It is impossible to achieve energy saving, pollution reduction, and sustainable development without the lightweight nature of new energy vehicles. Plastics and composite materials deserve material firms and new energy vehicle manufacturers devoting more money in thorough study because they are lightweight materials with good performance. The excessive mass of the vehicle has turned into one of the barriers limiting its development, particularly at the current stage of the new energy vehicles’ rapid development. Vehicles powered by new energy must be developed quickly and efficiently. New energy vehicle development is becoming more and more significant as a result of the ongoing advancements in plastic and composite material technology.

The new energy automotive sector strives for lightweight, and polymers might be quite important in this regard.

The demand for modified plastics in the automobile industry will rise quickly as a result of the advancement of plastic modification processing technologies and the growth of the national economy.

Along with the rising demand, plastic part requirements for various parts are also rising at the same time. All of them are encouraging the development of modified plastics in a higher-end and more varied direction, from the weather resistance of the outside to the low VOC of the interior to the high temperature resistance of the engine.

The only way to differentiate output is by ongoing innovation, R&D, and The cornerstone of the vehicle industry and the basis for achieving the best outcome are characteristic modified plastics, which provide the greatest stability of supply and production in the post-epidemic age.

Low density and excellent performance are two advantages of modified plastics, which have seen an increase in demand in recent years from the auto sector. Consider modified PP, which accounts for the majority of applications in automotive plastics. When compared to engineering plastics, its benefits include simple processing, simple recycling, high cost performance, excellent chemical corrosion resistance, and good mechanical properties. These attributes can help manufacturers ensure cost and energy savings while enhancing product quality and driving safety.

PP is one of the lightest forms of plastics at the moment and has a low density for automotive plastics. Due to its low density, polypropylene (PP) offers crucial techniques and concepts for developing lightweight automotive solutions.

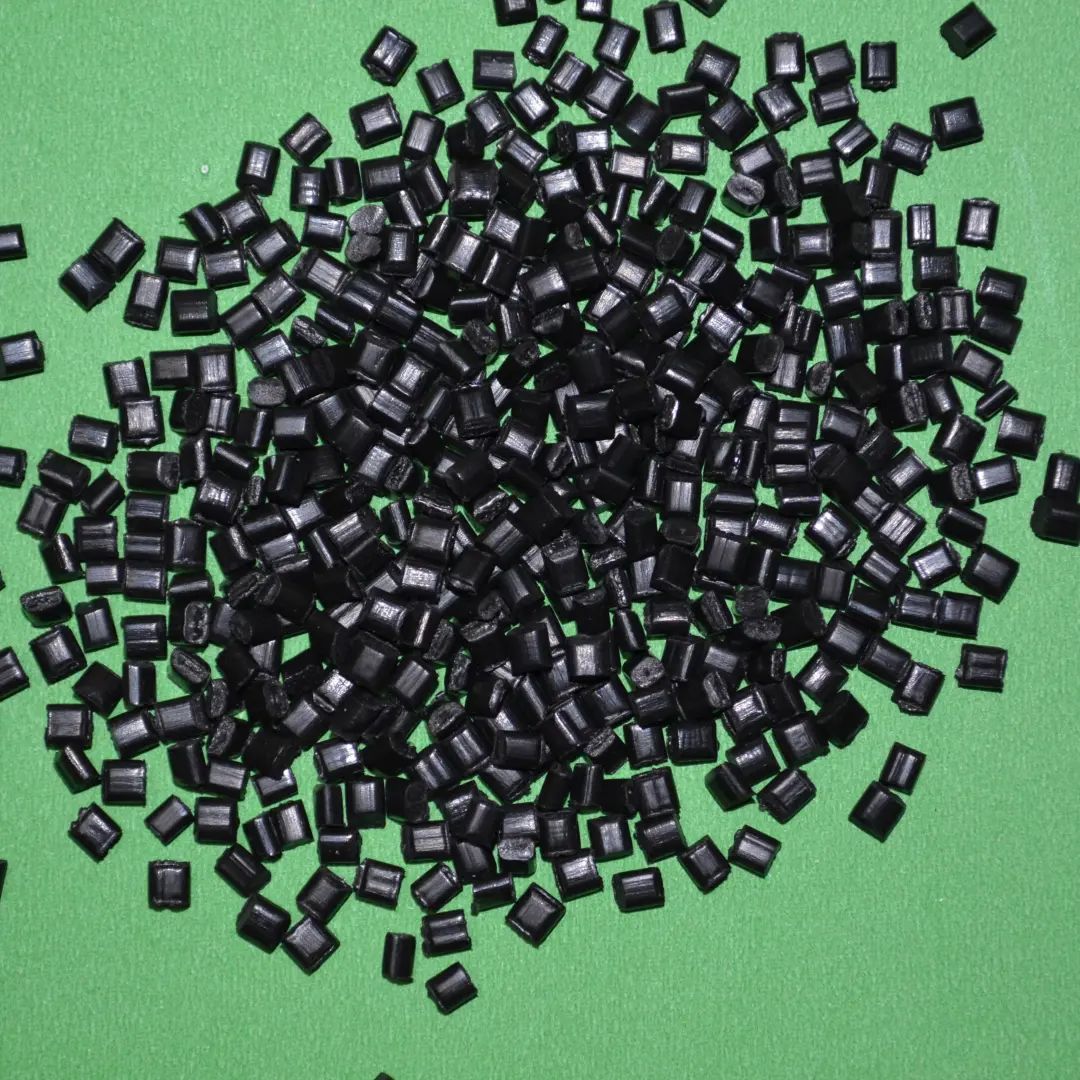

The term ” modified PP” refers to the use of PP as the basic material and the addition of auxiliary components by filling, blending, strengthening, and other means to enhance PP’s performance in terms of, for example, strength, impact resistance, electrical conductivity, and flame retardancy. As a result, PP modified polymers are crucial to the process of making automobiles lighter. In addition, PP is more readily recyclable than engineering plastics, and there are well-established recycling industry chains both domestically and internationally.

Shanghai Preet, a renowned manufacturer of modified plastics in China, specialises in the R&D and production of modified plastic components for automobiles. Modified PP materials make up the majority of its product line. It is evident that PP modified plastic is widely used in the automotive industry. The new generation of manufacturing, symbolised by new energy vehicles, has emerged as the unavoidable course of future automotive development in the period of rapid new energy development. This material is a “seed player” in the world of automotive materials thanks to its various benefits.Naturally, the modified plastics used for the battery pack shell are given great importance. They must satisfy high mechanical performance standards like stiffness and strength as well as functional standards like flame retardancy.

• High-toughness V0-class flame-retardant polypropylene composite material for battery casings: This composite material has good mechanical qualities as well as V0-class flame-retardant capabilities. It can be used to make battery casings. The process for making the high-toughness V0 grade PP composite material for flame-resistant battery shells is also straightforward, simple to produce industrially, and has a wide range of potential applications.

• Conductive, antibacterial, long glass fibre reinforced polypropylene composite material: It can be used for battery pack modules and interiors of new energy vehicles. Together with other composite materials like continuous glass fibre and polypropylene, the composite material can considerably increase the mechanical properties of the material in addition to achieving optimal conductivity and antibacterial effects.

• Conductive, antibacterial, long glass fibre reinforced polypropylene composite material: It can be used for battery pack modules and interiors of new energy vehicles. Together with other composite materials like continuous glass fibre and polypropylene, the composite material can considerably increase the mechanical properties of the material in addition to achieving optimal conductivity and antibacterial effects.

• By using PP as the base resin and adding halogen-free intumescent flame retardant, the battery pack moulding cover’s flame retardancy can be significantly improved, helping to prevent spontaneous combustion brought on by the battery pack working for too long. The device uses upper and lower double channels to chill the moulded goods in the cavity simultaneously, significantly lowering the rate of product moulding rejects.

stacking charges

The market for charging piles will undoubtedly grow as a result of new energy vehicles, and there is also plenty of room for the use of modified polymers in charging piles.

The modified PP shell for new energy vehicle charging piles can not only help reduce the vibration caused by moving, but also enhance its anti-seismic performance, increase the range of application for new energy vehicle charging piles, and better maintain the stability of new energy vehicles. The new energy vehicle charging pile’s stability can be improved and the damage caused by impact to the pile can be effectively reduced by the charging pile’s stability during charging.