01 Characterization of the toughness of plastics

Toughness, as opposed to rigidity, is a quality that represents how challenging it is to deform an item. The likelihood of deformation decreases with increasing rigidity, but deformation is made simpler with increased toughness. In general, a material's rigidity determines its hardness, tensile strength, Young's modulus, flexural strength, and flexural modulus; conversely, a material's toughness determines its elongation at break and impact strength. big. Impact strength is the ability of a spline or workpiece to survive an impact; it often refers to the amount of energy that the spline can take before breaking.

Impact strength cannot be categorized as a fundamental attribute of the material since it varies based on the spline's form, the testing procedure, and the state of the test sample.

Impact tests can be done in a variety of ways. There are three different types of impact tests depending on the test temperature: normal temperature impact, low temperature impact, and high temperature impact. Additionally, depending on the sample's stress state, there are four different types of impact tests: bending impact (including cantilever beam and charpy impacts), tensile impact, torsional impact, and shear impact. Cutting impact may be split into two categories: single impacts with high energy and many impacts with low energy, depending on how many impacts are made. Different impact test techniques can be chosen for various materials or applications, leading to a variety of findings that cannot be compared.

02 Plastic toughening mechanism

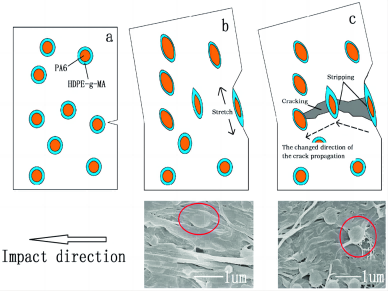

There are two types of plastic toughening: rigid toughening agent toughening and flexible toughening agent toughening. The theories of direct energy absorption by elastomers, yield, crack core, multiple craze, craze-shear band, craze branching, Wu's theory, etc. are examples of the toughening mechanism. The craze-shear band hypothesis is one of those that has gained a lot of acceptance since it can satisfactorily explain a number of experimental data.

The craze-shear band hypothesis states that rubber particles primarily play two roles in the rubber-toughened plastic mix system:

Por un lado, provoca muchas grietas y bandas de cizallamiento en la matriz como lugar de concentración de tensiones;

Por otro lado, se puede evitar que las grietas se conviertan en fracturas destructivas limitando su capacidad de propagación.

Las bandas de cizallamiento pueden ser inducidas por el campo de tensión hacia la conclusión del frenesí para detenerlo. Además, detiene el crecimiento de las grietas cuando entran en la zona de cizallamiento. Se utiliza energía durante la formación y el crecimiento de muchas grietas y bandas de cizallamiento cuando el material está sometido a tensión, lo que aumenta la tenacidad del material. El shear banding se asocia con la formación de cuellos estrechos, mientras que el craze se muestra macroscópicamente como un evento de blanqueamiento por tensión. Estos dos fenómenos tienen comportamientos distintos en diversos sustratos plásticos.

03 Contributing factors to the plastic toughening impact

1. Características de la resina matriz

According to studies, increasing the matrix resin's hardness will also increase the toughening effect of toughened plastics. The following methods may be used to increase the matrix resin's toughness: managing crystallization and crystallinity, crystal size and shape, etc.; raising the matrix resin's molecular weight to narrow the molecular weight distribution. For instance, adding a nucleating agent to polypropylene (PP) speeds up crystallization and refines the grain structure, increasing the material's fracture toughness.

2. Dosis y características del agente endurecedor

A. The toughening agent's dispersed phase's particle sizeThe qualities of the matrix resin and the ideal value of the particle size of the elastomer's dispersion phase are different for elastomer-toughened plastics. For instance, the ideal rubber particle size in HIPS is between 0.8 and 1.3 m, the ideal ABS particle size is around 0.3 m, and the ideal PVC-modified ABS particle size is roughly 0.1 m.

B. Toughener glass transition temperature – the toughening effect is improved when the glass transition temperature of general elastomers is lower;

C. The interfacial binding strength between the toughening agent and the matrix resin, which affects the toughening effect differently depending on the system;

D. The structure of elastomer tougheners, which depends on the kind of elastomer, the degree of crosslinking, etc.

E. The amount of toughening agent – the particle distance parameter is connected to the ideal amount of toughening agent supplied;

3. La fuerza que une las dos fases

The macroscopically higher overall performance of the plastic is mostly due to the gain in impact strength, but a good bonding force between the two phases can also make it possible for stress to be successfully conveyed between the phases while using more energy. This binding force is typically thought of as the interaction between two phases. Block and graft copolymerization are frequent techniques for enhancing the bonding force between two phases. The distinction is that they create chemical linkages using techniques like grafting and block copolymerization. HIPS, ABS, SBS, and PUR are examples of block copolymers.

Pertenece a la categoría de mezclas físicas para polímeros endurecidos, pero la idea básica es la misma. Los dos componentes deben ser en cierto modo compatibles y crear sus propias fases en el mecanismo de mezcla ideal. Entre las fases hay una capa de interfaz. Las cadenas moleculares de los dos polímeros' se difunden entre sí en la capa de interfaz, y el gradiente de concentración es claro. A medida que se intensifica la mezcla, la compatibilidad de los componentes da lugar a una fuerte fuerza de unión, que posteriormente mejora la difusión para dispersar la interfase y espesar la capa de interfase. La tecnología crucial para crear aleaciones de polímeros en este punto es la tecnología de compatibilidad de polímeros, ¡que también incluye el endurecimiento del plástico!

04 What are the techniques for toughening plastic?

EPR (ethylene propylene diene), EPDM (ethylene propylene diene), butadiene rubber (BR), natural rubber (NR), isobutylene rubber (IBR), nitrile rubber (NBR), etc. are examples of toughened rubber elastomers. All plastic resins may be modified to become tougher using this method.

2. SBS, SEBS, POE, TPO, TPV, etc. are toughened using thermoplastic elastomers. It is mostly used to toughen polyolefins or non-polar resins; when used to toughen polymers with polar functional groups, such as polyesters and polyamides, a compatibilizer should be added.

3. Strengthening of reactive terpolymers and core-shell copolymers

ACR stands for "acrylates," MBS for "methyl acrylate-butadiene-styrene copolymer," PTW for "ethylene-butyl acrylate-glycidyl methacrylate copolymer," and so on. The majority of its applications are to toughen technical plastics and high temperature resistant polymer alloys.

4. Toughening and mixing of high-tensile plastic

PC/ABS, PC/PBT, HIPS/PPO, PP/PA, PP/ABS, PA/ABS, PPS/PA, etc. Engineering plastics with high toughness may be made in large part through the use of polymer alloy technology.

5. Additional toughening techniques

Sarin resin (a DuPont metal ionomer) toughening, nanoparticle toughening (using nano-CaCO3, for example), etc.

La polimerización por adición de radicales libres suele utilizarse para producir polímeros de uso general. Las cadenas laterales y la cadena principal de la molécula carecen de grupos polares. Los plásticos técnicos pueden endurecerse añadiendo partículas de caucho y elastómeros para conseguir un mayor efecto endurecedor. Normalmente, se utiliza la polimerización por condensación para crearlo. Los grupos polares se encuentran en la cadena lateral o en el grupo terminal de la cadena molecular. Puede hacerse más resistente utilizando partículas de caucho o elastómero funcionalizadas.

05 How to comprehend that capacity must be increased before toughening

En general, cuando se exponen a fuerzas externas, los plásticos absorben y liberan energía a través de los procesos de desprendimiento de la interfaz, cavitación y cesión por cizallamiento de la matriz. Los elastómeros con alta compatibilidad, a excepción de las resinas poliméricas no polares, pueden aplicarse directamente. Para alcanzar el objetivo de endurecimiento final cuando se utilizan partículas (mismo principio de compatibilidad), otras resinas polares deben compatibilizarse con éxito. Los copolímeros de injerto indicados anteriormente interactuarán fuertemente con la matriz cuando se utilicen como endurecedores, incluyendo:

(1) La reacción de adición entre el grupo funcional epoxi y el grupo hidroxilo, carboxilo o amina terminal del polímero tiene lugar tras la apertura del anillo.

(2) Mecanismo de endurecimiento del núcleo: el caucho tiene un efecto endurecedor mientras que el grupo funcional exterior es totalmente compatible con los componentes;

(3) Mecanismo de endurecimiento del ionómero: La red de reticulación física se crea cuando los iones metálicos y los grupos carboxilato de las cadenas poliméricas forman un complejo que endurece el material.

In reality, this compatibilization approach may be applied to all polymer blends if the toughener is thought of as a class of polymers. Reactive compatibilization is a method we must employ when creating practical polymer blends for industry. The term "toughening agent" now refers to a "interfacial emulsifier" or "toughening compatibilizer," respectively. The name is quite expressive!