The weather plummets in winter and the climate turns cold. Sub-zero temperatures appear in many cities, and manufacturers of plastic products in this low-temperature climate have encountered many problems. Recently, many customers have asked: the product usually has good toughness, but now the temperature drops in winter, the product is too brittle, and it cracks when it is lightly thrown on the ground for testing. Can this problem be solved?

As a material or product, it needs to adapt to environmental changes, but most nylon materials are brittle, that is, they become brittle after encountering low temperatures and are easily damaged. This is mainly due to the high crystallization tendency and high glass transition temperature of nylon resin. Therefore, it is of good practical significance to explore a reasonable preparation method to avoid the brittleness of nylon at low temperature.

So how to make nylon maintain its toughness at low temperatures?

Coace W1A gives you the answer

W1A is a maleic anhydride grafted POE elastomer, which has a low glass transition temperature and therefore has good low-temperature performance.

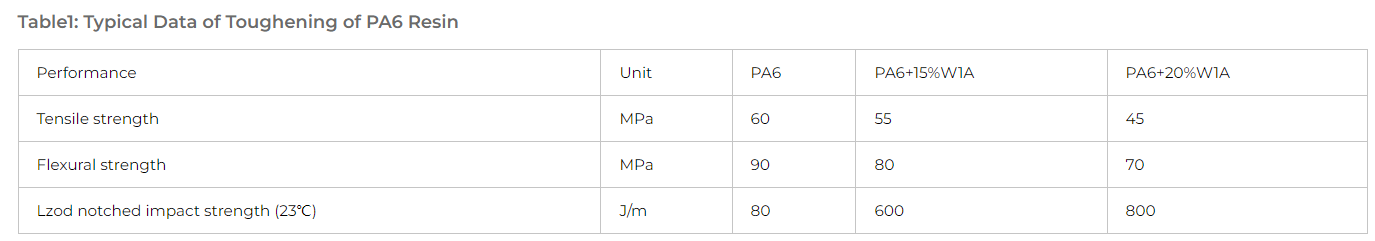

POE elastomers can still maintain good flexibility at low temperatures below −50˚C. POE elastomers are used as nylon The toughening agent can improve the low temperature impact resistance of nylon to a certain extent.

W1A not only has the good processability and excellent performance of POE, but also has the reactivity W1A not only has the good processability and excellent performance of POE, but also has the reactivity of MAH,

W1A not only has the good processability and excellent performance of POE, but also has the reactivity of MAH,

which can react with the polar groups in nylon molecules to improve the compatibility between W1A and nylon, thereby improving the mechanical properties of composite materials. performance.