The versatility and superior performance of PE-g-MAH (Polyethylene-grafted-Maleic Anhydride) has revolutionised the possibilities of polyethylene (PE) products. For companies looking for improved performance and sustainability, PE-g-MAH presents a compelling option because to its broad application range, many functionalities, durability, and environmental advantages. In this article, we explore the numerous uses of PE-g-MAH and throw light on the several grafting techniques that are employed, highlighting their benefits and effective usage in industrial production.

Wide Application Range: A wide range of sectors, including the automotive, packaging, building, and consumer products, use PE-g-MAH. It is a crucial addition to the production of pipes, packaging materials, pipes, and durable consumer items because of its capacity to improve adhesion, compatibility, and processability. Due to PE-g-MAH's adaptability, it can satisfy the various demands of many industries, making it a top choice for boosting product performance.

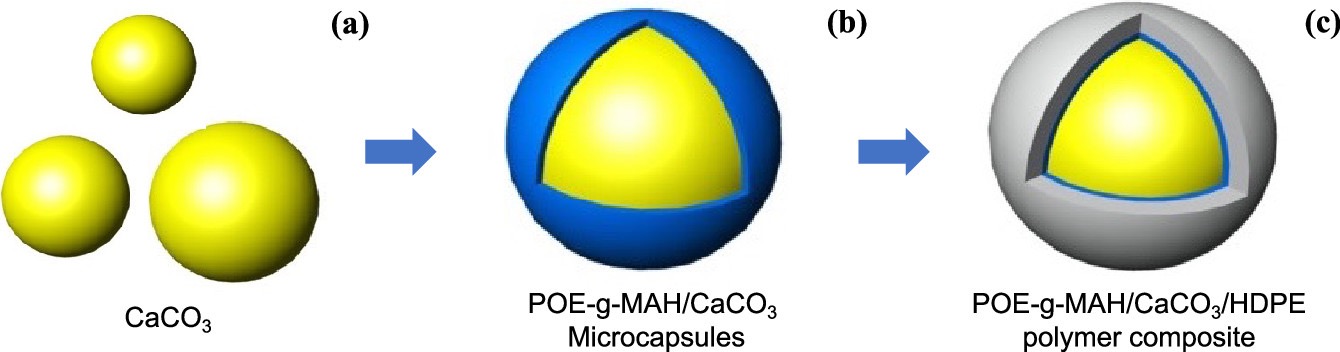

Multiple Functions and Durability: PE-g-MAH demonstrates outstanding multifunctionality when incorporated into polyethylene, as well as durability. It considerably enhances adhesion to other materials, such as metals or polar surfaces, by the grafting of maleic anhydride. Strong adhesion between plastic and metal components is essential in the automobile sector, therefore this trait is very beneficial. Furthermore, PE-g-MAH improves mechanical strength, impact resistance, and thermal stability, assuring the end product's durability and lifetime.

Environmental Protection: In a time when sustainability is a top priority, PE-g-MAH helps to safeguard the environment. It minimises waste by improving the qualities and durability of polyethylene goods, which decreases the need for frequent replacements. Additionally, adding maleic anhydride to polyethylene can make it more recyclable, enabling more effective recycling procedures. PE-g-MAH's eco-friendliness is in line with the rising need for environmentally friendly production methods.

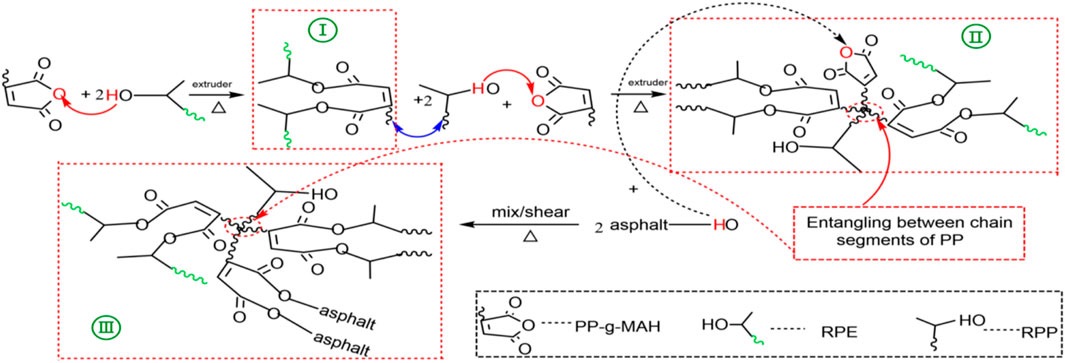

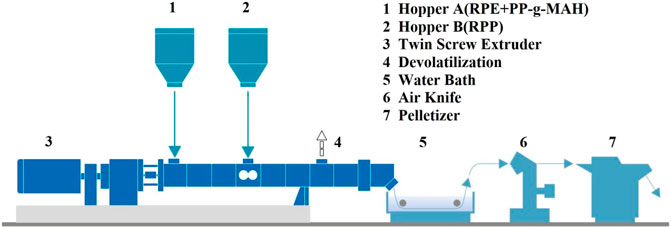

Various Grafting Methods: Maleic anhydride is grafted onto PE using a number of different techniques, including solution, melting, solid-phase, solid-phase mechanochemical, photografting, and suspension procedures. These techniques are adaptable and meet various application needs. For instance, the solution approach is appropriate for large-scale production due to its quick reaction time and continuous operation. The solid-phase mechanochemical approach uses less energy and reaction time. Based on their unique production requirements, manufacturers may choose the best grafting technique, maximising productivity and quality.

Successful Industrial Implementation:PE-g-MAH has been successfully incorporated into industrial production due to its benefits, including its broad application spectrum, numerous functions, and durability. Automotive and packaging industries have both taken use of PE-g-MAH's capabilities to improve product performance and provide desired results. These productive applications attest to the efficiency and dependability of PE-g-MAH in actual industrial settings.

Successful Industrial Implementation: PE-g-MAH has been successfully incorporated into industrial production due to its benefits, including its broad application spectrum, numerous functions, and durability. Automotive and packaging industries have both taken use of PE-g-MAH's capabilities to improve product performance and provide desired results. These productive applications attest to the efficiency and dependability of PE-g-MAH in actual industrial settings.