A potent polymer addition known as PE-g-MAH (Polyethylene-grafted-Maleic Anhydride) has evolved, revolutionising the capabilities of polyethylene (PE) products across a variety of sectors. PE-g-MAH presents a variety of options for producers looking to improve performance and sustainability thanks to its broad application range, numerous functionalities, durability, and environmental advantages. In this paper, we examine the many PE-g-MAH applications and emphasise the benefits of various grafting techniques, emphasising the importance of these techniques in actual industrial production.

Wide Range of Applications: PE-g-MAH is used in a wide range of sectors, including consumer products, construction, packaging, and automotive. It adds value to the production of automotive components, packaging, pipelines, and long-lasting consumer items by improving adhesion, compatibility, and processability. Because of its adaptability to the demands of various industries, PE-g-MAH is a crucial instrument for enhancing the performance of products.

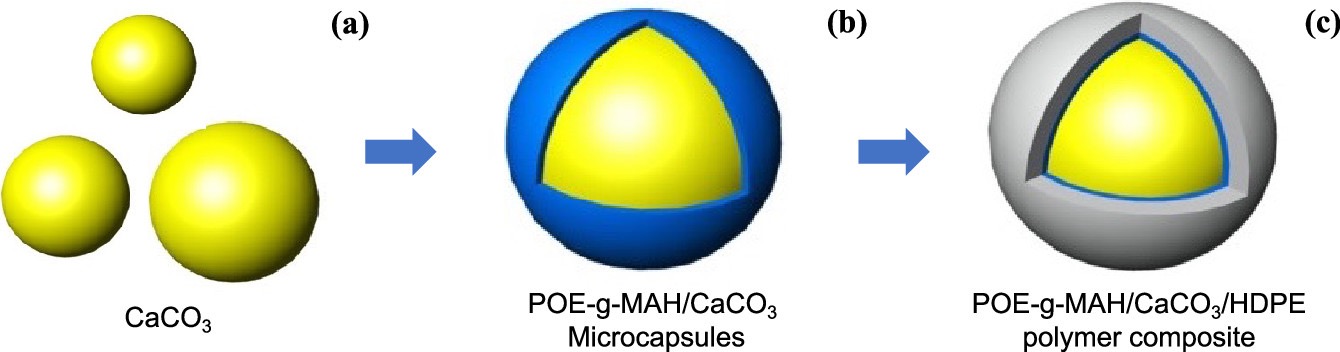

Multiple Uses and Durability: PE-g-MAH has a surprising degree of adaptability and may be used for a variety of purposes when added to polyethylene. It considerably enhances adhesion to many materials, including metals and polar substrates, by the grafting of maleic anhydride. In the automobile sector, where strong adhesion between plastic and metal parts is essential, this feature is extremely helpful. Additionally, PE-g-MAH improves mechanical strength, impact resistance, and thermal stability to guarantee that items are robust and long-lasting.

Environmental Protection: As sustainability becomes more significant, PE-g-MAH helps to safeguard the environment by minimising waste and encouraging eco-friendly behaviours. It decreases the need for frequent replacements and increases the longevity of polyethylene goods, enhancing their qualities and decreasing waste formation. Maleic anhydride is also added to polyethylene to improve its capacity to be recycled, leading to more effective recycling procedures. PE-g-MAH's eco-friendliness is in line with the rising need for sustainable production.

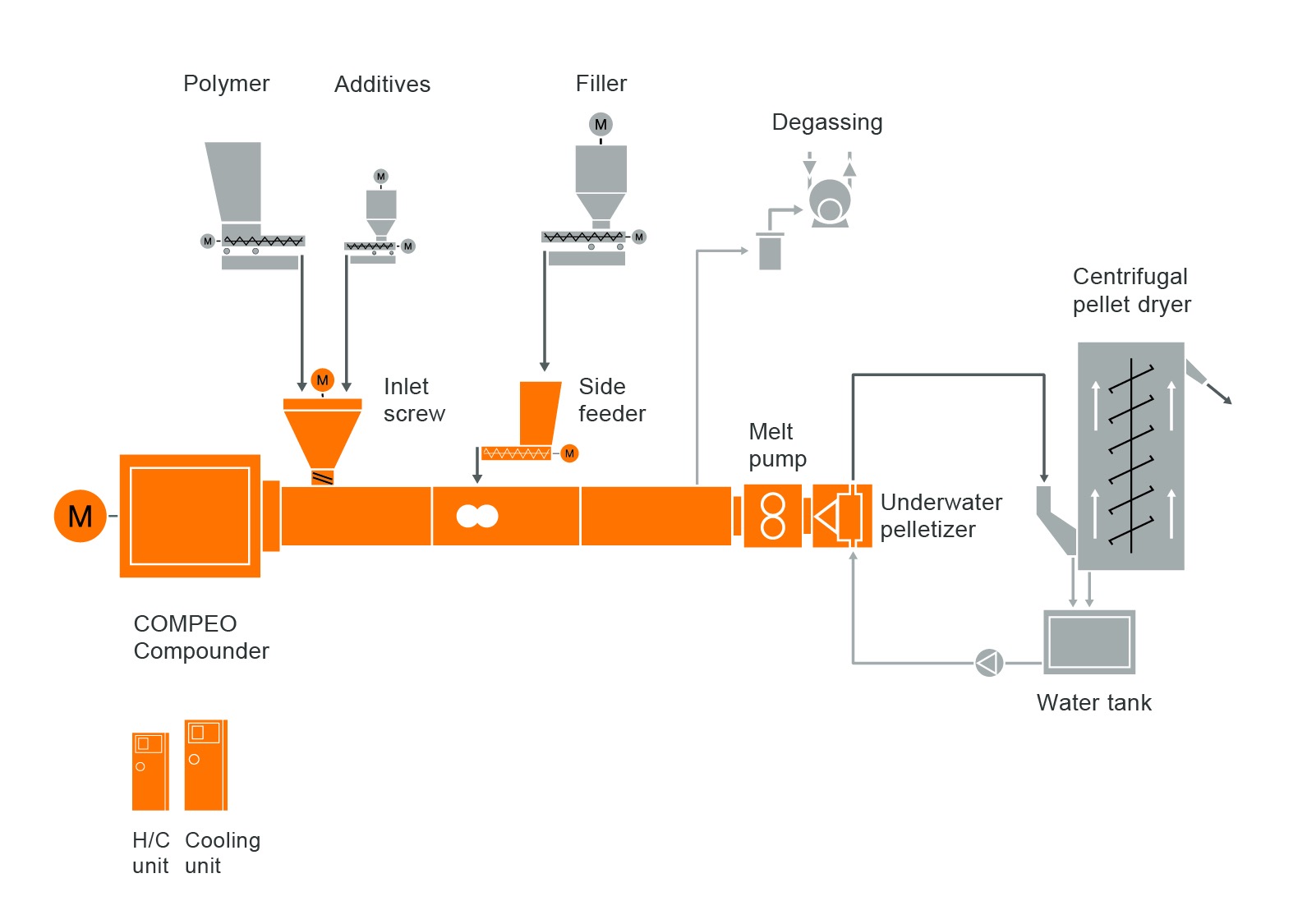

Various Grafting Methods: Maleic anhydride is used in PE grafting using a variety of techniques, including solution, melting, solid-phase, solid-phase mechanochemical, photographing, and suspension procedures. These techniques are adaptable and meet various application needs. One technique that works well for large-scale manufacturing is the solution method, which is renowned for its quick reaction time and continuous operation. The solid-phase mechanochemical approach uses less energy and reaction time. Based on unique production requirements, manufacturers may choose the best grafting technique, maximising productivity and efficiency.

Industrial Production Advancements: The benefits of PE-g-MAH, such as its broad application range, numerous functions, and durability, have been extensively used in actual industrial production. Automotive and packaging industries, among others, have effectively incorporated PE-g-MAH to improve product performance and accomplish desired results. These productive applications demonstrate the efficiency and dependability of PE-g-MAH in actual industrial settings.

PE-g-MAH opens up a wide variety of application options, numerous functionalities, durability, and environmental advantages for polyethylene goods. It improves the functionality and sustainability of goods across several sectors as an essential polymer ingredient. With a variety of grafting techniques available, producers have the freedom to select the best strategy for their unique manufacturing needs. PE-g-MAH will be essential in fostering innovation as the market for high-performance, environmentally friendly materials expands. This will allow businesses to produce better goods while advancing green manufacturing techniques.