商品説明

When used as a chemical addition for polymer modification, the Maleic Anhydride SEBS Copolymer Toughening Agent provides outstanding value and effectiveness. This toughening agent allows polymers to reach their maximum potential because of its maleic anhydride modification, compatibility with SEBS copolymers, toughening action, and compatibility with a variety of polymers.Maleic Anhydride SEBS Copolymer Toughening Agent can be added to formulations to improve toughness, durability, energy absorption efficiency, and adaptability for a range of applications in consumer goods, automotive, electronics, and packaging.

高度な設備!

先進的な生産ラインと実験試験センターを備え、製品の品質を保証する。

強力な技術力!

10人以上の経験豊富な技術研究開発スタッフが、絶え間ない技術革新を推進しています。

Typical Data of Toughening of PA6 Resin

| パフォーマンス | 単位 | PA6 | PA6+15%W1G | PA6+20%W1G |

| 引張強さ | MPa | 60 | 51 | 45 |

| 曲げ強度 | MPa | 90 | 73 | 67 |

| Lzod notched impact strength | J/m | 80 | 650 | 820 |

It can be seen from the above table that W1G has a good effect in nylon toughening and can greatly improve the toughness of nylon.

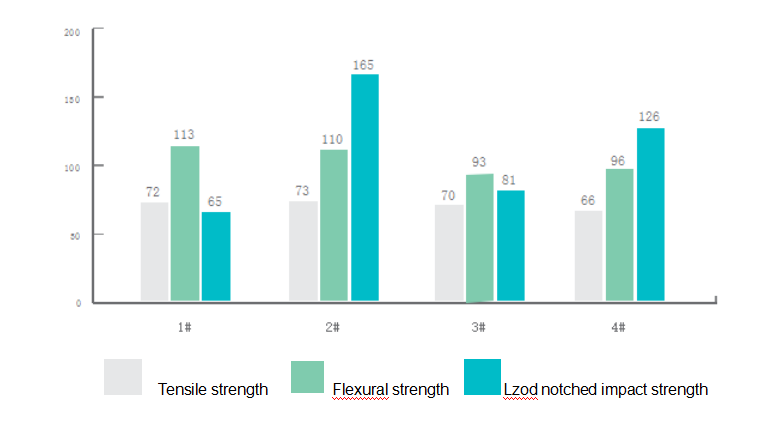

PA/PPO合金の代表的なデータ

| フォーミュラ | 1#(%) | 2#(%) | 3#(%) | 4#(%) |

| PA6-3280 | 25 | ⸺ | 30 | 60 |

| PPA66-EPR27 | 65 | ⸺ | ⸺ | |

| PPO | 60 | 20 | 50 | 45 |

| CS-1(PP0コンパチビライザー) | 10 | 10 | 15 | 15 |

| W1G(強化剤) | 5 | 5 | 5 | 5 |

| シリコーンパウダー | 0.5 | 0.5 | ⸺ | ⸺ |

| ペット | ⸺ | ⸺ | 0.3 | 0.3 |

From the above table, it can be easily seen that the PW1G/PO alloy can improve the flexibility of the product on PA, and the product is easier to carry forward.

特徴

| テスト項目 | テストデータ | 試験方法 |

| 密度 | 0.91 g/cm³ | ASTM D792 ISO 1183 |

| メルティング・インデックス | 2-9 (190℃,50kg) g/10min | ASTM D1238 ISO 1133 |

| 移植率 | ミディアム | 酸塩基滴定 |

| 外観 | 白色または淡黄色 粒状 |

W1G is a maleic anhydride grafted polymer. SEBS elastomer is used as the base material. The product has good fluidity, good temperature resistance and aging resistance.

- Maleic Anhydride Modification: To strengthen its chemical linkages with the polymer matrix, maleic anhydride is added to the toughening agent. By improving the toughening agent and polymer’s compatibility and interfacial adhesion, this change allows for more uniform dispersion and better mechanical characteristics.

- The toughening agent is formulated using the styrene-ethylene/butylene-styrene (SEBS) copolymer, which has remarkable compatibility with an array of polymer matrices. It guarantees even dispersion and effective mixing throughout the polymer, which enhances its toughness and resistance to impacts.

- Toughening Effect: Polymers’ toughness and impact resistance are greatly increased by the Maleic Anhydride SEBS Copolymer Toughening Agent. The process of energy absorption and dispersion during deformation lessens the likelihood of crack propagation and improves the material’s resistance to impact and dynamic stress.

- Compatibility with a Wide Range of Polymers: The toughening agent shows compatibility with engineering plastics, ABS, polypropylene, polyethylene, and polystyrene, among other polymer matrices. It provides flexibility and adaptability, enabling the creation of unique solutions to satisfy certain performance standards.

メリット

Increased Toughness: Polymers become more resilient when the Maleic Anhydride SEBS Copolymer Toughening Agent is included. It produces materials that can endure demanding applications and difficult environments by improving the impact resistance, tensile strength, and elongation at break.

Increased Durability: Polymer products have increased durability thanks to the toughening ingredient. It guarantees the modified polymers’ long-term performance and dependability by lowering the chance of cracking, delamination, and deformation.

Effective Energy Absorption: By effectively absorbing and distributing energy during deformation, the toughening agent lowers the chance of stress concentration and crack propagation. It improves the material’s resistance to impact and dynamic loading, making it appropriate for uses where strong impact resistance is needed.

Versatile Uses: The Maleic Anhydride SEBS Copolymer Toughening Agent is used in a wide range of fields and sectors, such as consumer products, automotive, electronics, and packaging. Because of its adaptability, various polymers can be altered to satisfy particular performance needs.

当社の強み

グローバル・サプライチェーン

健全な保管・物流サプライチェーンシステム

テクニカルサポート

アフターサービス

フォーカス - アチーブメント - エクセレンス!

カスタマイズ製品

研究開発に注力

グローバルサービス

コエース認証!

ISO9001:2015認証

ISO14001:2015認証

EUのREACH登録

韓国K-REACH事前登録

企業の利点!

国内外でのレイアウト、ミキシングに最適

国内マーケティング・レイアウト

海外マーケティング・レイアウト

申し込み

1. Elastomer modification such as TPE/TPR can be used for encapsulating nylon, etc.

2. Engineering plastics toughening agent compatibilizer

3.改質アスファルト

4. Adhesive