Descripción de los productos

When used as a chemical addition for polymer modification, the Maleic Anhydride SEBS Copolymer Toughening Agent provides outstanding value and effectiveness. This toughening agent allows polymers to reach their maximum potential because of its maleic anhydride modification, compatibility with SEBS copolymers, toughening action, and compatibility with a variety of polymers.Maleic Anhydride SEBS Copolymer Toughening Agent can be added to formulations to improve toughness, durability, energy absorption efficiency, and adaptability for a range of applications in consumer goods, automotive, electronics, and packaging.

Equipamiento avanzado

Equipada con avanzadas líneas de producción y centro de pruebas experimentales para garantizar la calidad del producto.

Gran fuerza técnica

Más de 10 técnicos experimentados en I+D impulsan la innovación continua.

Typical Data of Toughening of PA6 Resin

| Rendimiento | Unidad | PA6 | PA6+15%W1G | PA6+20%W1G |

| Resistencia a la tracción | MPa | 60 | 51 | 45 |

| Resistencia a la flexión | MPa | 90 | 73 | 67 |

| Lzod notched impact strength | J/m | 80 | 650 | 820 |

It can be seen from the above table that W1G has a good effect in nylon toughening and can greatly improve the toughness of nylon.

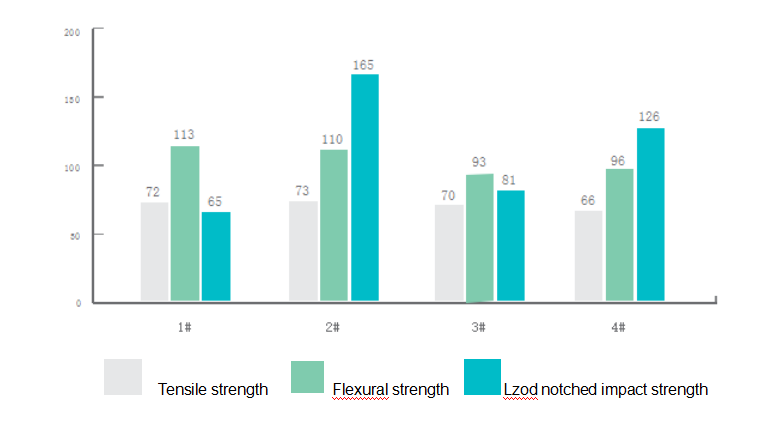

Typical data for PA/PPO alloys

| Formula | 1#(%) | 2#(%) | 3#(%) | 4#(%) |

| PA6-3280 | 25 | ⸺ | 30 | 60 |

| PPA66-EPR27 | 65 | ⸺ | ⸺ | |

| PPO | 60 | 20 | 50 | 45 |

| CS-1 (PP0 Compatibilizer) | 10 | 10 | 15 | 15 |

| W1G (toughening agent) | 5 | 5 | 5 | 5 |

| Silicone powder | 0.5 | 0.5 | ⸺ | ⸺ |

| PETS | ⸺ | ⸺ | 0.3 | 0.3 |

From the above table, it can be easily seen that the PW1G/PO alloy can improve the flexibility of the product on PA, and the product is easier to carry forward.

Característica

| Elemento de prueba | Datos de la prueba | Método de ensayo |

| densidad | 0.91 g/cm³ | ASTM D792 ISO 1183 |

| Índice de fusión | 2-9 (190℃,50kg) g/10min | ASTM D1238 ISO 1133 |

| Porcentaje de injertos | Medio | valoración ácido-base |

| Apariencia | blanco o amarillo claro Granulado |

W1G is a maleic anhydride grafted polymer. SEBS elastomer is used as the base material. The product has good fluidity, good temperature resistance and aging resistance.

- Maleic Anhydride Modification: To strengthen its chemical linkages with the polymer matrix, maleic anhydride is added to the toughening agent. By improving the toughening agent and polymer’s compatibility and interfacial adhesion, this change allows for more uniform dispersion and better mechanical characteristics.

- The toughening agent is formulated using the styrene-ethylene/butylene-styrene (SEBS) copolymer, which has remarkable compatibility with an array of polymer matrices. It guarantees even dispersion and effective mixing throughout the polymer, which enhances its toughness and resistance to impacts.

- Toughening Effect: Polymers’ toughness and impact resistance are greatly increased by the Maleic Anhydride SEBS Copolymer Toughening Agent. The process of energy absorption and dispersion during deformation lessens the likelihood of crack propagation and improves the material’s resistance to impact and dynamic stress.

- Compatibility with a Wide Range of Polymers: The toughening agent shows compatibility with engineering plastics, ABS, polypropylene, polyethylene, and polystyrene, among other polymer matrices. It provides flexibility and adaptability, enabling the creation of unique solutions to satisfy certain performance standards.

Ventaja

Increased Toughness: Polymers become more resilient when the Maleic Anhydride SEBS Copolymer Toughening Agent is included. It produces materials that can endure demanding applications and difficult environments by improving the impact resistance, tensile strength, and elongation at break.

Increased Durability: Polymer products have increased durability thanks to the toughening ingredient. It guarantees the modified polymers’ long-term performance and dependability by lowering the chance of cracking, delamination, and deformation.

Effective Energy Absorption: By effectively absorbing and distributing energy during deformation, the toughening agent lowers the chance of stress concentration and crack propagation. It improves the material’s resistance to impact and dynamic loading, making it appropriate for uses where strong impact resistance is needed.

Versatile Uses: The Maleic Anhydride SEBS Copolymer Toughening Agent is used in a wide range of fields and sectors, such as consumer products, automotive, electronics, and packaging. Because of its adaptability, various polymers can be altered to satisfy particular performance needs.

Nuestra ventaja

Cadena mundial de suministro

Sistema de cadena de suministro de almacenamiento y logística

Asistencia técnica

Protección posventa

Concentración - Logro - Excelencia

Productos a medida

Centrarse en la I+D

Servicios globales

Certificación Coace

Certificación ISO9001:2015

Certificación ISO14001:2015

Registro REACH de la UE

Preinscripción en K-REACH de Corea

Ventaja empresarial

Disposición en el país y en el extranjero, maravillosa para mezclar

Distribución nacional

Diseño de marketing en el extranjero

Aplicación

1. Elastomer modification such as TPE/TPR can be used for encapsulating nylon, etc.

2. Engineering plastics toughening agent compatibilizer

3. Asfalto modificado

4. Adhesive