Introduction: There is a lot of rivalry among the many materials vying for the top rank in the elastomer industry. A comparison of modified PP, POE polyolefin elastomer, and EPDM is one example. Both materials have distinctive qualities and uses, but which is superior?

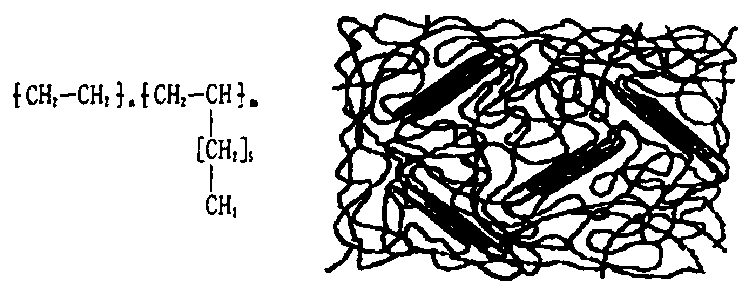

Modified Polyolefin Elastomer (POE), PP: Modified PP, POE polyolefin elastomer is a flexible, impact-resistant polymer with outstanding weatherability. Combining the qualities of polypropylene (PP) with polyolefin elastomer (POE), it is a thermoplastic elastomer. A material with great elasticity, a low compression set, and strong resistance to chemicals and UV radiation is the consequence of this combination. Electrical insulation, consumer items, and automobile parts all use modified PP, POE polyolefin elastomers.

EPDM: Also known as ethylene propylene diene monomer (EPDM), this synthetic rubber finds extensive application across a number of sectors. It is renowned for its exceptional ozone resistance, electrical insulation, and weather resistant qualities. Extreme temperature resistance makes EPDM useful for outdoor applications. It is frequently utilized in electrical cables, vehicle seals, and roofing systems.

Comparison: 1. Elasticity and Flexibility: In comparison to EPDM, modified PP,POE élastomère de polyoléfineoffers more flexibility and elasticity. It is perfect for applications that call for repetitive bending or stretching because of its low compression set, which guarantees that it can regain its original shape after deformation. However, EPDM may not be as elastic as modified PP, POE polyolefin elastomer while having considerable flexibility.

Both materials have strong chemical resistance, although modified PP, POE polyolefin elastomer has the advantage in this area. It is resistant to a greater variety of substances, such as acids, solvents, and oils, without significantly degrading. Although EPDM is also chemically resistant to a great extent, it could not be as adaptable as modified PP or POE polyolefin elastomer.

3. Weatherability: EPDM is a well-liked option for outdoor applications because of its outstanding weather resilience. It won’t degrade even after being exposed to sunshine, ozone, and high temperatures for an extended period of time. While modified PP, POE polyolefin elastomers are likewise well weatherable, they could not be as UV resistant as EPDM.

4. Price: Modified PP, POE polyolefin elastomer is often less expensive than EPDM in terms of price. This makes it a desirable alternative for producers seeking to lower manufacturing costs without sacrificing performance. Due of its strength and endurance, EPDM, while being slightly more costly, delivers outstanding value for money.

In conclusion, each of the three materials—modified PP, POE polyolefin elastomer, and EPDM—has distinct benefits and uses. While EPDM excels in weatherability and electrical insulation, modified PP, POE polyolefin elastomer excels in flexibility, elasticity, and chemical resistance. The exact requirements of the application and the required performance qualities ultimately determine which of the two materials is used.