styrene-ethylene-butadiene-styrene block copolymer (SEBS), ethylene-vinyl acetate copolymer (EVA), ethylene-octene copolymer (POE), and The effect of its maleic anhydride graft on the toughening performance of nylon 6 (PA6) at different ratios are three elastomers with different structures that are examined in this paper. Through microscopic morphological observation and theoretical analysis, the contributing elements were compared.

Background statement

The thermoplastic resins with repeating amide groups—(NHCO)—on the main chain of the molecule are collectively referred to as nylon. It is a semi-crystalline polymer with outstanding qualities including high strength, self-lubrication, wear resistance, and heat resistance. This engineering plastic is a significant one. Due to its benefits of high mechanical strength, great wear resistance, and ease of processing and molding, nylon 6 (PA6) has been utilized extensively in various industries including electronics and electrical, the car industry, the equipment business, etc. However, PA6’s industrial applicability is constrained due to its drawbacks, including severe hygroscopicity, low dry and low temperature impact strength, and weak notch toughness.As a result, both academics and industry have expressed a great deal of interest in the composite modification of nylon, with elastomer modification serving as one of the primary methods for increasing nylon’s impact strength.In order to increase the blend’s impact strength technically, elastomer modification and toughening involves melting and combining a small amount of elastomer and rigid nylon matrix to create a microstructure morphology with nylon matrix as the continuous phase and elastomer particles as the dispersed phase.The blend’s impact strength a method of technological improvement. The underlying idea is that while the larger particles can control the expansion of crazes, even the shear bands that result can stop crazes and stop them from turning into cracks, the elastomer particles as the dispersed phase can cause a large number of crazes and shear bands in the plastic matrix under the action of external force. The material’s impact strength has greatly increased on a macroscopic level.

The enhancement of nylon 6’s toughness will vary depending on the structure, physical characteristics, and wettability of the various types of elastomers. The primary focus of this article is on three commonly used elastomers, specifically the styrene-ethylene-butadiene-styrene block copolymer (SEBS), the ethylene-vinyl acetate copolymer (EVA), the ethylene-octene copolymer (POE), and its maleic anhydride graft on nylon 6 (PA6) toughening performance under various conditions.

Experimental part

1.Equipment and supplies for experimentation

Model THE-35, Nanjing Ouli Extrusion Machinery Co., Ltd. co-rotating twin-screw extruder. Pendulum impact testing device: Meister Industries ZBC1251-B model. SEM: scanning electron microscope, Hitachi, Japan, model S-4800.

SEBS: G1643M, Kraton; EVA: E280PV, Hanwha Total Petrochemical; POE, Engage 8150, Dow Chemical; PA6: 3280H, Baling Petrochemical. Tianjin Kemiou Chemical Reagent Co., Ltd. manufactures maleic anhydride. AkzoNobel’s TRIGONOX 101 brand is the initiator.

2. Making a modified maleic anhydride elastomer

Weigh a certain amount of maleic anhydride, melt it into a liquid by heating it fully, and then filter out the insoluble material. A twin-screw extruder is used to extrude and granulate the mixture into the appropriate maleic anhydride after adding the elastomer particles, liquid maleic anhydride, and initiator in a certain weight ratio to a high-speed mixer. Elastomer grafted with anhydride. The extruder’s temperature is kept between 180°C and 220°C, and its rotational speed is 300 rpm.

3. Making hardened composite nylon

Weigh a predetermined quantity of nylon 6 resin and elastomer particles, add them to a high-speed mixer in accordance with a predetermined weight ratio, and blend them uniformly for 3 to 5 minutes. Next, add the blended material to a twin-screw extruder to be extruded and ground into the corresponding toughening nylon pellets. The extruder’s temperature is kept between 240 and 260 °C, and its rotational speed is 300 rpm.

4. Composite toughened nylon’s attributes

Impact magnitude

At 245 °C, injection molding was used to create notched splines from the equivalent toughened nylon pellets from above. The splines had the following measurements: 80 10 4 mm for length, breadth, and thickness; 2 mm for notch height; and 1.5 mm for notch depth. To assess the toughness, the notched Izod impact strength was put to the test using the ISO 180 standard procedure.

Small-scale morphology

In order to eliminate the dispersed phase of the elastomer, the aforementioned composite nylon sample was brittle fractured in liquid nitrogen and the cross-section was etched with hot xylene. It was vacuum-plated with platinum once it had dried, and a 15 KV Hitachi S-4800 field emission scanning electron microscope was employed. The samples’ morphology was examined while the voltage increased.

Results and analysis

1. The influence of various elastomer kinds and their ratios on the impact resistance of PA6

All three elastomers—SEBS, EVA, and POE—can be utilized to effectively toughen PA6, and the latter two have a superior blending ratio. If the elastomer content is too high, PA6’s tensile strength and bending strength will be significantly reduced, and the mechanical properties will be impacted. If the elastomer content is too low, PA6’s toughness will not be significantly improved, making it unable to meet the application requirements. The matrix resin cannot adapt to the current production method due to its excessive viscosity.

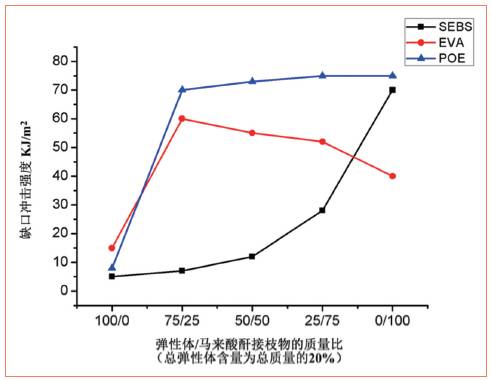

Therefore, the ratio of the elastomer and its corresponding maleic anhydride graft is adjusted, the fixed elastomer is added in an amount equal to 20% of the total mass of the modified plastic, and the improvement effects of the three elastomers on the impact strength of PA6 at room temperature are contrasted. Figure 1 displays the outcomes.

Effects of Different Types of Elastomers and Their Ratio of Maleic Anhydride Grafts on the Impact Strength of PA6

Figure 1 demonstrates that the impact strength of the resulting composite nylon is poor if just elastomer particles are introduced. This is due to the fact that the three elastomers under consideration are all non-polar materials, whereas PA6 is polar, and the two cannot be combined and are incompatible. As a result, even if the elastomer is present in amounts as high as 20%, it cannot be disseminated evenly in the matrix material. No toughening effect may be played. Because pure EVA has the strongest polarity of the three and has one of the best compatibilities with nylon, its toughening effect is marginally superior.

The impact strength of the composite nylon tends to rise as the matching maleic anhydride graft increases because PA6 and the maleic anhydride modified elastomer are much more compatible. When the ratio of elastomer to maleic anhydride graft is 75/25, POE has the best toughening effect among them and has a high impact strength. However, the toughening effect becomes less noticeable when the maleic anhydride graft ratio is increased. enhanced. The EVA elastomer, however, had a behavior of rising initially before sinking. This could be because the maleic anhydride grafted EVA has a high degree of crystallinity and that causes the composite material to become more fragile when the dose is increased.

Because the polystyrene “hard” chain segment in its chain segment has a significant steric barrier and has poor compatibility with the matrix when it is not changed, SEBS can only improve toughening effect by adding pure maleic anhydride grafts. Winding is hard to distribute, which has a bigger detrimental effect.

2. Composite toughened nylon microstructure

Elastomer particles make up the dispersed phase and PA6 is the continuous matrix resin in the composite toughened nylon material. We carried out solvent etching on the composite material to more clearly demonstrate the region of the matrix where the dispersed phase particles are placed.

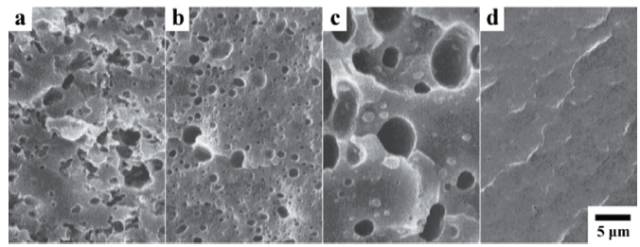

The elastomer particles may be selectively dissolved in xylene, after which the electron microscope can be used to view the continuous phase’s hole structure and the corresponding dispersed phase, as shown in Figure 2.

Picture the composite nylon section in Fig. 2 after it has been etched, with additions of 20% SEBS, 20% maleic anhydride grafted SEBS, 20% POE, and 20% maleic anhydride grafted POE.

When pure SEBS is added to PA6, the resulting microstructure (Fig. 2a) shows irregular holes, suggesting that the distribution of SEBS in the matrix is made up of irregular particles, while the SEBS that has been changed by maleic anhydride is also present in the matrix. They are uniformly distributed, tiny, spherical particles (Fig. 2b). The pure POE elastomer in Figure 2c

POE is spherically distributed in the matrix, although it is much larger and more unevenly distributed than SEBS. After modification, the elastomer particles are equally distributed throughout the matrix and very tiny in size. Even after etching, no evident cavity structure can be seen (Fig. 2d).

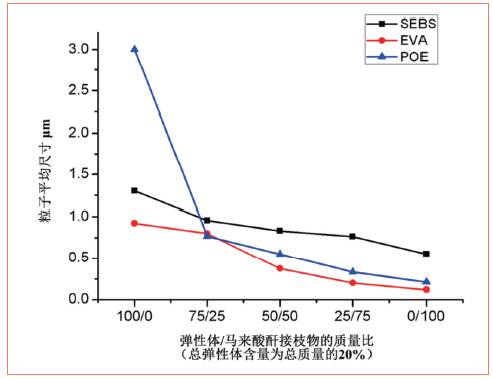

Figure 3 shows the impact of various elastomer types and the ratio of maleic anhydride grafts on the size of the dispersed phase particles.

Additionally, at various elastomer/maleic anhydride graft ratios, we measured the average particle size of the dispersed phase of the three elastomers, and the findings are displayed in Figure 3.

The balance between kinetic and thermodynamic forces during the blending process is shown in the size of the dispersed phase. The particle size of the dispersed phase is significantly bigger than that of the other two elastomers when there is just pure POE elastomer present. On the one hand, the dispersal process is impeded since the unaltered POE has poor compatibility with the matrix. The polar maleic anhydride segment appears to encourage the elastomer’s penetration into the PA6 matrix, resulting in a more uniform dispersion, as seen by the steady reduction in particle size of the dispersed phase with the addition of maleic anhydride-modified elastomer.

The size of the dispersed phase is not the only component impacting the impact strength of the composite material, it should be noted at this point. The dispersed phase material’s physical characteristics, size distribution, and secondary structure will all affect the impact strength. The ideal toughening effect for a given material can be attained in a suitable particle size range. When the dispersed phase size is between 0.5 and 0.7 m for these three elastomers, the toughening performance is rather excellent.

In summary

On the impact strength of PA6 toughened composite products, the effects of SEBS, EVA, POE, and their matching maleic anhydride grafts were compared. Only pure elastomers are utilized for toughening, according to experiments, and EVA has the best toughening effect of the three. The impact strength steadily rises with the addition of maleic anhydride grafted elastomers, and the overall toughening effect is the best of the three.

The impact strength of the composite result depends on the size of the elastomer’s dispersed phase in the PA6 matrix. The unaltered elastomer has a larger scattered phase; adding grafts of maleic anhydride causes the dispersion phase to shrink.

The three elastomers’ dispersed phase sizes, which vary from 0.5 to 0.7 m, have a good toughening impact on PA6.