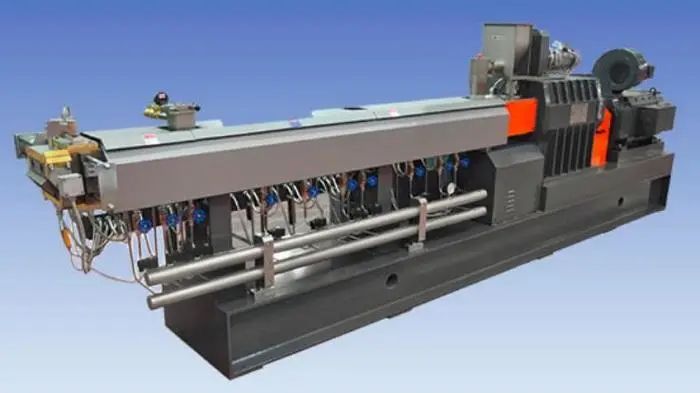

Starting from this section, I will tell you about an understanding of threaded components by category. Let’s take the most common model called 65 machine as an example to talk about a major category of threaded components called conveying blocks.Here are four key points to share with you.

01Conveyor block type

For the 65 machine type, there are several different types of conveyor blocks, such as 96/96, 72/72, 64/64, 56/56, 44/44 and 22/22. Also with L, there will probably be several types of conveyor blocks.

02 Conveyor block difference

The second point, let me tell you the difference. Usually, the larger the number, the longer the length and the larger the lead. The better the conveying capacity is, if the number is small, such as 96 and 44, it is obvious that the conveying capacity of 44 is definitely not as good as 96, but it can compress the material, so the ability to compress the material is better.

03 reverse threaded element

The third point is that there is also a threaded element such as 22/22, which has an L behind it. Usually it is a reversed threaded element. When it is pushed forward, it reaches this 22/ 22L, it flows back in the opposite direction. Usually, this threaded element will be used at the junction of the previous section of the exhaust port or the vacuum port to increase the pressure of the corresponding cylinder, and then the pressure will be instantaneous when it reaches the exhaust port. It can be lowered so that it can exhaust better, and there will be no leakage during the exhaust process.

04 Conveyor block difference

The fourth point, all the conveying blocks have several different ways, such as single head, multi head and double head. Usually, what we use is mainly double head. The main function of single head is that the conveying capacity is particularly good, and then The gap between it and the barrel is also very small, so we usually use this threaded element at the end of the barrel of the extruder, that is, near the die, to improve the extrusion die. One pressure, what is the use of the three heads generally, because there are deep grooves and shallow grooves in the twin-screw, usually a screw with shallow grooves, because it needs to be designed with shallow grooves, so it will send the threaded elements, that is, convey Block will design it as a structure with three heads, so that its extension becomes shallower.