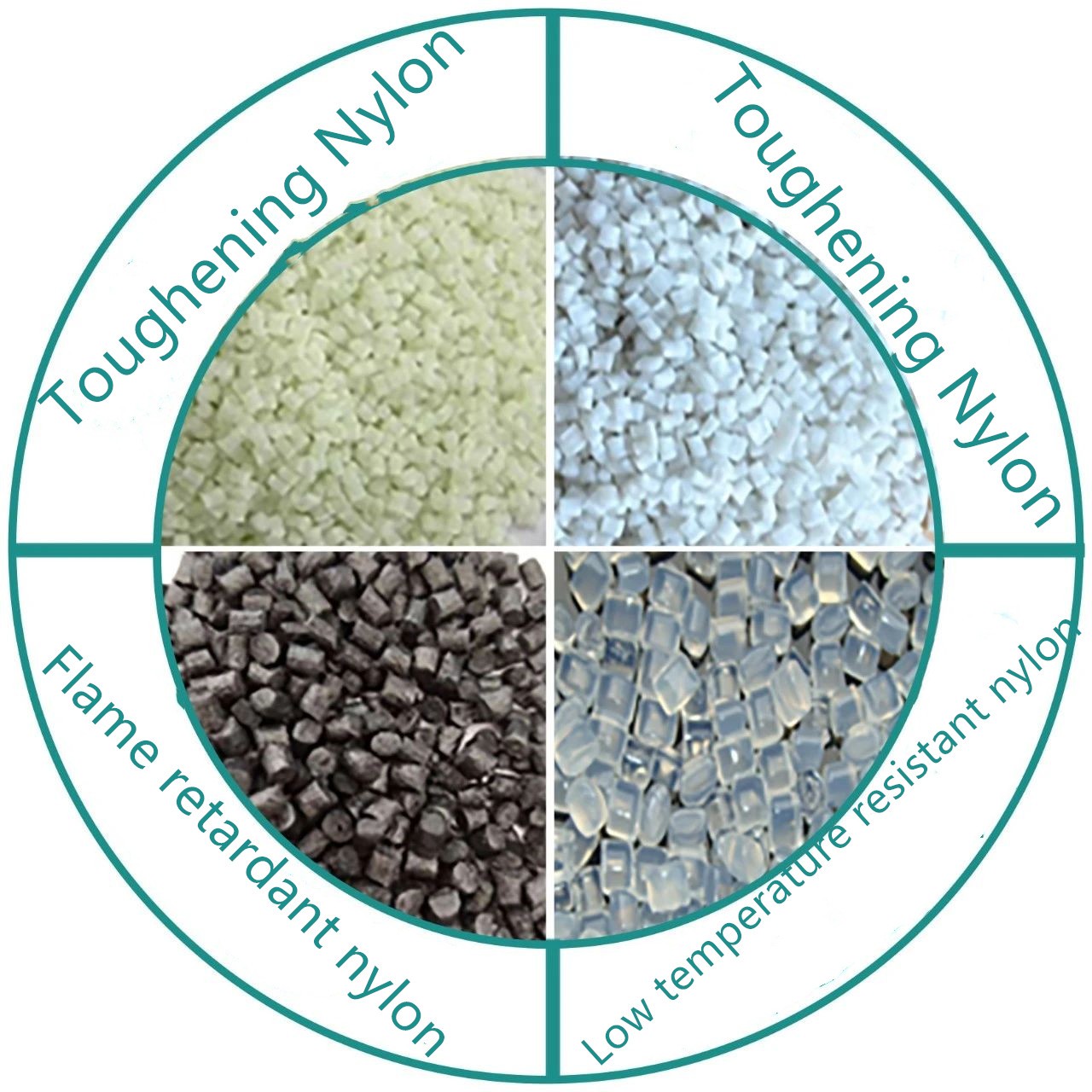

Nylon, also known as polyamide, is an important member of the top five engineering plastics. There are many modifications to nylon, such as reinforcement, flame retardant, toughening, low temperature resistance and so on.

Nylon toughening is also an important branch of nylon modification, so how to achieve nylon toughening?

By dispersing elastomers that are compatible with nylon, nylon products will eventually have better low temperature resistance and impact resistance.

It is important to emphasise two points here. Firstly, the elastomer used to toughen the nylon must be a tougher elastomer than nylon.

The second is that the elastomer must be modified. For example, grafting, so that it has a certain degree of compatibility with nylon, then this to emphasise two points, is a certain degree of compatibility, but not completely compatible.