Coace® W1L is a general purpose LLDPE-g-MAH product with excellent all-round performance. It has the reactive and strong polarity of maleic anhydride polar molecules, which can improve the interfacial affinity between polyolefin substrates and inorganic materials such as mineral powder, inorganic flame retardants, wood flour and starch, thus achieving enhanced composite strength, and is widely used in low smoke and halogen free flame retardant cable compounds.

☞ Typical application one

W1L improves the tensile properties of low smoke and halogen-free flame retardant cable materials

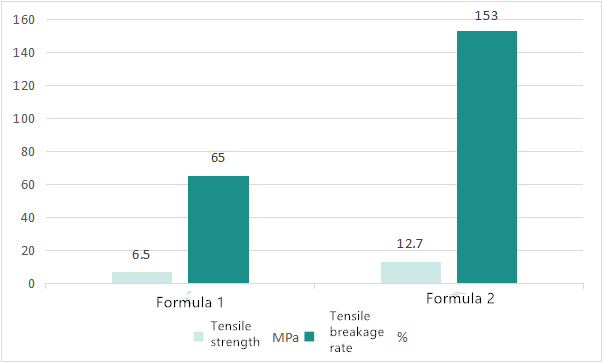

Formula 1: Magnesium hydroxide/MH-8800: LLDPE/FL201XV/ExxonMobil: EVA/7350/FMT: W1L=60:20:20:0

Formula 2: Magnesium hydroxide/MH-8800: LLDPE/FL201XV/ExxonMobil: EVA/7350/ Formosa Plastics: W1L=60:15:20:5

As can be seen from the above graph, the addition of 5wt% W1L increases the tensile strength of the low smoke halogen free flame retardant cable compound system by 90% and the elongation at break by 135%.

☞ Typical application II

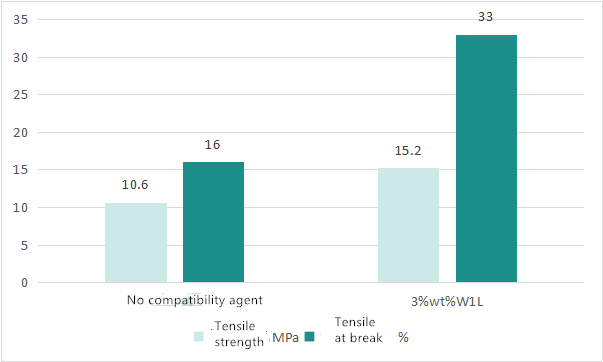

Effect of W1L on the tensile properties of talc (20wt%) filled LLDPE system

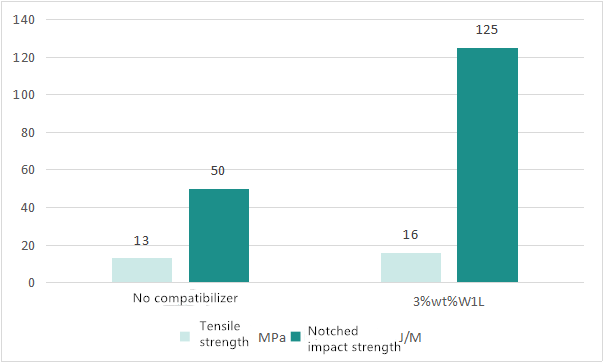

Effect of W1L on flexural and impact properties of talc (20wt%) filled LLDPE systems

From Figures II and III above, it can be seen that the mechanical properties of talc (20wt%) filled LLDPE composites can all be improved by adding 3wt% W1L, with the notched impact strength improving by 150% and the elongation at break improving by nearly 110%.