01 Polybutylene terephthalate (PBT)

A relatively new class of thermoplastic engineering plastics developed and industrially produced by Celanese Corporation in the 1970s, with the following properties.

| Advantages | Disadvantages |

| Fast crystallisation, rapid moulding | High crystallisation shrinkage, poor dimensional stability |

| Low water absorption | Sensitive to chipping |

| Good weather resistance,suitable for outdoor use | |

| Excellent mechanical properties | |

| Outstanding friction and wear resistance, less wear than POM |

PBT has many advantages, but its application is limited by these two outstanding disadvantages.

02 Acrylonitrile-butadiene-styrene plastics (ABS)

ABS resin is by far the most produced and widely used plastic and is relatively inexpensive. It not only has a balance of tough, hard and rigid mechanical properties, but also has good dimensional stability, surface gloss, low temperature resistance, colouring processability and processing fluidity.

It can be expected that blending ABS/PBT together will produce a plastic alloy with excellent performance and achieve high resin performance.

However, ABS/PBT alloys are incompatible systems and direct blending of the two is prone to delamination, peeling and poor material properties, so compatibilisers are key to the preparation of ABS/PBT alloys.

The right compatibiliser can produce a high performance alloy.

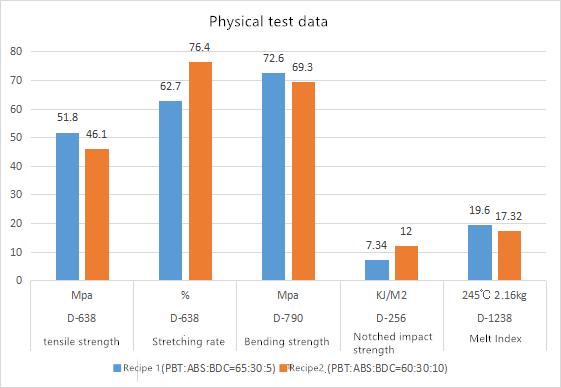

Our in-house developed product, BDC, provides excellent compatibility solutions for ABS/PBT alloys, maximising the mechanical, thermal and plating properties of the plastic alloy system.

Note: Graphical data is for a PBT/ABS alloy, at a host speed of 400, a feed of 12, a humidity of 50% and a temperature of 25°C.