POE plastics are thermoplastic elastomers that in-situ polymerize ethylene and octene using metallocene catalysts.

The primary objective of POE

POE has the dual qualities of plastic and rubber and is used as a thermoplastic elastomer material.

It also has outstanding mechanical capabilities and low temperature performance. Additionally, POE has good thermal oxygen aging resistance and UV light aging resistance thanks to the saturated molecular chain structure, making it suitable for usage as an elastomer right away.

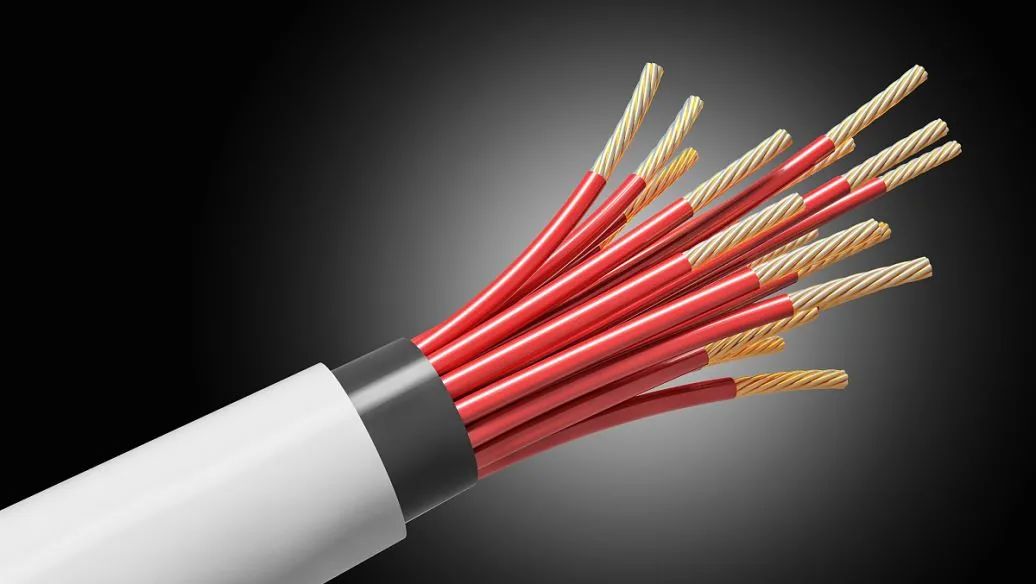

cables and wires, protective sleeves are the main applications.

used as a foaming agent

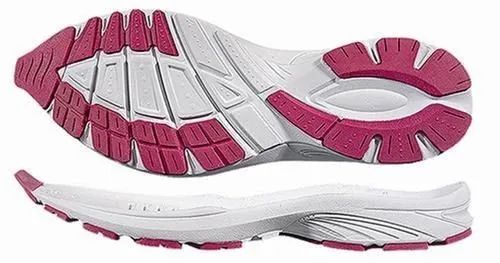

Another crucial POE application area is the creation of foamed materials. High tensile and tear strength, superior elasticity, and wear resistance are all characteristics of POE foamed materials.

Applications include the microporous bottom and sponge midsole of modern sports shoes, automobile seat cushions, mouse pads, and bag inside.

used to provide toughness

POE is frequently used to treat non-polar polyolefins because it is a non-polar saturated polyolefin copolymer, has high compatibility with general-purpose polymers like polyethylene and polypropylene (PP), and is available in granular form. Most of them are employed in the PP toughening system.

(1) PE toughening adjustment

Research on POE in polyolefin resin blending systems is mostly focused on PP/POE systems both domestically and internationally, although in recent years, research on PE/POE systems has started to pick up. Excellent compatibility with PE allows POE to provide PE matrix resins of different densities significant flexibility, particularly at low temperatures, enhancing PE’s toughness and impact resistance. The modification of PE by POE now encompasses a wide range of industries, including cable sheathing, wood-plastic composites, blown film, hollow blow molding, rotational molding, and spinning.

modified high-density polyethylene (HDPE) fiber.

About 60% of the raw material composition of fishing gear goods is made up of HDPE fiber. It is now the most popular type of synthetic fiber used in fishing gear. The breaking strength and nodulation strength of HDPE fiber are severely required at the knotting section when it is used to manufacture fishing nets. PE fiber must be repeatedly exposed to high-power thermal stretching throughout the production process to achieve the required tensile breaking strength. High heat is used to stretch HDPE fiber, increasing the crystallinity and molecular orientation while decreasing the fiber’s brittleness, which in turn reduces the strength of the nodular portion of the PE fiber.

(2) Modification of PP toughening

In PP processing, POE and EPDM are frequently employed for toughening modification to fulfill diverse functionalities, with POE modification having the greatest results. Given that POE and PP have similar viscosities and greater compatibility as a result, POE disperses more evenly in PP, assuring higher yield strength, a higher Young’s modulus, and smooth processing while toughening fluidity. The continuous phase “sea” phase in the POE/PP mix system is PP, while the scattered phase “island” phase is POE. This consistent “sea-island” arrangement can significantly increase the impact strength of PP at both normal and low temperatures.

(3) PA modification for toughening

Due to its superior solvent resistance, low coefficient of friction, and outstanding tensile and stiffness qualities, polyamide (PA) is often utilized. However, due to its notch sensitivity, it has a very low notched impact strength. As a result, it is typically mixed with an elastomer to lessen this notch sensitivity, increase the material’s impact strength in a dry condition, and decrease moisture absorption. By graft-copolymerizing POE with maleic anhydride (MAH) and utilizing the resulting compound in polyamide 6 (PA6), PA6/POE/POE-g-MAH may be created. In order to modify PA6 to make it more durable, the compatibilizer maleic anhydride-styrene (SMA) grafted ethylene-octene copolymer (POE-g-SMA) can also be made.

Thermoplastic Elastomers That Are Dynamically Vulcanized

The secret to POE’s outstanding performance is dynamic vulcanization, which may compensate for POE’s weaknesses in low temperature resistance and substantial permanent deformation. When rubber and resin are melted and combined, under the intense shear force of dynamic vulcanization, the rubber phase is vulcanized and cross-linked, and the resulting POE has a sea-island structure under a microscope. The resin phase is the continuous phase (sea phase), while the rubber phase is the discrete phase. This structure can make POE both extremely elastic and thermoplastic as a dispersed phase (island phase).