As a sports event held every four years, this year’s World Cup in Qatar continues to attract countless fans. During the September-November period, peripheral products related to the World Cup became the search keywords on Ali International Station, and the number of global buyers of football shoes increased by nearly 100%

How important is the right pair of sneakers? It can not only maximize your football skills, but also protect your feet very well, which greatly enhances your fun and satisfaction in the process of playing football.

![]() 01 shoe leaking problem

01 shoe leaking problem

When it comes to football boots, water leakage is the first problem to be solved. Assuming that in the uncontrollable situation of rain, the shoes leak and the players will not be able to enjoy the game happily.

What happened to the leaking shoe?

Water leakage in shoes is mostly due to the degumming of the joints of the shoe materials. Affected by external factors such as temperature, oxygen, water, acid-base salts, impurities, mechanical damage, etc., the composite coating glue or the bonding layer of the composite surface of the shoe materials is aging, and the polymer is damaged. destroy.

![]() 02 The role of grafted compatibilizer in shoe materials

02 The role of grafted compatibilizer in shoe materials

Therefore, in production, composite bonding is one of the key links in shoe production.

It runs through all aspects of shoe production, such as sole bonding, vamp bonding,

insole bonding, etc. The bonding performance of hot melt adhesives is very important.

Hot-melt adhesives are widely used in the shoe industry because of their environmental protection,

solvent-free, extremely low VOC, and convenient processinThe key material that affects the bonding performance of hot-melt adhesives is the grafted phase

with strong polarity and high peel strength. Toner.

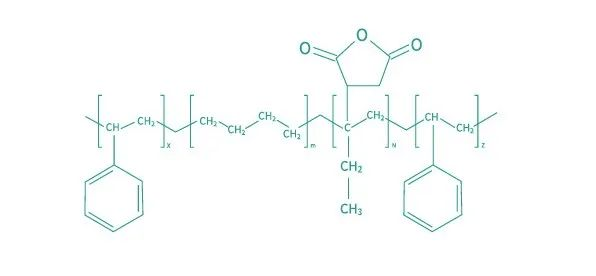

There are many types of graft compatibilizers, and there are many monomers used for grafting.

The commonly used ones are: maleic anhydride (MAH), glycidyl methacrylate (GMA), styrene (St), methyl methacrylate (MMA) ), butyl acrylate (BA), acrylic acid (AA), epoxy resin, oxazoline, etc.

These compatibilizers are only different in monomers, and the principle is similar: use free radicals to initiate into the mixture of monomers and polyolefins Grafting reaction can be carried out.

Among them, the maleic anhydride (MAH) graft compatibilizer is the most polar

because of the maleic anhydride monomer, and the graft compatibilizer produced by the same

base material is also the most polar, so it is also the most widely used, and it is widely used in shoe materials. Tons of applications.

![]() 03 Classification of Graft Compatible Hot Melt Adhesives

03 Classification of Graft Compatible Hot Melt Adhesives

There are five main categories of hot-melt adhesives for footwear: EVA hot-melt adhesive film,

TPU hot-melt adhesive film, PES hot-melt adhesive film, PA hot-melt adhesive film, and PO hot-melt adhesive film. The grafted compatibilizers that can be added include grafted POE, grafted PE, grafted SEBS, and grafted EPDM, in addition to the most widely used grafted EVA.

click to check more TDS

![]() 04 Specific application of graft compatible hot melt adhesive

04 Specific application of graft compatible hot melt adhesive

The application parts of grafted compatibilizer hot melt adhesive mainly include shoe uppers,

insoles, shoe labels, foot pads, heels, setc.

(1) Fitting of the non-sewn upper to the inner of the shoe

Mainly for sports shoes, it is used for the lamination of shoe uppers, mesh and other materials,

and is used for high-frequency machine hot-press bonding of shoe upper leather and mesh.

The upper does not need needle and thread sewing, and it is mainly used for EVA instead of

traditional glue. Insoles, PU insoles, PU soles, rubber soles, EVA soles, etc. fit the feet and heels.

(2) Bandage

The upper is to nail the inner sole of the shoe to the plant with the upper, and then use an adhesive

to firmly bond the upper and the inner sole. The compatible agent type hot melt adhesive used in

the banding requires short sticking time and high bonding strength, and the bonding process is

completed once on the banding machine. Most of the graft-compatible hot melt adhesives are

pre-formed into strips, and then transported to the bonding part of the upper and the inner sole,

and heated and pressed for a few seconds to complete the bonding operation of the upper.

(3) Sticky outsole

Outsoles account for the largest share of hot melt adhesives used in the shoe industry. Since the

outsole and the upper require high bonding strength, polyester hot-melt adhesives with high

crystallinity and high cohesive strength are generally used.

(4) Bonding the main heel and Baotou

Using graft-compatible hot-melt adhesives to glue the main heel and toe cap can eliminate the

necessary drying procedures for water-based and solvent-based adhesives and shorten the production

cycle. If it is a soft toe cap, use a small extruder to directly extrude the compatible hot melt adhesive

to the toe cap on the inner surface of the upper and spread it into a toe cap shape.

After the hot melt adhesive cools, it becomes a soft toe cap, and there is no need to re-line it.

(5) Adhesion of uppers of shoes and rubber shoes

In addition to environmental protection factors, the use of graft-compatible hot-melt adhesives is also

an important reason for high efficiency, straight shoe materials, moisture-proof, anti-corrosion,

and good hygienic performance. The dot coating process keeps the fabric well ventilated and makes

up for the deficiencies of gasoline glue and latex in these aspects.