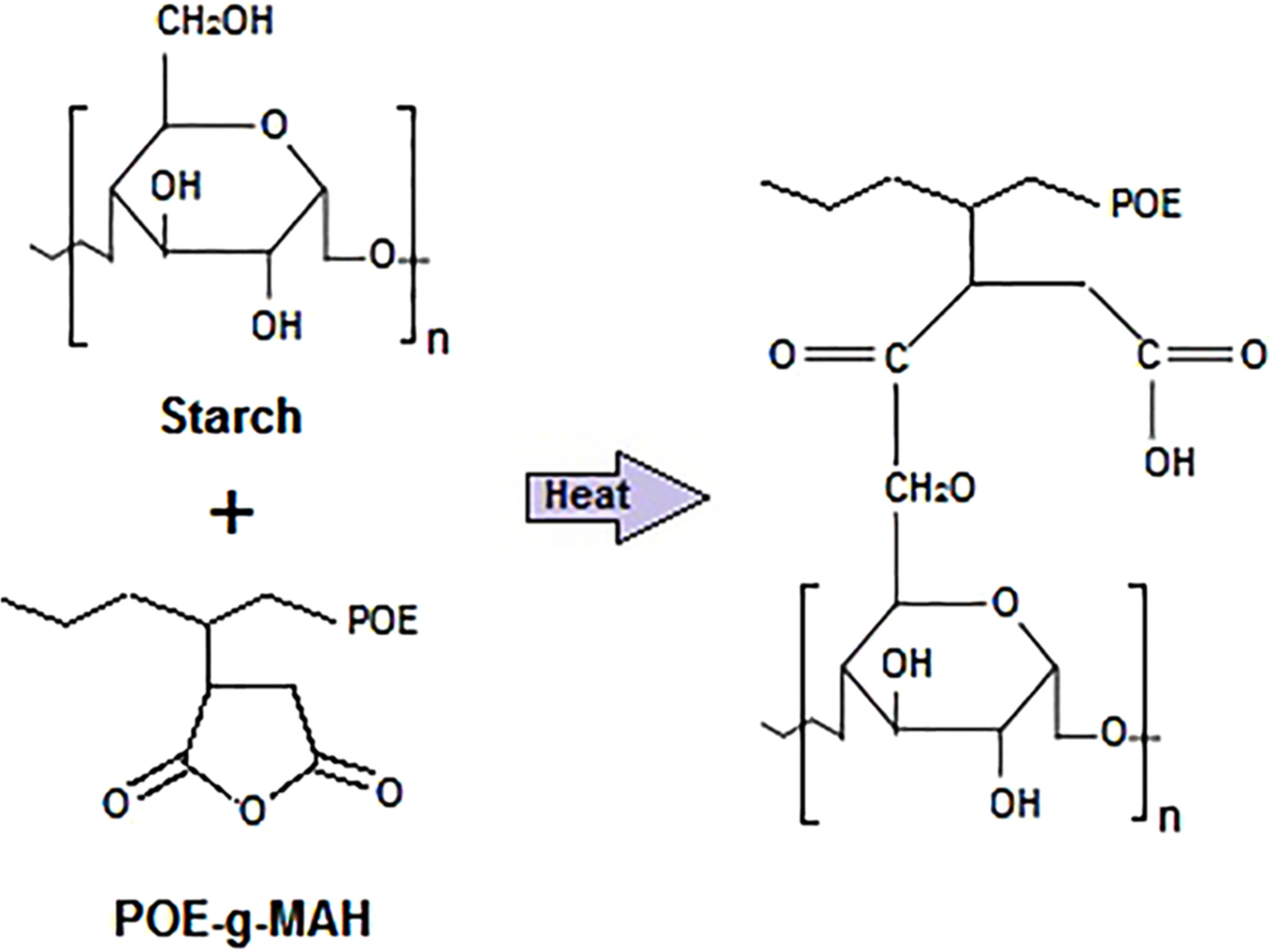

Although many elastomers have a good toughening effect, it is challenging to exert the required toughening impact due to their poor compatibility with the toughening matrix resin. This type of elastomer's compatibility with the toughening matrix resin and toughening performance may both be significantly enhanced after graft modification treatment. Because of the poor compatibility between POE and PA, pure POE, for instance, has a good toughening effect on PP but is bad for PA; nevertheless, if maleic anhydride is employed for graft modification to generatePOE-g-MAH, the rise in It becomes the ideal toughening agent for PA to assure compatibility. Another illustration is the overall toughening impact of pure SEBS on PET and PBT, which is similarly due to the two materials' poor compatibility. It is a superb toughening agent for PET and PBT if glycidyl methacrylate (GMA) is utilized to carry out graft modification to create SEBS-g-GMA.

3 Polymer graft modification formula composition

Resin, grafting monomer, initiator, and antioxidant are the major ingredients in the polymer grafting formula.

(1) Resin

The major component of grafting is resin, which is often made of PP, HDPE, LDPE, LLDPE, EVA, PS, and EPDM.

(2)graft monomer

This graft is the monomer. The unsaturated fatty acids, methylene succinic acid, formic acid Glycidyl acrylate (GMA), maleic anhydride (MAH) and its derivatives, acrylic acid (AA) and its derivatives, methacrylic acid (MMA), methylene succinic acid, butyl acrylate (BA), ethyl acrylate (EA), acrylamide (AM), vinyl silane, and unsaturated silane wait. The grafting effectiveness often decreases with the length of the grafted monomer's chain. Maleic anhydride, which has a highly reactive double bond and does not easily self-polymerize under processing conditions, is the most often utilized grafting monomer. The amount of monomer supplied is typically around 1%, however depending on the actual application needs, it may potentially be raised up to a maximum of 20%.

It is occasionally required to add a second monomer to boost grafting rate and decrease risk of adverse effects. The second monomer consists of substances like acrylamide, acrylate, and styrene. The grafting efficacy of a single monomer is particularly low for GMA grafting, necessitating the addition of a second styrene monomer and occasionally an electron donor, such as dimethylsulfoxide, dimethylacetamide, etc.

(3) The starter

The role of initiator is to initiate the reaction of grafted monomers and resins, specifically benzoyl peroxide (BPO), dicumyl peroxide (DCP), 2,3-dimethyl 2,3-diphenylbutyl Alkane (DMDPB), acrylamide (AM), 2,5-di-tert-butyl peroxy-2,5-dimethyl 3-acetylene (LPO) and 1.3-di-tert-butyl peroxyisocene, etc. The addition typically amounts to 0.1%. A novel class of initiator is DMDPB. Although its initiation efficiency is lower than that of BPO and DCP, it has the advantages of a high decomposition temperature and relatively stable free radicals, which lessen the likelihood that graft crosslinking would result in the formation of macromolecular gels. During processing, the graft does not seem gel-like or contains a little amount of gel.

The use of composite initiators has been researched recently. For instance, the grafting rate will quadruple when DCP_BPO=1:1 is utilized. For instance, the grafting result is considerably greater when utilizing DCP and BPO to double-initiate undecanoic acid grafting PP than when using it alone.

Different resins are suited for different initiators in the given selection. By contrast, when BPO is used as the initiator, only a tiny amount of degradation happens in PP, and it changes significantly with an increase in the initiator concentration. This is in contrast to DCP, which is employed as the initiator for PP and has substantial side effects and a large degree of degradation. few. In general, DCP initiator is utilized while grafting GMA monomer.

(4) Antioxidant

Antioxidants can stop grafting and degradation reactions simultaneously. It is primarily added to resins that degrade quickly, such PP and ABS. Antioxidant 1010 and other specific types are included, and the addition is roughly 0.5%. A composite grafting method that grafts two or more monomers onto one resin to create a multi-monomer graft, which has better performance, has been developed in recent years. For instance, introducing the second monomer styrene can effectively regulate the degradation of PP and increase the grafting effect of MAH or GMA when MAG or GMA is used to graft PP.