The use of a compatibilizer can significantly boost the compatibility of inorganic powder and organic resin as well as their bonding strength. It is a widely utilized degradable material modification additive in biodegradable materials and is used to make a variety of degradable goods.

01 "Molecular bridge" between the filler and matrix's adhesive contact

A chemical containing two functional groups that have differing characteristics is called a compatibilizer. The presence of two groups with various chemical characteristics is the molecule's most notable molecular trait. A group that is compatible with resins or other polymers or that experiences chemical reactions in them is an organophilic group. The other is an inorganic-philic group, which is easily chemically reactive with the surface of inorganic substances.

Compatibilizers are sometimes known as "molecular bridges" because they may enhance the interface between inorganic and organic materials. This considerably enhances a variety of composite material qualities, including tensile, thermal, and optical capabilities.

Active groups like amino groups are coupled with the compatibilizer.

The compatibilizer's unique property is its ability to react with both the matrix resin and certain groups on the surface of the filler material, creating an interfacial layer between the two. The interface layer can transmit stress, increasing the performance of the composite material and strengthening the binding between the filler material and the resin while also preventing other media from entering into the interface and improving the interface state.

Reactive compatibilizers are typically macromolecular in nature and are made of a non-polar polymer main chain with active groups (primarily irregular anhydride, hydroxyl, and epoxy groups). The active functional group of the molecule might be found either at the side chain or at the end of the molecule. It can retain good compatibility whether the macromolecular main chain is the same or different from at least one polymer matrix in the blend system.

02To enhance the general performance of materials, increase the compatibility of fillers and resins.

The compatibilizer encourages the blending of two incompatible materials to produce a stable mix by utilizing the intermolecular bonding force.It is possible to create a mix material that performs well when utilized in plastic modification.Presently, maleic anhydride is often grafted onto improved compatibilizers.Maleic anhydride monomers are more polar and exhibit greater compatibilizing properties when compared to other monomers.

By adding strong polar reactive groups, the maleic anhydride graft compatibilizer increases the material's polarity and reactivity. It is a polymer interface coupling agent, compatibilizer, and dispersion promoter that is primarily used in filling, glass fiber reinforcement, toughening, alloy compatibility, etc. It can significantly increase the compatibility of composite materials and the dispersion of fillers, improving the mechanical strength of composite materials.

The compatibilizer forms a "bridge" between the two by reacting with the polar groups on the surface of the filler and adhering to the surface of the organic material simultaneously.

A maleic anhydride-grafted compatibilizer can enhance the compatibility of organic and inorganic fillers, boost product tensile and impact strength, achieve high filling, use less resin, promote processing fluidity, and smooth out rough surfaces.

The majority of the compatibilizers have polar groups that can connect with the polar groups in the filler or undergo esterification reaction, lowering the polarity and hygroscopicity of the filler. A non-polar segment with strong compatibility with the polymer is also included in the compatibilizer. This segment serves as a "bridge" to successfully link the filler and the polymer together and enhance their interfacial bonding performance.

Introduction to the main function

The primary goal is to:

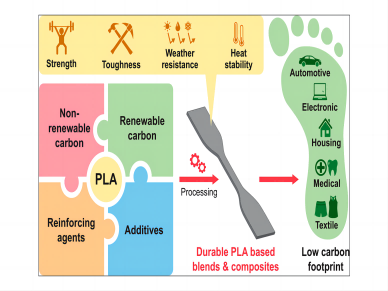

1. Increase the melt strength and thickness uniformity of PLA, PBAT, and starch blown film products.

2. Increase the bonding strength between fillers and natural fibers and PLA/PBAT

3. Increase the pigments' dispersion in PLA/PBAT

4. Raise the PLA/PBAT alloy's thermal distortion temperature 5. Boost its tensile and impact strength

6. Increase the surface rigidity of the packaging bag and straw.