Descripción de los productos

W1H is a general-purpose HDPE-G-MAH product with excellent comprehensive properties. It contains maleic anhydride and has strong plasticity, which can improve the properties of polymerization and matrix minerals, and the surface roughness of inorganic substances, reaching The effect of enhancing the strength of composite materials.

By enhancing compatibility, mechanical characteristics, and processability in polymer blends, the Universal HDPE-G-MAH Compatibilizer for Polyolefin Materials provides outstanding value and performance. This compatibilizer transforms the compatibility and performance of polyolefin blends with its distinctive HDPE-G-MAH structure, improved interfacial adhesion, and broad range of application compatibility. Buyers in a variety of industries, such as consumer products, packaging, construction, and automotive, can gain improved compatibility, excellent mechanical qualities, a wide processing window, and cost-effectiveness by integrating this compatibilizer into their manufacturing processes. The compatibilizer is a highly attractive option for producers looking to improve cost-effectiveness, compatibility, and performance in polyolefin blend applications because of its remarkable features and benefits.

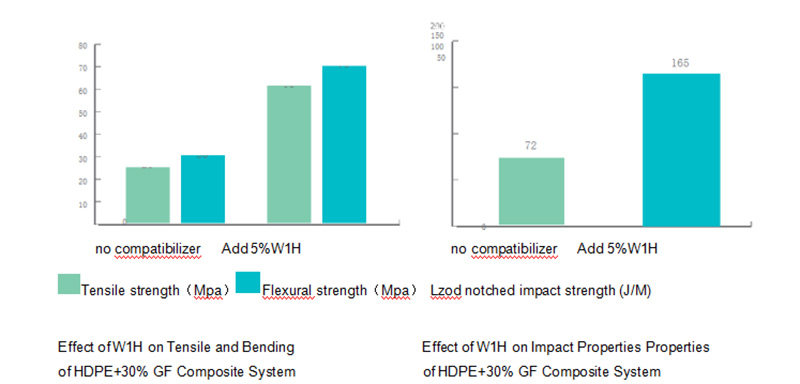

Application effect of W1H in glass fiber (30%) reinforced HDPE:

Nota:HDPE raw material uses DOW K T 10 0 0, glass fiber uses Jushi 98 8 A

It can be seen from the figure that in the 30% glass fiber reinforced HDPE system, adding 5% Kolibang®W1H can greatly improve the tensile strength, bending strength and notched impact strength of the material system, and the coupling effect is remarkable.

Equipamiento avanzado

Equipada con avanzadas líneas de producción y centro de pruebas experimentales para garantizar la calidad del producto.

Gran fuerza técnica

Más de 10 técnicos experimentados en I+D impulsan la innovación continua.

recomendación Asistencia técnica Protección posventa

Característica

| Elementos de prueba | Datos de la prueba | Método de detección |

| densidad | 0,95 g/cm³ | ASTM D792 ISO 1183 |

| punto de fusión | 130℃(266℉) | ASTM D3418 ISO 3146 |

| Derretir dedo | 1-3(190℃,2.16kg)g/10min | ASTM D1238 ISO 1133 |

| Porcentaje de injertos | Alta | valoración ácido-base |

| Exterior | partículas |

W1H es un producto de HDPE-G-MAH de uso general con excelentes propiedades integrales.

- HDPE-G-MAH Structure: The compatibilizer is made of high-density polyethylene (HDPE) with a grafted maleic anhydride (MAH) structure connected to the backbone. The compatibility and interfacial adhesion of different polyolefin materials in blends are improved by this special structure.

- Enhanced Interfacial Adhesion: Polyethylene (PE) and polypropylene (PP), two incompatible polyolefin materials, are made to adhere to one another more strongly by using the HDPE-G-MAH compatibilizer. By establishing a compatible interface, it lessens phase separation and enhances the mechanical characteristics of blends of polymers.

- Better Thermal resilience: The compatibilizer can tolerate high processing temperatures without degrading because of its outstanding thermal resilience. This feature guarantees compatibility and reliable performance across a range of manufacturing methods.

- Flexible Application Compatibility: A broad variety of polyolefin materials, such as PE and PP, and their different grades, are compatible with the Universal HDPE-G-MAH Compatibilizer. Because of its adaptability, it can be integrated into a variety of polymer systems to provide specialized solutions for certain application needs.

Ventaja

- Improved Compatibility: By considerably enhancing the compatibility between various polyolefin materials, the HDPE-G-MAH compatibilizer makes it possible to create polymer blends with uniform structures and better mechanical qualities. It improves interfacial adhesion, minimizes phase separation, and maximizes the performance of the finished product.

- Better Mechanical Properties: The compatibilizer makes polyolefin blends have better mechanical properties by lowering phase separation and increasing interfacial adhesion. More elongation at break, impact resistance, and tensile strength are increased, making the products stronger and longer-lasting.

- Extrusion, injection molding, blow molding, and other production processes are all supported by the compatibilizer’s large processing window, which is made possible by its exceptional temperature stability and varied compatibility. It offers producers adaptability and processing simplicity in a range of production settings.

Nuestra ventaja

Cadena mundial de suministro

Sistema de cadena de suministro de almacenamiento y logística

Asistencia técnica

Protección posventa

Concentración - Logro - Excelencia

Productos a medida

Centrarse en la I+D

Servicios globales

Certificación Coace

Certificación ISO9001:2015

Certificación ISO14001:2015

Registro REACH de la UE

Preinscripción en K-REACH de Corea

Ventaja empresarial

Disposición en el país y en el extranjero, maravillosa para mezclar

Distribución nacional

Diseño de marketing en el extranjero

Aplicación

1. Puede utilizarse como compatibilizador para materiales de cables ignífugos sin halógenos de baja emisión de humos;

1. Puede utilizarse como compatibilizador para materiales de cables ignífugos sin halógenos de baja emisión de humos;2. Puede utilizarse como mejorador de la superficie de chapas/placas extruidas, que puede mejorar eficazmente la planitud de la superficie del material y eliminar las irregularidades y picaduras en la superficie del material;

3. Puede utilizarse como compatibilizador de polietileno y fibra de vidrio para promover la compatibilidad del polietileno y la fibra de vidrio;

4. Puede utilizarse como compatibilizador para masterbatches con PE como soporte, como masterbatches de color, masterbatches ignífugos, masterbatches funcionales, etc;

5. Puede utilizarse como modificador para prolongar el periodo antivaho del mantillo antivaho.