Modification of PE introduction

Ethylene monomer is used to create PE, a polymer. The surface of PE is inert and non-polar, which results in printability, dyeability, hydrophilicity, adhesion, antistatic characteristics, compatibility with other polar polymers, and inorganic fillers. PE has good mechanical processing qualities. Poor wear resistance, chemical resistance, cracking resistance to environmental stress, and heat resistance restrict its range of applications. Through alteration, enhance its functionality and broaden its application range.

Graft modification as a technique of PE material modification

graft modification

The grafted polymer hardly modifies the ethylene skeleton structure while simultaneously grafting polar monomers with different functionalities onto the PE main chain, maintaining the original properties of PE while also introducing new capabilities. A straightforward yet efficient technique for polar functionalizing PE.

Solution technique, melting method, solid phase method, and radiation grafting method are the major ways that grafting reactions are implemented.a

Solution technique, melting method, solid phase method, and radiation grafting method are the major ways that grafting reactions are implemented.

Solution technique Use a liquid phase reaction media, such as toluene, xylene, chlorobenzene, etc. The reaction media contains dissolved amounts of PE, monomer, and initiator, and the system is homogenous. The grafting process is greatly influenced by the medium’s polarity and the monomer’s chain transfer constant.

Solid-phase technique 2. For a reaction, the monomers, initiators, surfactants, etc. come into direct contact with the PE powder. The solid-phase method has a number of advantages over the conventional implementation method, including a suitable reaction temperature, normal reaction pressure, essentially maintaining the physical properties of the polymer without the need to recover the solvent, a straightforward post-treatment step, high efficiency, and energy savings.

3. Melting procedure Free radical copolymerization takes place in the presence of grafted monomers, and then grafted on the polymer macromolecular chains. In the molten state, the thermal breakdown of the initiator creates free radicals, starting the macromolecular chains to generate free radicals. chain sideways.

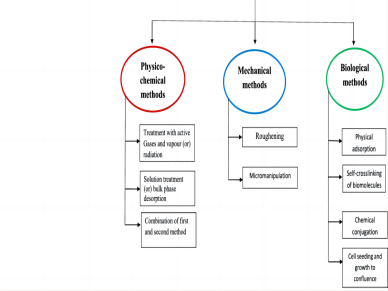

4. The use of radiation grafting Irradiation techniques including -rays, -rays, and electron beams are used to modify the surface of radiation-grafted materials. The idea is that after being exposed to radiation, polymers produce free radicals, which are then grafted with other monomers. Surface modification is accomplished by a polymerization process. The three basic techniques for modifying radiation grafting are peroxide, co-irradiation, and pre-irradiation.

Cross-linking alterations

The cross-linking modification dramatically increases PE’s physical and mechanical strength as well as its resistance to environmental stress cracking, corrosion, creep, and weather, which broadens the scope of its applications. One common use of PE crosslinking is in the marketed PEX (aluminum-plastic composite pipe). Radiation, chemical, and silane cross-linking are all types of cross-linking modification.

Radiation 1. Polyethylene enters a radiation field during crosslinking. High-energy rays (mostly gamma rays, X-rays, and electron beams, etc.) can cause a number of active particles to develop in solid polymers. These active particles then cause a number of chemical processes to occur, leading to the formation of a cross-linked three-dimensional network structure inside the polymer.

2. cross-linking with chemicals The unsaturated sites in PE molecules serve as active centers for the free radicals produced by the breakdown of peroxides or azo compounds. These active centers are bonded together by monomers to form chemically cross-linked polyethylene.

Silane crosslinking: After being grafted onto the PE main chain, silane containing unsaturated vinyl and readily hydrolyzable alkoxy polyfunctional groups is hydrolyzed and condensed into —Si—O—Si by the action of water and silanol.

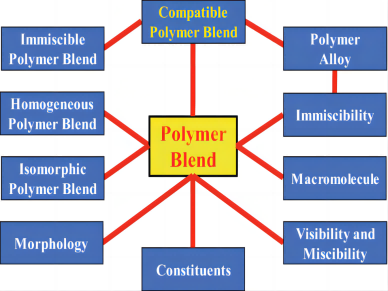

Polymerization blending

1. Modification of copolymerization Copolymerization modification of polyethylene includes coordination copolymerization, such as ethylene-propylene rubber (EPR), ethylene-propylene-diene rubber (EPDM) and copolymers of ethylene with 1-butene and 1-pentene; Free radical copolymerization of ethylene, such as ethylene-vinyl acetate copolymer (EVA); ionic copolymerization, such as ethylene-(meth)acrylic acid copolymer, ethylene-glyceryl methacrylate (EGMA) copolymer, etc. The macromolecular chain’s flexibility may be altered by the copolymerization procedure, or the original group may acquire a reactive functional group that can operate as a reactive compatibilizer.

2. Changing the blend To increase the toughness, impact resistance, printability, and oil barrier qualities of PE, additional resins, rubber, or thermoplastic elastomers are blended with it.

①Modification to the PE mix for high and low density. strong-density PE has strong strength and poor toughness, whereas low-density PE is soft and weak. Combining the two can create PE materials with a range of hardness by building on each other’s advantages. Due to the eutectic between LLDPE or VLDPE and HDPE, as well as a portion of the eutectic with LDPE, adding these materials to the HDPE/LDPE blend system will achieve the goal of boosting its performance.

②Blending adjustment for PE and CPE (chlorinated polyethylene). Chlorine atoms are added to the mixture after CPE and PE have been combined, which may enhance PE’s flame retardancy. By choosing a suitable compatibilizer, you may increase their compatibility and prevent the product’s performance from being harmed by other flame retardant techniques. The printability and hardness of PE can also be increased by the combining of PE with CPE.

③ Modification to combine PE and EVA . The combination of PE and EVA (ethylene-vinyl acetate) is highly regarded because of its great flexibility, transparency, superior air permeability, and printability. However, the product’s mechanical strength has also dropped.

④ Rubber and PE are blended modified. HDPE’s impact performance may be greatly enhanced by blending it with rubber materials (such as butyl rubber, natural rubber, styrene-butadiene rubber, ethylene-propylene rubber, etc.).

⑤Modification to the mixing of polyamide (PA) with PE. The barrier characteristics of PE to oxygen and hydrocarbon solvents can be improved by including PA. However, the compatibility between PA and PE is low because to the disparity in molecular structure. Through the use of UV light, Xu Xi and colleagues added polar groups such C=O, —COOH—, and —OH to the molecular chain of PE, which they then melted with PA. The procedure involves a chemical reaction between the inserted polar group and the amide or terminal amine group on the PA molecular chain, which improves the interfacial contact between HDPE and PA.

Filling amendment

In order to minimize the cost of raw materials for plastic goods, achieve the goal of weight gain, or drastically alter the performance of plastic products, filling modification involves adding inorganic particles into the thermoplastic resin matrix. Some performances are compromised, whereas others are much enhanced.

The filling adjustment is separated into general filling and functional filling for discussion’s sake.

1. alterations to general filling General filling is restricted to modifications to PE’s mechanical characteristics. Calcium carbonate, talc, kaolin, barium sulfate, calcium silicate, and silicon dioxide are examples of inorganic fillers used to fill PE. PE composite material with calcium carbonate filler can lower product costs while enhancing stiffness, heat resistance, and dimensional stability. However, there is poor interface adhesion between the non-polar high polymer PE and the inorganic filler calcium carbonate, which lowers the material’s mechanical and flow characteristics. By including a coupling agent or covering calcium carbonate with MPEW (maleic anhydride grafted polyethylene oligomer), interfacial adhesion can be strengthened. For filling PE, common organic fillers include fiber from wood powder, straw, etc.

2. Modification of the functional filling Functional filling refers to filling modifications that improve the effects of plastics on light, electricity, magnetism, combustion, etc. rather than only altering their mechanical characteristics. Biodegradable polyethylene, conductive polyethylene, and flame-retardant polyethylene are all examples of functional filled polyethylene.

①Biodegradable plastic: After subjecting PE to the denaturation process, starch can be added to create starch plastic. Because it contains starch, it can be microbially degraded once it has been buried in the soil. Studies have demonstrated that PE/starch degradable plastics may be eroded by microbial secondary metabolites in addition to being directly utilized as a carbon source by microorganisms.

②Conductive polyethylene: New functional materials that are conductive can be created by combining insulating polyethylene resin with conductive fillers (such carbon black, metal powder). This type of material has significant theoretical research value and a wide range of potential applications, including antistatic, conductive, free control surface heating, electromagnetic shielding, etc.

③Polyethylene that resists flames: The PE flame-retardant techniques are: ①Combine halogen flame retardants with antimony trioxide and employ them. ②Add tribromobenzene, organic acid, and ammonium phosphate, for example. ③Incorporate flame-resistant inorganic fillers like Al(OH), Mg(OH), and others.

Improved modification

Reinforcement modification is the term used to describe the filling modification with reinforcement effect. The reinforcement materials chosen for this modification include glass fiber, synthetic fiber, whisker, etc. Self-reinforcing modification is also included in this category for discussion’s sake.

change that reinforces itself. In this improved modification, no filler material is added; instead, the flow velocity gradient of the PE melt is increased through a special molding processing method and a specially designed mold flow channel, resulting in a parallel orientation of the molecular chains that is beneficial for straightening. chain crystals to fully use the material’s intrinsic potential and create polyethylene products with mechanical qualities similar to engineering plastics. There is no need to take into account the compatibility of polyethylene and filling materials because no filler is used.

Modified polyethylene reinforced with glass fiber. PE may be reinforced with inexpensive, easily accessible high-strength glass fiber to increase its mechanical strength and heat resistance, converting it to an engineering plastic. According to research findings, the glass fiber surface and its silane can chemically interact or cross-link with the addition of interfacial reaction reagents and the grafts made by grafting with PE during the composite process, which can significantly improve the interfacial bonding performance and mechanical properties of the composite material.

Since they are less thick and more powerful than glass fibers, synthetic fibers can also be employed as reinforcing fillers. Polyacrylonitrile, polyamide, polyvinyl alcohol, and aromatic polyamide are examples of synthetic fibers that can be used to modify PE.

With their benefits of high strength, high modulus, strong thermal insulation performance, etc., and good compatibility with the matrix, whiskers are a novel type of material that may also be utilized as a reinforcing agent. Whiskers made of calcium carbonate, potassium titanate, and other materials are frequently utilized.

PE has been altered by nanoparticles.

Materials having an average particle size below 100 nm and a particle size at the boundary between atomic clusters and macroscopic objects are referred to as nanomaterials. Nanoparticles exhibit a variety of unique physical and chemical characteristics as a result of surface effects, volume effects, etc. With good mechanical, optical, electrical, and magnetic characteristics, polymer-based polymer/inorganic nanoparticle composites can produce significant The horizon of material science research is the development of multifunctional new materials through the nanoscale modification of polymers.

Nanomontmorillonite modified PE, nanozinc oxide modified PE, nanoalumina modified PE, and nanoclay modified PE are some examples of nano-modified PE materials.

uses of modified PE materials downstream

Used as filler for PP, PE transparent film, milky white film, and colorful film in pe modified plastic blown films.

PE modified plastic injection molding: utilized for PP, PE high-grade clear injection molding, home appliances, electrical items, bathroom flooring, sporting goods, tableware, hand tools, toys, stationery, shoe materials, daily necessities, and medical equipment, among other things. Fillers for goods of various colors

Filling materials for hollow blow bottles of different daily-use containers: PE modified plastic blow molding

Extruding different roll film inner tubes, PP black tubes, fillers for other plastic water pipes, wires and cables, building materials, etc. are all examples of extrusion molding of pe modified plastics.

PE modified plastic woven bag filler for drawing molds

Filler for recycled pellets of PE-modified plastic