Composites are prepared by combining two or more other materials together, so that they complement and improve each other, but also retain their own unique characteristics in the final product.

Due to their excellent properties, composites have been used in a wide range of applications, and this series of articles will provide a comprehensive overview of the main areas of application for composites, which include: aerospace, automotive industry, construction, energy, energy storage, infrastructure, marine, pipelines and tanks, sports and recreation, transport and ten other areas.

Aerospace

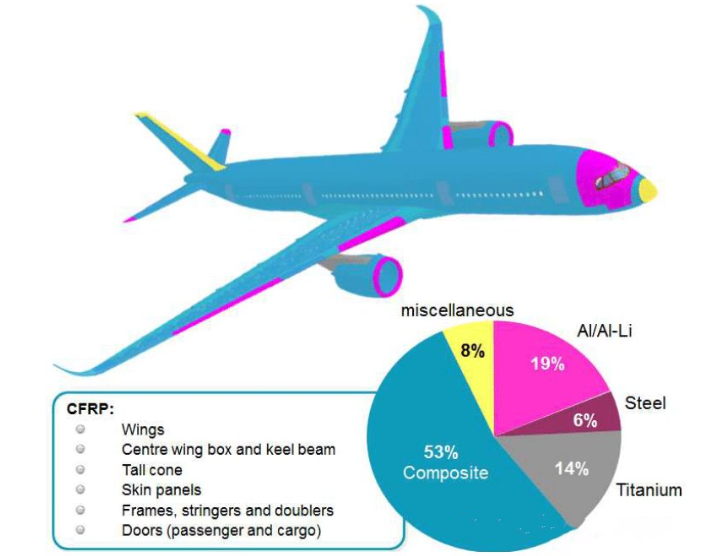

Major aerospace original equipment manufacturers such as Airbus (Europe) and Boeing (USA) have shown potential for large-scale applications of composites in aviation, while NASA has been seeking composites manufacturers to provide innovative composite solutions for rockets and other spacecraft.

The proportion of composite materials has increased with each new generation of aircraft developed by Boeing, with the Boeing 787 Dreamliner reaching a maximum of over 50%. The main structural components of the Boeing 787 Dreamliner are made from more carbon fibre “sandwich” composites and advanced carbon fibre laminates, thus moving away from the obsolete glass fibre composites.

On the other hand, aramid fibres are used extensively in the construction of leading and trailing edge wing assemblies as well as very stiff, very light bulkheads, fuel tanks and floors. In addition, advanced composites made from a combination of high-strength, rigid fibres embedded in common matrix materials are also widely used in the aerospace industry.

Industria automobilistica

As the largest end-use market for composites, the automotive industry is no stranger to composites. In addition to pioneering vehicle design, composites help make vehicles lighter and more fuel-efficient. Vehicles need reliable, synchronized mechanisms with components that can withstand friction, corrosion and temperature fluctuations.

Inaccuracies in design or production will affect performance and can cost manufacturers business. Compared to metallic steel, composite materials can meet and exceed the needs of the automotive industry. These unique properties include

Low coefficient of thermal expansion

Excellent dimensional stability for shape retention and reliability

Corrosion resistance in wet and dry conditions

High impact strength to withstand repeated use

Relatively low weight to reduce the overall mass of the vehicle

Better sound insulation and better performance

Acceptability to paint, including the ability to meet Class A surface requirements, painting and baking processes

Ease of manufacture and relatively low cost

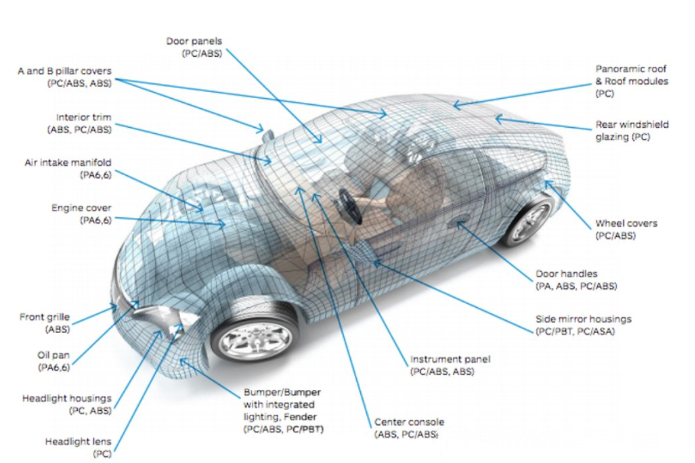

Typical applications of composite materials in automotive interior and exterior structures

To date, composites have been used in a wide range of automotive structural components, from headlight housings for headlamps to electrical and insulation components under the hood, to exterior auto body parts, interior structures and trim components. The following are examples of common applications of composites in automotive components:

Deflectors and spoilers

Air intake manifolds

Battery housings and covers

Bumpers and bumper cross members

Cylinder heads (e.g., valves, rocker arms, cams) covers

Window/sunroof frames

Front end grille opening panels

Front headlight housings

Heat shields (e.g., engine, transmission)

Pillars and coverings

Construction field

The architectural community is experiencing significant growth in the understanding and use of composites. Composites offer high performance and value to architects and designers on large projects, and they are increasingly being used in commercial and residential buildings.

In a recent article, the Palari Group builds sustainable 3D printed communities and homes, Mighty Buildings is a building technology company that uses 3D printing, robotics and automation to create affordable and sustainable homes. The basic building block of the house is the Mighty Panel, a 3D printed 100% polymer composite panel with structure, insulation, MEP integration, air/moisture/fire barrier and interior/exterior finishes. mighty Buildings prints individual panels at its factory and then assembles them into the house at the construction site.

The high strength properties of carbon fiber are playing an active role in the construction sector. Carbon fiber is extremely strong, soft and easy to lay down, and can be used to repair and reinforce buildings to make them look like brand new buildings. Carbon fiber laminates are widely used to increase the load-bearing capacity of floors and columns. In addition, carbon fiber can resist earthquake damage, so it can also be used for structural reinforcement of new buildings and as an alternative to steel prefabricated parts.

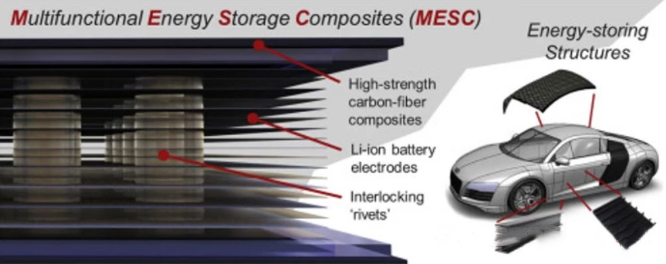

Energy storage field

Multifunctional Energy Storage Composites (MESC) are used to help improve mechanical properties by embedding the battery layer into the structure and interlocking rivets to hold the battery layer in place. Experimental tests show that MESC can have electrochemical behavior comparable to other materials. And compared to soft pack cells, MESC achieves 15 times higher mechanical stiffness at 60% encapsulation efficiency.

Other representative applications of composites in energy storage include:

Hydrogen tanks for aerospace applications

Hydrogen fuel cell systems

Natural composite material batteries

Infrastructure

While there is no strict distinction between infrastructure and construction in the strictest sense, infrastructure construction has entered a new phase in recent years with the advent of new, low-cost, high-performance structural composites. Not only can fiber-reinforced plastics (FRP) replace steel in many load-bearing structures, but reinforcing concrete beams with fiber-reinforced plastics (FRP) bonded internally or externally has also proven to be feasible.

Composites made of glass, aramid or carbon fibers are increasingly being considered for pre-tensioned, post-tensioned or reinforced concrete. To replace corroded steel, FRP systems may eventually be used in concrete bridge decks or other outdoor concrete floor structures.

Corrosion resistance properties are one of the main factors that make carbon fiber so desirable in infrastructure applications. Carbon fibers do not corrode and rust, so carbon fiber concrete layers can be thinned considerably because they do not require the same corrosion protection as steel cores, which greatly reduces the amount of concrete used in a building, with other benefits such as reduced costs, faster construction schedules, and shorter drying times. In addition, because of its good electrical conductivity, carbon fiber can be used to shield electromagnetic interference and can transmit information about building parameters, becoming an integral part of intelligent buildings.