Application of Polyolefin Grafted Maleic Anhydride as Compatibilizer

Polyolefins (PE, PP, EPDM, EPR, EVA, etc.) have poor compatibility with other materials, such as polar polymers, inorganic fillers, etc., due to their non-polarity and crystallinity, making it impossible to prepare useful blended materials. The addition of pre-made or in-situ compatibilizers enables otherwise incompatible polymers to form blends with unique properties not found in either component. As a kind of surfactant, compatibilizer can reduce the surface tension and improve the interfacial cohesion between the dispersed phase and the continuous phase in the blend.

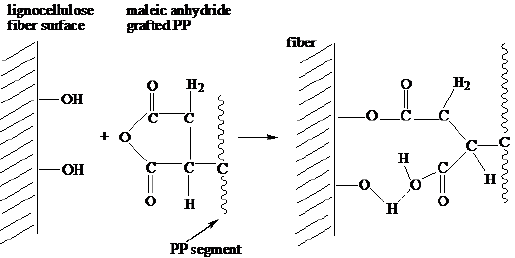

In order to expand the application range of polyolefins and develop more valuable new materials, functionalized polyolefins as compatibilizers have always been an important field in scientific research and industrial production. To date, maleic anhydride-grafted polyolefins (PO-g-MAH) are the most important functionalized polyolefins due to their cheapness, high activity, and good processability. It has a wide range of applications in polymer blends, polymer/inorganic fillers, polymer/organic fibers, composite reinforcements and adhesives.

There are many methods for grafting maleic anhydride to polyolefin, mainly including solution method, melting method, radiation method and solid phase method. But the most important method is the melt method, the so-called “reactive extrusion method”. The mechanism of melt grafting is complex and accompanied by serious side reactions, manifested as crosslinking of polyethylene grafting reaction, degradation of polypropylene, and simultaneous occurrence of two side reactions in ethylene-propylene rubber. Adding some electron donor compounds containing N, P, and S atoms, such as dimethylformamide (DMF) and dimethylacetamide (DMAC), can inhibit these side reactions such as crosslinking and degradation.

Melt grafting

It can be performed in a single-screw extruder, a twin-screw extruder or a Brabender rheometer. Mix polyolefin, MAH monomer, initiator and other additives uniformly with the help of a small amount of dispersant, and then feed the mixture into the hopper of the extruder for melt extrusion. There are many factors affecting the reaction of polyolefin-grafted maleic anhydride, mainly including the type and concentration of the initiator, the mass concentration of the monomer, the type and concentration of the additive, the reaction temperature and the reaction time, etc. When the concentration of initiator DCP increases, the grafting rate increases accordingly, but the amount of DCP is too much, accompanied by cross-linking reaction; when DCP is fixed, the grafting rate shows an upward trend with the increase of the amount of MAH, but when the amount of MAH continues to increase The effect on the grafting rate becomes smaller; when the reaction temperature is low, the decomposition concentration of DCP is high, but it is also conducive to the occurrence of side reactions, thus consuming free radicals, so that the free radicals are not significantly improved; the melting reaction time (ie extruder The rotation speed of the screw) has a great influence on the grafting rate. When the screw speed is too fast, the material stays in the barrel for a short time, the reaction is insufficient, and the grafting rate decreases. When the screw speed is too slow, the shear force is too small, resulting in uneven dispersion of the initiator, and the material residence time is too long, which will cause severe crosslinking and reduce the grafting rate. Based on the above results, in the LDPE grafting process, the dosage of DCP is 0.08~0.1 part, the dosage of MAH is 4~5 parts, the reaction temperature is 160~170℃, and the screw speed is 40~45r/min. During the PP grafting process, the dosage of DCP is 0.2~0.4 parts, the dosage of MAH is 5~7 parts, the reaction temperature is 175~180℃, and the screw speed is 30~45r/min.

Judgment of High Quality Maleic Anhydride Graft

When judging high-quality maleic anhydride grafts, several key factors that need to be considered include: odor, grafting rate, yellowing index, and whether ungrafted maleic anhydride is separated in the later stage of the reaction. It should be noted that in the grafting reaction, the grafting rate is generally low, because a lot of added maleic anhydride is not grafted to the main chain. Most of the ungrafted maleic anhydride exists in the reaction system in the form of polymaleic anhydride. Therefore, if the product after the grafting reaction is not separated, the final product will be a mixture containing grafts and polymaleic anhydride. . That is to say, the grafting ratio of maleic anhydride tested before and after separation has a large deviation.

Application:

The most successful application of maleic anhydride grafted polyolefin is in the application of polyamide (PA) blends. As an engineering plastic with excellent performance, PA is widely used. However, there are also disadvantages such as poor low temperature and dry impact strength, high water absorption, and low notched impact strength. Due to the strong polarity of PA, it is incompatible with non-polar polyolefin resins, making the research and development of polyolefin modified PA very slow. Until the research of reactive compatibilization technology was successful, the blends of polyolefin modified PA appeared in large quantities, and the reactive compatibilizer used was mainly MAH grafted polyolefin.

When polyolefin-grafted maleic anhydride is melt-blended with PA, the active anhydride group grafted on the PO main chain reacts with the amino group at the end of the PA molecule, initially forming an amide bond, and forming an imide bond after ring closure to form PO-g-PA graft copolymer. In this way, the graft copolymer located on the phase interface strengthens the cohesive force between the phase interfaces through covalent bonds, expands the distribution range of the dispersed phase in the continuous phase, and significantly improves the performance of the copolymer.

The impact strength of PE and PP grafted PA blends increased with the increase ofPE-g-MAHcontent. When the mass fraction of PE-g-MAH reaches 30%, the impact strength reaches the maximum, and the brittle-ductile transition temperature drops by more than 50°C. In the PA6/PE-g-MAH/PE ternary system, when the PA content is fixed, increasing the content of PE-g-MAH and increasing the molecular weight of PA6 can significantly improve the impact strength of the blend.

【Polyolefin Elastomer Graft MAH Toughened Nylon】

MAH-toughened nylon grafted with polyolefin elastomers has achieved great commercial success. The MAH on the grafted polyolefin elastomer reacts with PA to form a graft copolymer in situ, which greatly improves the compatibility between the elastomer and PA and achieves a satisfactory toughening effect. According to the experiment, four kinds of polyolefin elastomer grafted MAH systems are EPDM, EPR, SEBS and ultra-low density polyethylene (ULDPE). The effects of these four elastomers grafted with MA to toughen PA6 are as follows: EPDM-g-MAH>EPR-g-MAH>SEBS-g-MAH>ULDPE-g-MAH. The ULDPE-g-MAH system has the narrowest particle size distribution and the smallest average particle size, but its toughening effect is the worst. In addition, POE grafted maleic anhydride can also modify PA.

[Application of polyolefin grafted MAH in modified polyester (PBT, PET) blends]

Since its commercialization in 1970, butylene terephthalate (PBT) has become the fastest growing type of injection molding resin due to its excellent performance, high crystallization rate and crystallization rate, and moderate price. Because of its chemical resistance, thermal stability, water stability, good melt fluidity and electrical properties, it is widely used in electrical, automotive, construction and other industries. However, poor impact strength limits the further application of PBT. Much research has been done to improve the impact strength of PBE, typically with rubber or impact plastic modification.

If PBT and linear low density polyethylene (LLDPE) are combined to toughen PBT. Due to their incompatibility, ethylene-vinyl acetate copolymer (EVA) grafted MAH was added as a compatibilizer. Through the reaction of MAH grafted on EVA and the terminal hydroxyl group of PBT, a graft copolymer is formed on the two-phase interface, which increases the interfacial adhesion of the two phases. After adding EVA-g-MAH, the impact strength of PBT/LLDPE (70/30) blends has been greatly improved, while not losing a lot of flexural strength and tensile strength, but when the mass fraction is 1~ When 3% EVA-g-MAH, the tensile strength and flexural strength reached the maximum. Compared with PBT/LLDPE adding ungrafted EVA, the mechanical properties of EVA-g-MAH system are more obvious. As the amount of EVA-g-MAH increased, the viscosity of the system also increased, which also confirmed that the grafting reaction occurred on the phase interface to increase the adhesion of the two phases. The toughened PBT copolymer can also be obtained by melt blending EPR-g-MAH and PBT. The MAH grafted on EPR reacted with the terminal hydroxyl groups of PBT to generate (EPR-g-MAH)-g-PBT grafts in situ. The graft acts like a surfactant, which reduces the interfacial tension, reduces the size of the rubber particles, increases the two-phase adhesion, and improves the toughness.

Polyethylene terephthalate (PET) is widely used in packaging (mainly bottles), electronics and other industries. Blends of PET and other polymers, especially polyolefins, have interesting mechanical and barrier properties, as well as good processability. Moreover, in today’s ever-increasing awareness of environmental protection, the performance of this blend that can be reused without sorting is even more valuable. Because PET and polyolefin graft MAH also achieved good results in compatibilizing PET/polyolefin system.

[Application of polyolefin grafted MAH in modified TPU blends]

Due to the different polarity and high tension at the interface, thermoplastic polyurethane (TPU) and PE are incompatible, and the mechanical properties of the blends are even lower than those of the individual components. Using PE-g-MAH as a compatibilizer increases the polarity of PE. At the same time, during the melt blending process, the urethane bond on TPU is dissociated by heat, reacts with MAH to form isocyanate, and then the isocyanate reacts with each other , forming a graft copolymer in situ at the interface, which increases the compatibility between PE and TPU and improves the mechanical properties of the blend.