Presently, maleic anhydride is typically grafted onto improved compatibilizers. Maleic anhydride monomer has more polarity and a superior compatibilization impact when compared to other monomers.

By adding potent polar reactive groups, the maleic anhydride grafted compatibilizer increases the material's polarity and reactivity. It is a type of dispersion accelerator, compatibilizer, and polymer interfacial coupling agent. It is mostly used as a halogen-free filler, to reinforce glass fibre, to toughen, to bond metal, to determine alloy compatibility, etc. It can significantly increase filler dispersion and composite material compatibility, increasing the mechanical strength of the latter.

Maleic Anhydride Grafting Benefits

1. Enhanced Mechanical Characteristics

The mechanical characteristics of polymer blends can be greatly enhanced by maleic anhydride grafting. This is due to the fact that it forges a solid link between the various polymers, increasing the material's resistance to strain and deformation. This can be especially helpful in situations when the material will be put under a lot of pressure or stress.

2.Improved Thermal Stability

Grafting with maleic anhydride can help increase the thermal stability of polymer mixtures. This is because it makes the distribution of the various polymers more uniform, which lessens the possibility of thermal deterioration. In industries like the automotive or aerospace, where the material will be subjected to high temperatures, this can be especially helpful.

3. Enhanced Operation

Grafting with maleic anhydride can help enhance the processing of polymer mixtures. This is due to the fact that it can decrease the material's viscosity, making it simpler to process and mould. Additionally, it can enhance the material's flow characteristics, which might lessen the likelihood of flaws and raise the general calibre of the final product.

4. Affordable

Maleic anhydride grafting is an economical method for enhancing the qualities of polymer blends. This is due to the fact that it is a pretty easy operation that can be completed utilising common tools. Additionally, because only modest amounts of the grafting agent are needed, it is a financially advantageous choice for mass production.

5. Flexibility

Maleic anhydride grafting is a flexible technique that works with a variety of polymers. As a result, a variety of materials, including thermoplastics, thermosets, and elastomers, can have their qualities enhanced. It is a popular choice for a variety of applications due to its versatility.

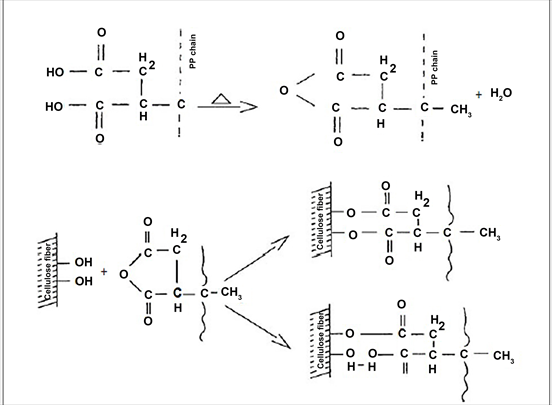

The Process of Maleic Anhydride Grafting

The various polymers in a mix are joined chemically through maleic anhydride grafting. Maleic anhydride is reacted with one of the polymers in the mixture to achieve this. A graft copolymer, which has maleic anhydride molecules linked to the polymer backbone, is produced when the maleic anhydride reacts with the polymer.

The maleic anhydride molecules serve as a compatibilizer, enhancing the bonding between the various polymers in the mixture. As a result, the distribution of the various polymers becomes more uniform, which enhances the material's general characteristics.

Applications:

(1) Filled with materials such as glass fibre, nylon, talcum powder, titanium dioxide, barium sulphate, calcium carbonate, and magnesium hydroxide.

(2) Toughening agent for PET, PBT, and PA.

(3) Alloy compatibilizer for PP/PA, PC/ABS, PC/PBT, ABS/PBT, and PS/PBT.

Maleic anhydride grafting applications

There are numerous uses for maleic anhydride grafting, including:

1. The Automotive Sector

In the automobile sector, maleic anhydride grafting is utilised to enhance the qualities of polymer blends used in interior and exterior components. Included in this are parts like bumpers, dashboards, and door panels.

2. The Packaging Sector

The packaging industry uses maleic anhydride grafting to enhance the characteristics of polymer blends used in food packaging and other applications. Components including films, trays, and containers are included in this.

3. The Construction Sector

In the building sector, maleic anhydride grafting is used to enhance the qualities of polymer blends used in building components like pipes, fittings, and insulation.

4. The Electronics Sector

In the electronics sector, maleic anhydride grafting is used to enhance the characteristics of polymer mixes used in electronic components such connectors, housings, and circuit boards.

Conclusión

Injerto de anhídrido maleico is a flexible and affordable method for enhancing the qualities of polymer mixtures. In comparison to other kinds of compatibilizers, it has a variety of benefits, such as enhanced mechanical qualities, improved heat stability, and improved processing. It has several different uses, including in the construction, packaging, automotive, and electronics industries. As a result, it is a crucial tool for enhancing the functionality and performance of a variety of materials.