Reinforced nylon, monomer casting nylon (MC nylon), reaction injection molding (RIM) nylon, aromatic nylon, transparent nylon, high impact (super strong) nylon, electroplated nylon, conductive nylon, flame retardant nylon, etc. are only a few of the many modified variants of nylon.

Let’s discuss a few of the more prevalent modified nylons.

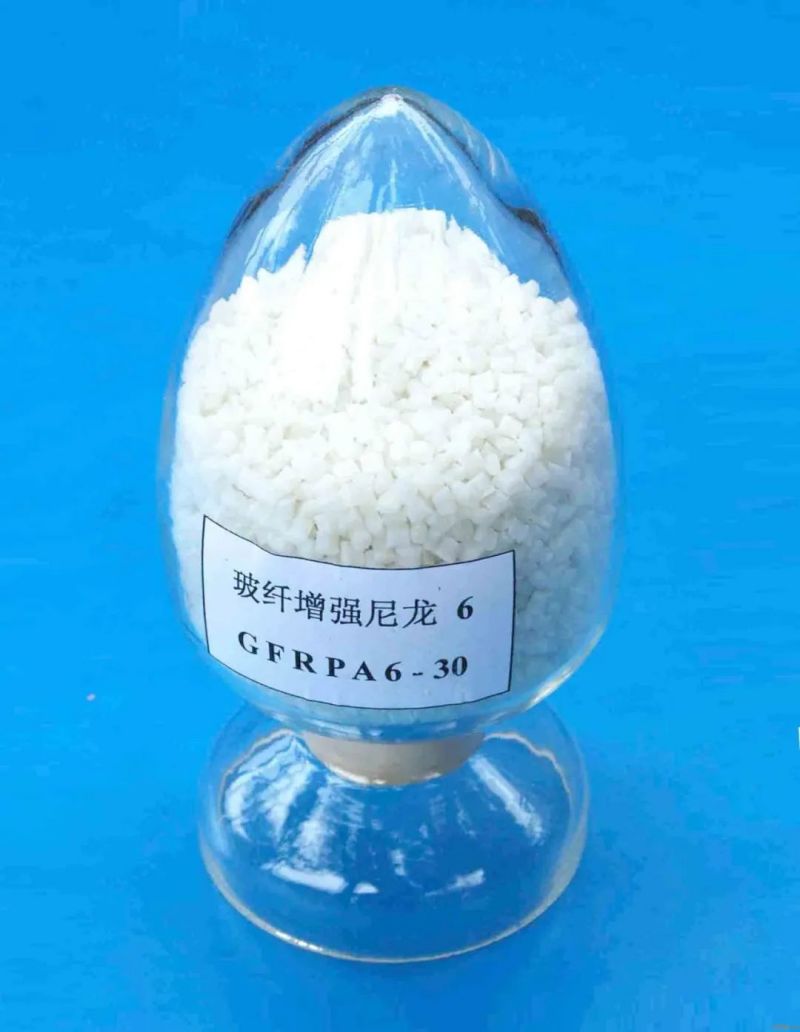

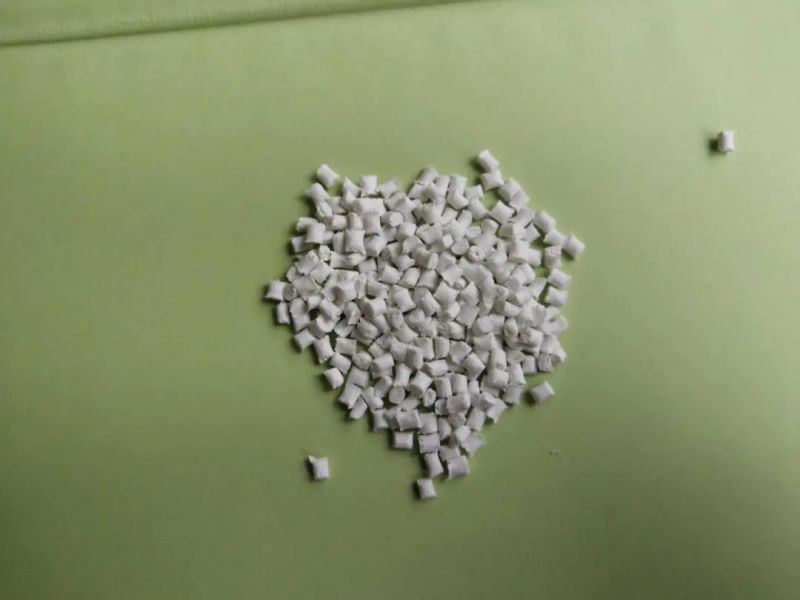

1 bolstered nylon

Strength and modulus are greater with reinforced nylon. The tensile strength and bending strength of nylon are substantially increased with the inclusion of glass fiber or carbon fiber, and the impact strength is complicated. The addition of a toughening agent increases the toughness of nylon. Significant improvement; 30% to 35% of glass fiber and 8% to 12% of a toughening agent are added, giving reinforced nylon its full range of mechanical qualities.

2 thorny nylon

Numerous engineering polymers are unable to function in particular application environments. For instance, many materials are either too brittle or not sturdy enough. By incorporating tougher components or extremely fine inorganic compounds, nylon’s toughness and low-temperature performance can be improved.

Toughener: An ingredient added to the resin to increase the plastic’s impact strength and elongation while lowering its brittleness after hardening.

3 nylon that doesn’t burn

Materials must be flame retardant in many businesses, including those that manufacture electrical products and vehicles, however many plastic raw materials have poor flame retardancy. Flame retardants can now be added to materials to increase their flame resistance.

The majority of these functional additives are compounds of the VA (phosphorus), VIIA (bromine, chlorine), and IIIA (antimony, aluminum) group elements. They are also known as flame retardants, fire retardants, or fireproofing agents.

In addition to being flame retardants, molybdenum compounds, tin compounds, and iron compounds that have smoke-suppression properties are mostly appropriate for plastics that need flame retardancy to delay or prevent burning of plastics, particularly polymer plastics. It takes longer to light, ignites self-extinguishing, and is challenging to ignite.

4 climatically resilient nylon

Plastics become brittle at low temperatures because of their innate low-temperature brittleness. Cold resistance is thus typically necessary for many plastic items utilized in low-temperature situations.

Weather resistance is a term used to describe a group of aging events that occur to plastic items over time as a result of exposure to sunshine, temperature fluctuations, wind, rain, and other environmental factors. These aging phenomena include fading, discoloration, cracking, pulverization, and strength decrease. One of the main causes of plastics aging is UV exposure.

5 alloy nylon

To prepare two or more materials into a new material with high performance, functionality, and specialization—either to merge two materials or to increase the performance of one—we utilize physical blending, chemical grafting, and copolymerization techniques. the function of material characteristics. It lowers expenses while enhancing or improving the performance of current polymers.

The production technique for general-purpose plastic alloys, such PA, PVC, PE, PP, and PS alloys, has mostly been mastered.

Engineering plastic alloys are mixes of engineering plastics (resins), mostly based on engineering plastics like polyoxymethylene (PA), polypropylene (PPO), polytetrafluoroethylene (PTFE), and ABS resin-modified sex products.

6 reinforced nylon that is robust

It is primarily classified into modified engineering plastics with glass fiber reinforcement, toughened and weather-resistant nylon special materials, and other items.

This new polypropylene material has the qualities of engineering plastics and is weather-resistant and hardened. It benefits from high stiffness, minimal molding shrinkage, superior low-temperature toughness, and great weather resistance.

It is mostly employed in outdoor settings where resistance to weather and UV radiation is necessary. Companies that manufacture appliances for the home and car parts are its two primary consumer categories.