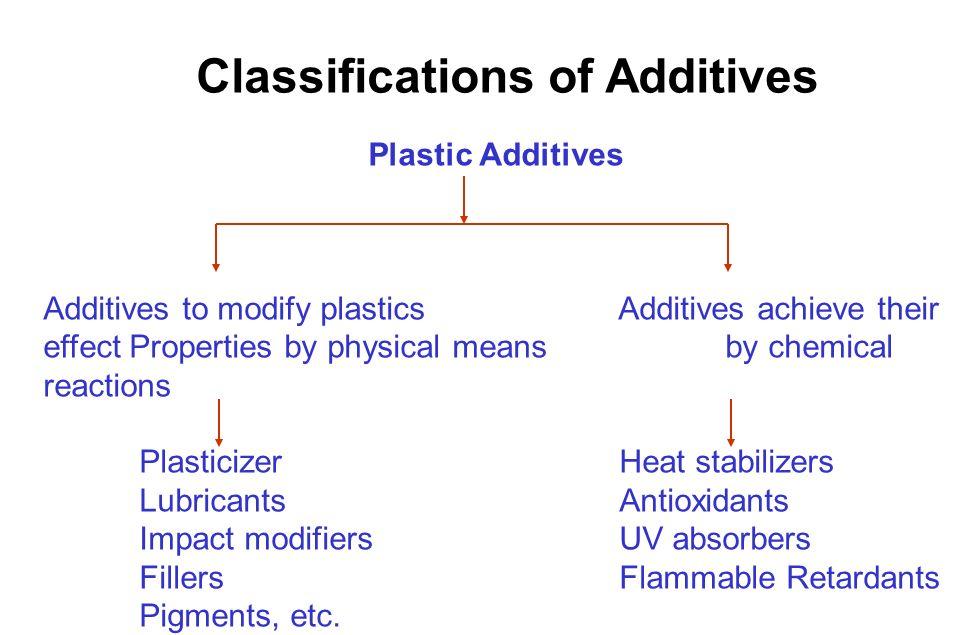

Plastic additives, commonly referred to as plastic additives, are substances added to polymers (synthetic resins) to enhance processing performance or to enhance the qualities of the resin itself during molding.The primary goals are to enhance the polymer's performance during processing, as well as to improve the conditions for processing, increase processing effectiveness, enhance product performance, and extend product life and value.

01 Heat Stabilizer

(1) Stabilizer

The primary applications for heat stabilizers are polyvinyl chloride and its copolymers. A limited number of molecular chains in polyvinyl chloride break during heat processing, releasing hydrogen chloride as they do so. Chain reactions using hydrogen chloride hasten the breakdown of molecular chains.

Because of this, processing polymers like polyvinyl chloride will become impossible if the recently degraded hydrogen chloride is not removed quickly enough. Instead, the polymer chain will continue to break down into low-molecular components. In order to stabilize polyvinyl chloride, the degraded hydrogen chloride can be quickly neutralized by adding the suitable alkaline materials.

Main stabilizers and auxiliary stabilizers are two categories for commonly used thermal stabilizers.

Salts and soaps with heavy metal cations, such as lead, calcium, cadmium, zinc, barium, aluminum, lithium, strontium, etc., are the major sources of stabilizer. The most popular ones among them are lead sulfate and lead stearate.

Epoxidized oils and esters are referred to as auxiliary stabilizers, and they also serve as some types of plasticizers.

(2)antioxidant

Chemical compounds fall within the category of antioxidants. They can delay or prevent the oxidation process of a polymer when present in modest quantities in a polymer system, extending the polymer's useful life. According to their chemical makeup and mode of action, commonly used plastic antioxidants may be broadly categorized into five groups: hindered phenols, phosphites, sulfides, composites, and hindered amines (HALS).

(3)UV absorbers

When polymers are exposed to UV light, photodegradation occurs. A group of chemical compounds known as ultraviolet absorbers have the ability to either absorb or lessen the transmission of ultraviolet radiation. They have the ability to do energy conversion, converting thermal energy or longer, non-destructive light waves from high-energy UV light. UV deterioration is prevented by polymers.

According to their chemical makeup, UV absorbers may be categorized into the following groups: salicylates, benzophenones, benzotriazoles, substituted acrylonitriles, triazines, and hindered amines.

(4) A light shielding substance

A chemical known as a light shielding agent may absorb light waves that injure polymers, transform that light energy into heat energy, scatter or reflect light waves, and shield polymers as a result. Among the most common light-blocking substances are carbon black, zinc oxide, titanium dioxide, and lithopone.

2.Processing tools

Processing aids are additives, mostly plasticizers and lubricants, that are used to enhance the processing rheology and molding performance of plastics. They often have low viscosity or surface energy.

(1)Plasticizer

Plasticizers can diminish the crystallinity of polymer molecular chains, enhance the flexibility, extensibility, and plasticity of plastics, and decrease the flow of plastics. They can also improve the mobility of polymer molecular chains by reducing the van der Waals interaction between polymer molecules. Hardness and temperature are favorable for the molding of plastic items. Phthalates, sebacates, chlorinated paraffins, etc. are examples of commonly used plasticizers.

The two groups of plasticizers are primary plasticizers and secondary plasticizers. The primary plasticizers have good resin compatibility, high plasticizing efficiency, migration resistance, low volatility, low oil (water) extractability, and low temperature flexibility. Secondary plasticizers, on the other hand, have poor resin compatibility and are typically used in conjunction with primary plasticizers to cut costs.

(2) lubricant

It may increase the fluidity of the resin, achieve adjustable resin plasticization time, and sustain continuous production by reducing friction and adhesion between the particles of each layer of plastic, the melt, and the metal surface of the processing equipment. lubricant.

Internal and exterior lubricants are two categories of lubricants.

The primary purpose of the external lubricant is to facilitate the smooth removal of the polymer melt from the hot metal surface of the processing apparatus. Only a thin lubricant layer forms at the contact between the polymer and the metal due to the low compatibility between the external lubricant and the polymer. Stearic acid and its metal salts are the most widely used external lubricant.

A high compatibility between the internal lubricant and the polymer can lessen the cohesion between the polymer molecules, allowing the polymer to flow more easily and lowering the temperature increase brought on by internal friction heat. Low molecular weight polyethylene, etc., is the internal lubricant that is most frequently utilized.

(3) Agent of release

A useful material serving as a barrier between the mold and the end product is the release agent. Mold release agents are resistant to chemicals and do not disintegrate when in contact with various resins, particularly those that include styrene and amines. The release agent sticks to the mold and does not transfer to the workpiece to be treated; it also resists heat and stress and is hard to breakdown or wear. It does not obstruct painting or other secondary processing processes. The amount of release agent has also greatly grown as a result of the quick growth of injection molding, extrusion, calendering, molding, laminating, and other processes.

03 Coupling agents, fillers, and reinforcement materials

Fillers and reinforcing components make up a sizable amount of many plastics. The main goal is to increase the strength and stiffness of plastic goods or lower production costs by adding different fiber components or inorganic compounds. The most popular fillers and reinforcement materials are metal oxide, glass fiber, asbestos, quartz, carbon black, silicate, and calcium carbonate.

A coupling agent is a member of a family of compounds that can enhance the qualities of the interface between fillers or reinforcement and polymer materials. The coupling agent often has two functional groups: one that can chemically react with the polymer matrix or has higher compatibility, and the other that can create chemical bonds with reinforcing materials or inorganic elements.

For instance, the general formula for silane coupling agent is RSiX3. (R is an active functional group with affinity and reactivity with polymer molecules, such as vinyl, chloropropyl, epoxy, methacryl, amine and mercapto etc.; X is an alkoxy group that may be hydrolyzed, such as methoxy, ethoxy, etc.).

The surface of the reinforcing material or filler can undergo chemical modification following application of a coupling agent, and a bridge bond is created between the continuous polymer and the dispersed inorganic phase to create a composite material, increasing the strength of the reinforcing material. Organosilane, which plays the part of fillers, is the most often used coupling agent, and organic titanate, which is a more effective coupling agent.

04 Auxiliaries that alter the resin's chemical composition and physical shape include:

(1) Cross-linking agents

Rubber and thermosetting resins are two polymer compounds that frequently utilize crosslinking agents. Polymer materials have a linear molecular structure, which means that without crosslinking, they have poor strength, are easily broken, and have no flexibility. In order to attach the linear molecules to one another, the crosslinking agent creates chemical connections between the molecules. Create a network structure to increase the rubber's flexibility and strength. Mostly sulfur and an accelerator are utilized as the crosslinking agents in rubber.

The term "cross-linking agent" for plastic often refers to an organic peroxide, like the dicumyl peroxide that may be used for polyethylene cross-linking.

(2)foaming agent

Within a given viscosity range, a foaming agent can transform rubber and plastic into a liquid or plastic state and create a microporous structure. According to their mode of operation, foaming agents can be classified as either physical foaming agents or chemical foaming agents. Chemical foaming agents are thermally degraded at a certain temperature to create one or more gases to foam the polymer; physical foaming agents are a family of chemicals that rely on the change of their physical state during the foaming process to achieve the objective of foaming.

(3) An enzymatic agent

Plastics with imperfect crystalline structures, like polyethylene and polypropylene, can use the nucleating agent. By altering the resin's crystallization behavior, it can reduce the molding cycle, enhance product transparency, and smooth out the surface by accelerating crystallization, increasing crystallization density, and promoting grain miniaturization. For physical and mechanical characteristics including gloss, tensile strength, stiffness, thermal distortion temperature, impact resistance, and creep resistance, new functional additives are now available.

05colorant

Because colorants are not soluble in ordinary solvent chemicals, mechanical means must be used to evenly distribute the pigments throughout the plastic in order to get the best coloring performance. Organic pigments have a low relative density, a wide color spectrum, a high color power, and great thermal and light stability compared to inorganic pigments' comparatively weak color power and high relative density. Heat resistance, weather resistance, and covering are the drawbacks. In comparison to inorganic pigments, strength and other qualities are inferior. Masterbatches and fluorescent whitening agents make up the majority of colorants.

(1)Masterbatch

A masterbatch is a mixture created by evenly dispersing extra-normal pigments or colors into resin. It has the following benefits: it helps to maintain the chemical stability and color stability of the pigment, improves the pigment's ability to disperse, is simple to use, makes it simple to change color, is environmentally friendly, and saves time and raw materials.

(2) A fluorescing bleaching agent

A fluorescent whitening agent is a sophisticated chemical molecule that is also a type of fluorescent dye, or white dye. Its unique property is the ability to induce fluorescence from incoming light, giving colored materials a shimmering appearance that is visible to the naked eye. The material was very white. They may be loosely separated into carbocycles, triazinylamino stilbenes, stilbene-triazoles, benzoxazoles, furans, benzofurans, and benzene according to the parent categorization of luminous whitening agents. There are nine groups, including miscellaneous, coumarins, 1,3-diphenylpyrazolines, imidazoles, and naphthalimides.

06 Functional Auxiliary

(1) A bacterial inhibitor

As people's awareness of safety continues to rise, an increasing number of individuals are beginning to purchase antibacterial plastic items. Antibacterial polymers include antibacterial agents. Antibacterial agents are chemicals that, for a predetermined amount of time, can prevent the development or reproduction of specific microorganisms (bacteria, fungus, yeast, algae, viruses, etc.) from rising over what is necessary. Bacteriostatic and bactericidal compounds are known as antimicrobials.

(2) Fire-resistant

Flame retardants are substances added to polymers that reduce the rate of burning. The majority of polymers that include flame retardants either self-extinguish or delay the pace of combustion.

(3)Antistatic agent

Any thing has a static charge of either a positive or negative sign. Antistatic agents are chemicals that direct or remove the accumulated detrimental charges so they do not impede or hurt production or human life. The accumulation of static charges affects or even harms industrial production and human life. In general, antistatic compounds resemble surfactants in that they contain both polar and non-polar groups in their structure.

Anions of carboxylic acid, sulfonic acid, sulfuric acid, phosphoric acid, cations of amine salt, quaternary ammonium salt, and groups such as -OH, -O- are among the frequently used polar groups (i.e. hydrophilic groups); commonly used non-polar groups (i.e. lipophilic groups or hydrophobic groups) include alkyl groups, alkaryl groups, and the like. Antistatic agents can be categorized into five categories: amine derivatives, quaternary ammonium salts, sulfate esters, phosphate esters, and polyethylene glycol derivatives.