A good nylon toughening material is one that is macroscopically compatible but microscopically incompatible.

So how do we achieve this?

POE graft maleic anhydride is the main type of nylon toughening agent, but what is the right one?

☞ POE Graft Maleic Anhydride

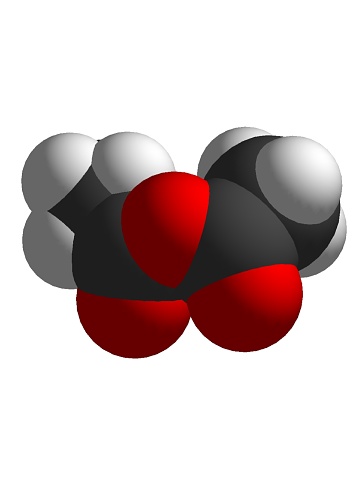

POE polyolefin elastomers are grafted with maleic anhydride, a polar group, under certain conditions, so that they are compatible with nylon, and then dispersed in nylon during the nylon toughening process, forming an island-like structure, thus playing a role in toughening and impact resistance.

The POE type of nylon toughening agent should be concerned about their two main indicators

☞ Grafting rate

Too high a grafting rate will make it too uniformly dispersed, thus failing to form an island structure, while too low a grafting rate will cause compatibility problems, such as peeling and delamination, which will obviously also fail to form a toughening effect, so a proper grafting rate of 0.3-1.0 is considered appropriate.

☞ Cross-linking

Moderate cross-linking can make it dispersed in the nylon to play a better toughening effect, but after excessive cross-linking to form a gel, the gel will not be dispersed, which is counter-productive to the nylon toughening, and will not play a good toughening effect.