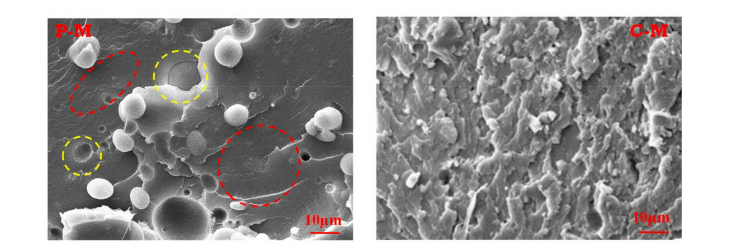

PM with 75:25 ratio of LDPE to ABS (physical mixing) and CM with 75:25:5 ratio of LDPE, ABS to MA (chemical mixing) were prepared by twin-screw extruder. The ABS used is a secondary material processed by physical means to improve the mechanical properties of PE.

PM showed two phases, ABS was scattered in the PE matrix, the yellow dotted circle showed obvious pits, indicating that ABS and PE were debonded under stress, and the red dotted line showed a smooth plane, indicating that there was no There is no ABS distribution there.

This all shows that the two phases of physically mixed PM cannot be well compatible.

The PM is a continuous rough surface, which shows that the compatibility between ABS and PE is very good, and it can play a reinforcing role.

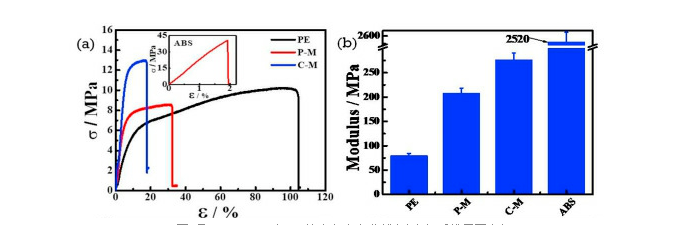

Figure 2 is the stress-strain curve (a) and Young’s modulus diagram (b) of PE, PM, CM and ABS, which are used to characterize the mechanical properties of the material.

It can be seen from Figure 2a that the ultimate fracture strength of CM is significantly greater than that of PM, and the ultimate fracture strength of PM is even lower than that of PE. This is because ABS improves the ultimate fracture strength of PE, but because ABS is not compatible in PM, The material has defects, which reduce the mechanical properties.

Figure 2b shows that the Young’s modulus of PE reinforced with ABS is significantly improved, and the improvement effect of CM is more obvious, which is also in line with the conclusion of the SEM image.