Description des produits

W1H is a general-purpose HDPE-G-MAH product with excellent comprehensive properties. It contains maleic anhydride and has strong plasticity, which can improve the properties of polymerization and matrix minerals, and the surface roughness of inorganic substances, reaching The effect of enhancing the strength of composite materials.

By enhancing compatibility, mechanical characteristics, and processability in polymer blends, the Universal HDPE-G-MAH Compatibilizer for Polyolefin Materials provides outstanding value and performance. This compatibilizer transforms the compatibility and performance of polyolefin blends with its distinctive HDPE-G-MAH structure, improved interfacial adhesion, and broad range of application compatibility. Buyers in a variety of industries, such as consumer products, packaging, construction, and automotive, can gain improved compatibility, excellent mechanical qualities, a wide processing window, and cost-effectiveness by integrating this compatibilizer into their manufacturing processes. The compatibilizer is a highly attractive option for producers looking to improve cost-effectiveness, compatibility, and performance in polyolefin blend applications because of its remarkable features and benefits.

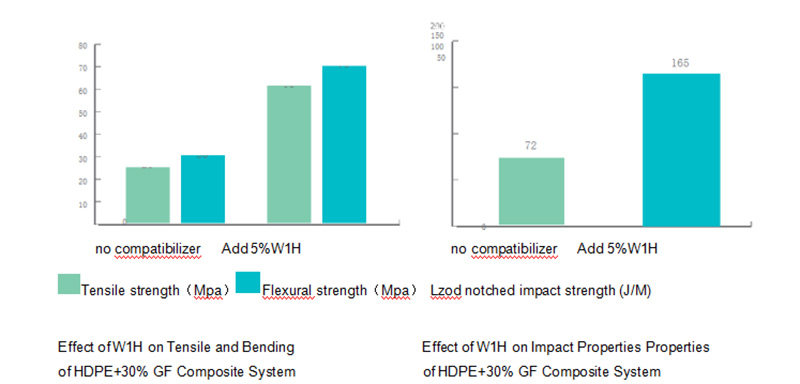

Application effect of W1H in glass fiber (30%) reinforced HDPE:

Remarque :HDPE raw material uses DOW K T 10 0 0, glass fiber uses Jushi 98 8 A

It can be seen from the figure that in the 30% glass fiber reinforced HDPE system, adding 5% Kolibang®W1H can greatly improve the tensile strength, bending strength and notched impact strength of the material system, and the coupling effect is remarkable.

Un équipement de pointe !

Elle est équipée de lignes de production avancées et d'un centre d'essais expérimentaux pour garantir la qualité des produits.

Une force technique puissante !

Plus de 10 techniciens expérimentés en recherche et développement sont à l'origine d'une innovation permanente.

recommendation Technical Support After-sales protection

Caractéristique

| Test items | Données d'essai | Detection method |

| densité | 0.95 g/cm³ | ASTM D792 ISO 1183 |

| melting point | 130℃(266℉) | ASTM D3418 ISO 3146 |

| Melt finger | 1-3(190℃,2.16kg)g/10min | ASTM D1238 ISO 1133 |

| Taux de greffe | Haut | titrage acide-base |

| Extérieur | particles |

W1H est un produit HDPE-G-MAH à usage général doté d'excellentes propriétés globales.

- HDPE-G-MAH Structure: The compatibilizer is made of high-density polyethylene (HDPE) with a grafted maleic anhydride (MAH) structure connected to the backbone. The compatibility and interfacial adhesion of different polyolefin materials in blends are improved by this special structure.

- Enhanced Interfacial Adhesion: Polyethylene (PE) and polypropylene (PP), two incompatible polyolefin materials, are made to adhere to one another more strongly by using the HDPE-G-MAH compatibilizer. By establishing a compatible interface, it lessens phase separation and enhances the mechanical characteristics of blends of polymers.

- Better Thermal resilience: The compatibilizer can tolerate high processing temperatures without degrading because of its outstanding thermal resilience. This feature guarantees compatibility and reliable performance across a range of manufacturing methods.

- Flexible Application Compatibility: A broad variety of polyolefin materials, such as PE and PP, and their different grades, are compatible with the Universal HDPE-G-MAH Compatibilizer. Because of its adaptability, it can be integrated into a variety of polymer systems to provide specialized solutions for certain application needs.

Avantage

- Improved Compatibility: By considerably enhancing the compatibility between various polyolefin materials, the HDPE-G-MAH compatibilizer makes it possible to create polymer blends with uniform structures and better mechanical qualities. It improves interfacial adhesion, minimizes phase separation, and maximizes the performance of the finished product.

- Better Mechanical Properties: The compatibilizer makes polyolefin blends have better mechanical properties by lowering phase separation and increasing interfacial adhesion. More elongation at break, impact resistance, and tensile strength are increased, making the products stronger and longer-lasting.

- Extrusion, injection molding, blow molding, and other production processes are all supported by the compatibilizer’s large processing window, which is made possible by its exceptional temperature stability and varied compatibility. It offers producers adaptability and processing simplicity in a range of production settings.

Notre avantage

Chaîne d'approvisionnement mondiale !

Sound Storage And Logistics Supply Chain System (système de chaîne d'approvisionnement)

Support technique

Protection après-vente

Concentration - Réalisation - Excellence !

Produits personnalisés

Priorité à la R&D

Services globaux

Certification Coace !

Certification ISO9001:2015

Certification ISO14001:2015

Enregistrement REACH dans l'UE

Corée K-REACH pré-enregistrement

L'avantage de l'entreprise !

Disposition à l'intérieur et à l'extérieur du pays, idéal pour les mélanges

Schéma de commercialisation intérieure

Mise en place d'un marketing outre-mer

Application

1. Peut être utilisé comme compatibilisant pour les matériaux de câbles retardateurs de flamme sans halogène et à faible dégagement de fumée ;

1. Peut être utilisé comme compatibilisant pour les matériaux de câbles retardateurs de flamme sans halogène et à faible dégagement de fumée ;2. Il peut être utilisé comme améliorateur de surface pour les feuilles/plaques extrudées, ce qui permet d'améliorer efficacement la planéité de la surface du matériau et d'éliminer les irrégularités et les piqûres à la surface du matériau ;

3. Il peut être utilisé comme compatibilisant pour le polyéthylène et la fibre de verre afin de promouvoir la compatibilité du polyéthylène et de la fibre de verre ;

4. Il peut être utilisé comme compatibilisant pour les mélanges-maîtres ayant le PE comme support, tels que les mélanges-maîtres colorés, les mélanges-maîtres ignifuges, les mélanges-maîtres fonctionnels, etc ;

5. Il peut être utilisé comme modificateur pour prolonger la période anti-buée du paillis anti-buée.