Reinforced nylon, monomer casting nylon (MC nylon), reaction injection molding (RIM) nylon, aromatic nylon, transparent nylon, high impact (super strong) nylon, electroplated nylon, conductive nylon, flame retardant nylon, etc. are only a few of the many modified variants of nylon.

Let’s discuss a few of the more prevalent modified nylons.

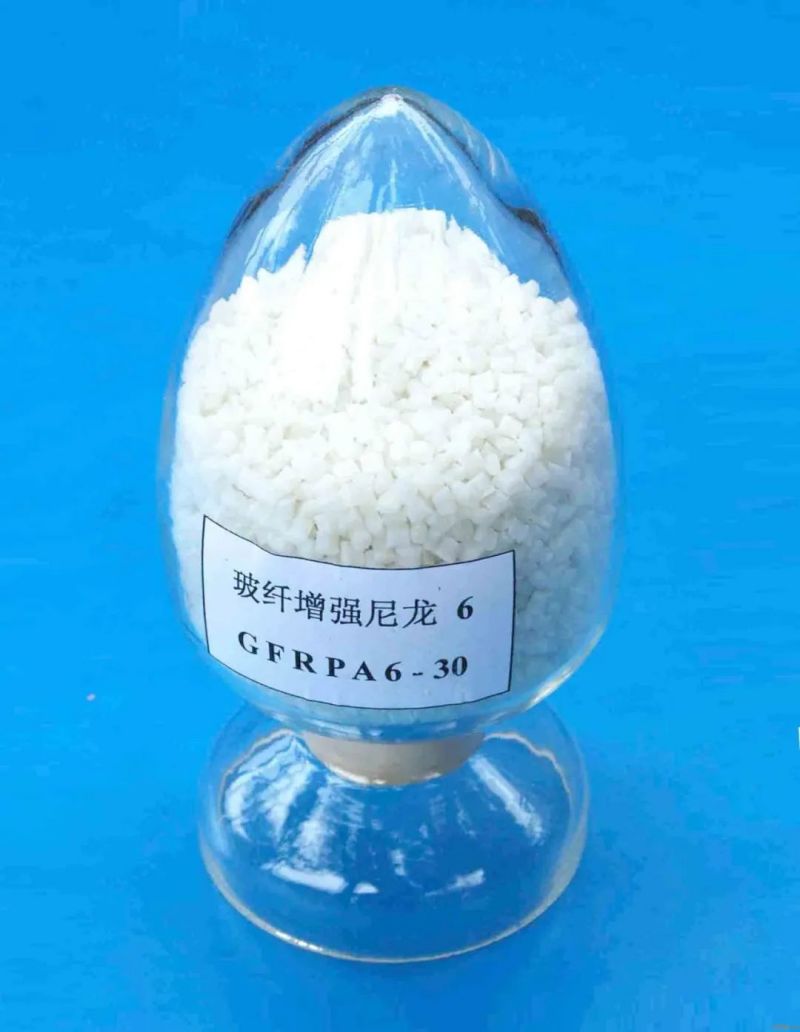

1 bolstered nylon

Strength and modulus are greater with nylon rinforzato. The tensile strength and bending strength of nylon are substantially increased with the inclusion of glass fiber or carbon fiber, and the impact strength is complicated. The addition of a toughening agent increases the toughness of nylon. Significant improvement; 30% to 35% of glass fiber and 8% to 12% of a toughening agent are added, giving reinforced nylon its full range of mechanical qualities.

2 thorny nylon

Numerous engineering polymers are unable to function in particular application environments. For instance, many materials are either too brittle or not sturdy enough. By incorporating tougher components or extremely fine inorganic compounds, nylon’s toughness and low-temperature performance can be improved.

Toughener: An ingredient added to the resin to increase the plastic’s impact strength and elongation while lowering its brittleness after hardening.

3 nylon that doesn’t burn

Materials must be flame retardant in many businesses, including those that manufacture electrical products and vehicles, however many plastic raw materials have poor flame retardancy. Flame retardants can now be added to materials to increase their flame resistance.

The majority of these functional additives are compounds of the VA (phosphorus), VIIA (bromine, chlorine), and IIIA (antimony, aluminum) group elements. They are also known as flame retardants, fire retardants, or fireproofing agents.

Oltre a essere ritardanti di fiamma, i composti di molibdeno, stagno e ferro che hanno proprietà di soppressione dei fumi sono per lo più appropriati per le plastiche che necessitano di ritardare la fiamma per ritardare o prevenire la combustione delle plastiche, in particolare quelle polimeriche. La combustione richiede più tempo, è autoestinguente e difficile da accendere.

4 climatically resilient nylon

Plastics become brittle at low temperatures because of their innate low-temperature brittleness. Cold resistance is thus typically necessary for many plastic items utilized in low-temperature situations.

La resistenza agli agenti atmosferici è un termine utilizzato per descrivere un gruppo di eventi di invecchiamento che si verificano su articoli in plastica nel corso del tempo a seguito dell'esposizione al sole, alle fluttuazioni di temperatura, al vento, alla pioggia e ad altri fattori ambientali. Questi fenomeni di invecchiamento comprendono lo scolorimento, la decolorazione, la fessurazione, la polverizzazione e la riduzione della resistenza. Una delle cause principali dell'invecchiamento della plastica è l'esposizione ai raggi UV.

5 alloy nylon

Per preparare due o più materiali in un nuovo materiale con elevate prestazioni, funzionalità e specializzazione - per fondere due materiali o per aumentare le prestazioni di uno - utilizziamo tecniche di miscelazione fisica, innesto chimico e copolimerizzazione. funzione delle caratteristiche del materiale. Riduce le spese, potenziando o migliorando le prestazioni dei polimeri attuali.

The production technique for general-purpose plastic alloys, such PA, PVC, PE, PP, and PS alloys, has mostly been mastered.

Engineering plastic alloys are mixes of engineering plastics (resins), mostly based on engineering plastics like polyoxymethylene (PA), polypropylene (PPO), polytetrafluoroethylene (PTFE), and ABS resin-modified sex products.

6 reinforced nylon that is robust

It is primarily classified into modified engineering plastics with glass fiber reinforcement, toughened and weather-resistant nylon special materials, and other items.

This new polypropylene material has the qualities of engineering plastics and is weather-resistant and hardened. It benefits from high stiffness, minimal molding shrinkage, superior low-temperature toughness, and great weather resistance.

It is mostly employed in outdoor settings where resistance to weather and UV radiation is necessary. Companies that manufacture appliances for the home and car parts are its two primary consumer categories.