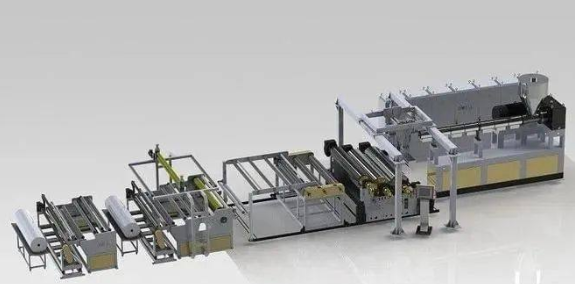

EVA photovoltaic encapsulation film production machine

The main components of the whole set of equipment consist of extruder, mould, five-roller calender, thickness gauge, winder and other equipment. The extruder screw is professionally designed according to the properties of EVA material, so that it has better plasticising properties and constant temperature performance.

The five-roller calender, the die and other important parts of the extruder use a temperature regulation system to ensure that the material is not plasticised at too low or too high a temperature, which can lead to poor plasticisation or over-plasticisation resulting in cross-linking.

It also ensures that the surface temperature of the rollers is always within the specified range, so that the film shrinkage is not greater than the specified range due to overcooling or overheating.

The winder of this machine differs from other film winders in that it has a special design. The tension of the EVA film is precisely controlled during winding to avoid too much tension leading to shrinkage outside the specified range and too little tension leading to wrinkling and uneven winding.

Ethylene vinyl acetate EVA

EVA is a copolymer of ethylene and acetic acid that is derived from petroleum. It has a wide range of uses, mainly for photovoltaic panel encapsulation, shoes and packaging etc. Today I would like to introduce its important use – photovoltaic panels encapsulation. EVA raw material used for PV panel encapsulation, we usually refer to it as PV grade EVA, with a VA content of 23%-30%.

Ethylene vinyl acetate EVA photovoltaic encapsulation film

EVA encapsulation film is a material widely used on solar panels, its main role is to silicon and glass stick together, can resist the impact of the external environment on the panel, increase power generation efficiency and improve the service life of solar panels.

Currently there are two main types of EVA encapsulation film in common use, one is EVA transparent film, the other is EVA white film.

EVA transparent film is mainly used on the sunrise side of the panel, EVA white film is mainly used on the back side of the double wave type panel.