Basic introduction

An auxiliary agent that encourages the blending of two incompatible polymers to create a stable blend is referred to as a compatibilizer, sometimes known as a compatibilizer. It is a polymer compatibilization agent in this context.

An auxiliary agent that encourages the blending of two incompatible polymers to create a stable blend is referred to as a compatibilizer, sometimes known as a compatibilizer. It is a polymer compatibilization agent in this context.

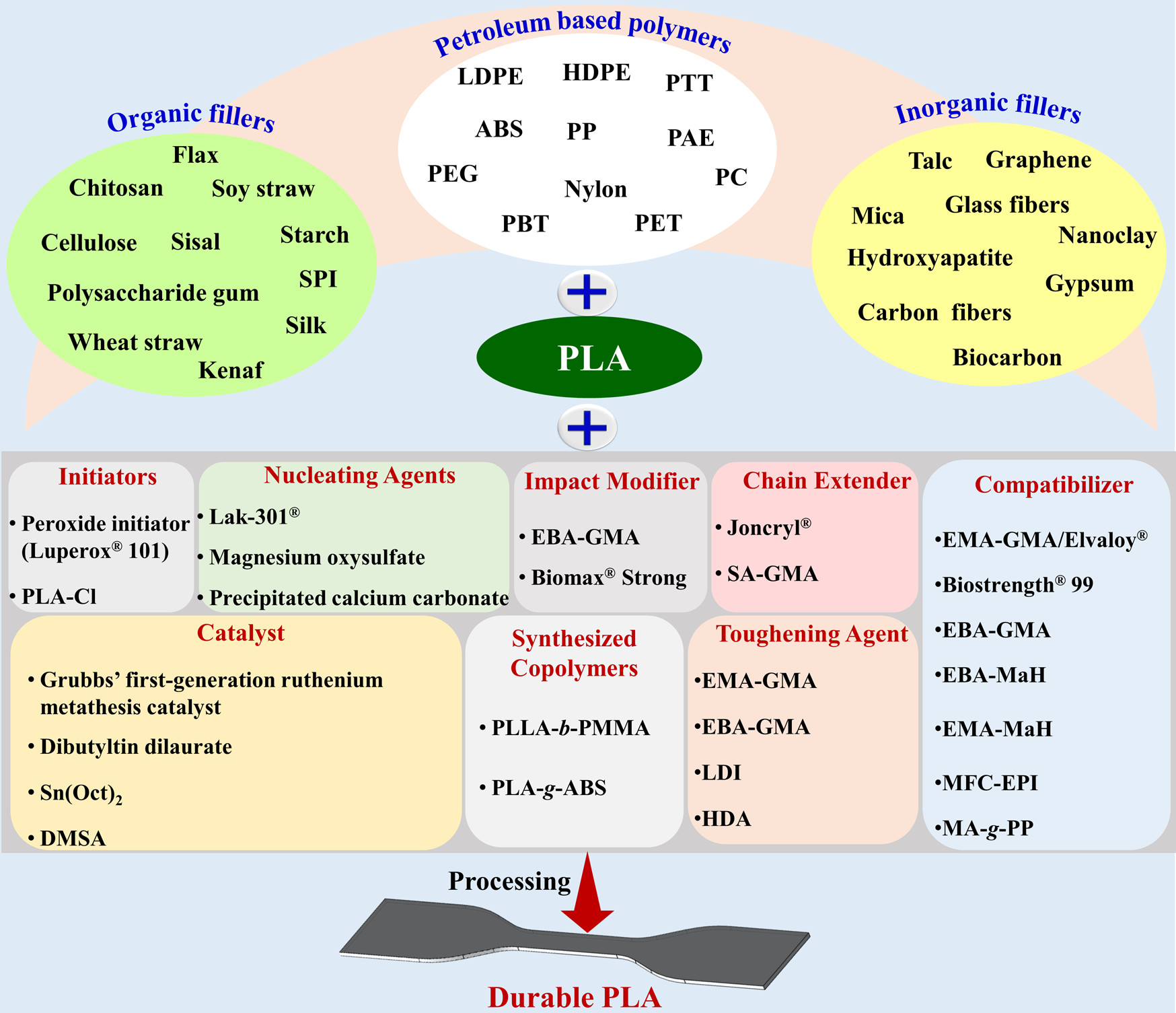

In plastic modification, substances such as PE-g-ST, PP-g-ST, ABS-g-MAH, PE-g-MAH, PP-g-MAH, etc. are used to create blended materials with high performance.

Presently, maleic anhydride is often grafted onto improved compatibilizers. Maleic anhydride monomer has more polarity and a superior compatibilization impact when compared to other monomers.

By adding strong polar reactive groups, the maleic anhydride grafted compatibilizer increases the material’s polarity and reactivity. It is a kind of dispersion accelerator, compatibilizer, and polymer interfacial coupling agent. It is mostly used as a halogen-free filler, to strengthen glass fiber, to toughen, to bind metal, to determine alloy compatibility, etc. It can significantly increase filler dispersion and composite material compatibility, increasing the mechanical strength of the latter.

A compatibilizer with maleic anhydride grafts can boost the compatibility of organic and inorganic fillers, raise product tensile and impact strength, achieve high filling, use less resin, improve processing rheology, and smoothen surfaces.

Variety of applications

(1) Filled with materials such as glass fiber, nylon, talcum powder, titanium dioxide, barium sulfate, calcium carbonate, and magnesium hydroxide.

(2) Agente indurente per PET, PBT e PA.

(3) PP/PA, PC/ABS, PC/PBT, ABS/PBT, and PS/PBT alloys may be modified and made tougher using EMA, PTW, and GMA alloy compatibilizers.

For PA, PET, PBT and their alloy materials, EMA, PTW, and GMA are employed as compatibilizers and tougheners.

EAA is used to make materials like PE, PP, and their modified versions more compatible and durable.

For polyolefin low-smoke, halogen-free, and flame-retardant cable materials, EEA and EBA are employed as compatibilizers to increase the quantity of inorganic compounds added, enhance tensile strength, and elongation.

EEA and EBA are used to modify alloys like PS/PP, ABS/PC, ABS/PA, PS/PE, etc. in order to increase the product’s toughness, compatibility, and other general features.

ST-5 is utilized for polypropylene degrading masterbatch, color masterbatch, and flame retardant masterbatch.

Aluminum-plastic composite, iron-plastic composite, polyolefin/nylon system, filler masterbatch, color masterbatch, flame retardant masterbatch, and polyethylene wood plastic are all compatible with ST-6.

Silk, polyethylene filler masterbatch, color masterbatch, flame-retardant masterbatch, low-smoke, halogen-free flame-retardant cable materials, and aluminum-plastic composite polyethylene film are all made with ST-7.

ST-8 is utilized to make alloys like AS/PP, ABS/PC, ABS/PE, ABS/PA, and ABS/PET compatible.

ST-9 is employed as a strengthened, flame-resistant ABS/PA, PC/ABS, and ABS/PP alloy compatibilizer.

Applicazione

(1) Used in relation to plastic alloy

Compatibility technology is primarily being developed for polymer material alloys. A multi-phase, multi-component system known as a polymer alloy is created by mixing two or more polymer materials with various characteristics and using the appropriate compatibilization processes. The compatibilizer is a crucial component in the creation of these polymer alloys as well as their mixing and modification. The tiny phase structure of the alloy technology is extremely well adjusted and controlled by the compatibilizer, allowing the blend material to attain excellent performance and functional effects. In PP/PE, PP/PA, PA/PS, PA/ABS, ABS/PC, PBT/PA, PET/PA, PP/POE, PE/EPDM, TPE/PU, and other alloys, compatibilizers are often employed.

(2) Applied to polymer modification

Since the compatibilizer serves as a “bridge” between non-polar and polar polymers by acting as an active free radical molecular carboxyl group, it is modified into a polar modified polymer before being combined with the polar polymer Compound blending, where the reaction between the two produces a good modified blending effect.

(3) Used for recycling discarded plastics

A better and more practical method for “comprehensive utilization of waste” and for addressing the issue of “white pollution” is to recycle discarded plastics using compatibilizers to create new plastic alloys or new modified plastics, which has significant social and business advantages. There are other examples from other nations. For instance, the Dutch National Mining Company’s BENNET compatibilizer is a unique compatibilizer for recycling waste plastics. Blending and regeneration of engineering plastics and olefin scraps, addition of 5%–10% compatibilizer as the interface layer between the sea phase or island phase, exertion of the compatibilizer’s bonding force, and preparation Turn into a new plastic alloy or modified plastic.

(4)Used in the fusion of polymers and fillers

Also known as a macromolecular coupling agent, compatibilizer. The compatibilizer has great coupling efficiency between the polymer and the filler and may be utilized for PE/CaCO3, PE/talcum powder, PA/GF, PRT/GT, etc. because the high molecular component is compatible with the high molecular polymer. The result is favorable when treatments are combined.

(5) Used to make polar resins tougher

Thermoplastic elastomer may be used as a toughening agent for PP, PE, PS, PA, and other plastics by adding a little quantity of compatibilizer. It has good softness, high elasticity, and low temperature performance. The most important “core” and “shell” compatibility of these tougheners is the compatibilizer. Using EPDM grafted MAH toughening agent as an illustration, it is possible to preserve outstanding physical attributes and toughness at a temperature of -45°C. The general dosage is 5%-10%.

(6) Used to enhance the functionality of plastics

Compatibilizers can also be used to enhance the surface qualities of plastics, such as gloss, printability, and antistatic adherence.

Effect

enhance the two polymers’ compatibility, enhance their adherence to one another, create a stable structure, and uniformize the scattered phase and continuous phase, or compatibilize, the two polymers. There are groups in the compatibilizer’s molecule that can physically or chemically connect with the two polymers, which explains why it can compatibilize two polymers with dissimilar characteristics.

Prestazioni

The so-called compatibilizer, which is introduced to the incompatible polymer system and in a certain way, may be thought of as a surfactant in terms of thermodynamics. However, the compatibilizer utilized in the polymer alloy system typically has a larger molecular weight. The compatibilizer will be confined on the interface between the two polymers after mixing and kneading at a high temperature, which will lower interfacial tension, thicken the interfacial layer, and decrease the size of dispersed particles. As a result, the system will eventually form a macroscopically uniform Thermodynamically stable phase structure that is characterized by microscopic phase separation.