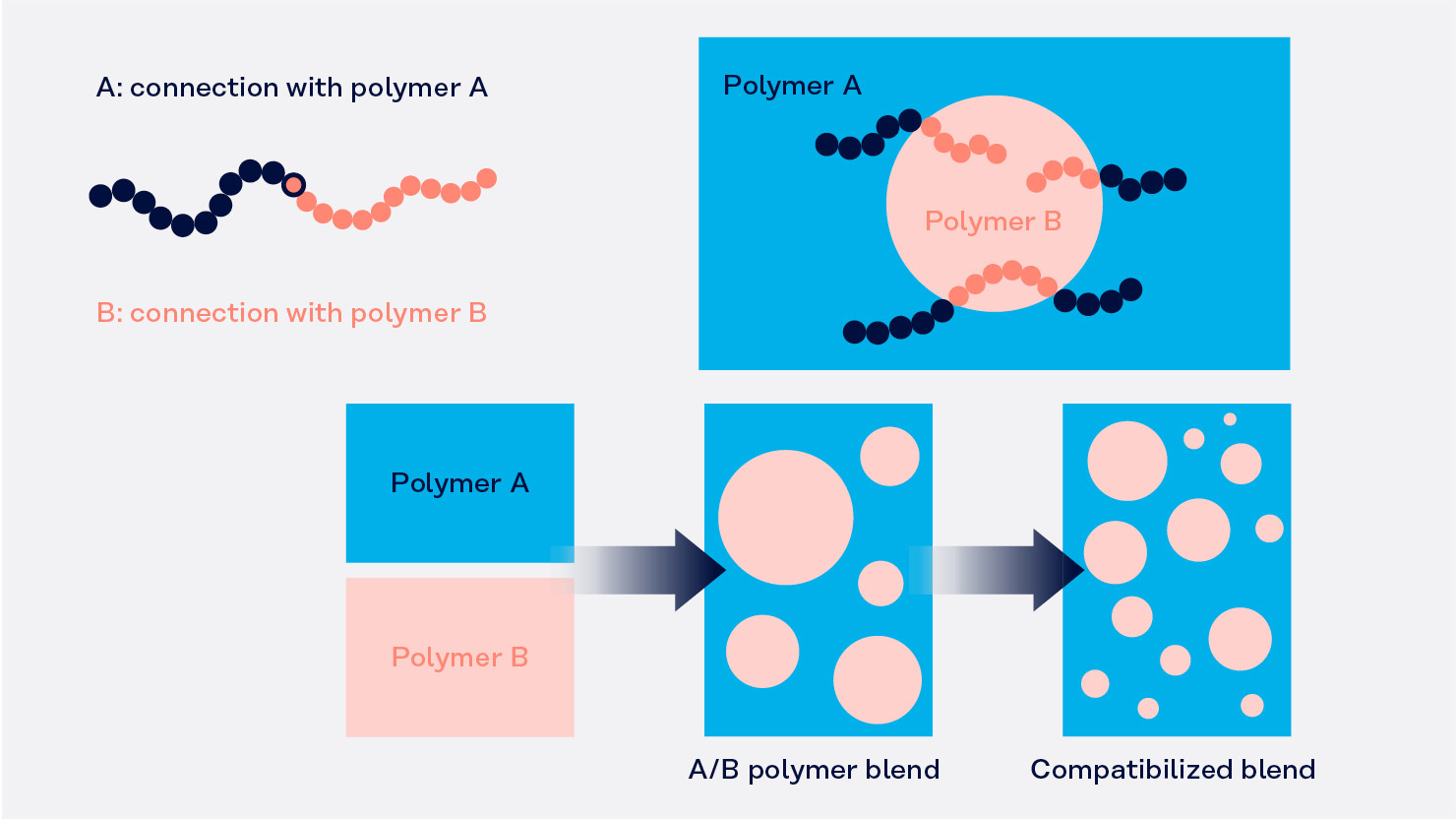

A new class of functional plastic additive is known as a compatibilizer. It is also known as a polymer coupling agent or a macromolecular organic polymer compatibilizer. The purpose of the compatibilizer is to address some polymers’ poor blending compatibility. Its purpose is to lessen the tension between the surfaces. To increase the compatibility of the two polymers, so that the bonding force between them increases and a stable blend structure is formed, a third component was added. This increased the thickness of the interfacial layer, prevented the dispersed phase from coagulating, and stabilized the formed phase structure.

The goal of polymer blending modification is to increase the compatibility of various polymers, and this may be achieved by adding the right quantity of a compatibilizer. Fix the issues with delamination, surface peeling, and poor mix product strength during injection molding, extrusion, and other processes.

What distinguishes the maleic anhydride graft compatibilizer from the coupling agent? Which one is better for filling polypropylene (PP)?

By doing this, the performance of the composite material may be increased as well as the bonding strength between the resin and the reinforcing material. Additionally, it can enhance the condition of the interface, inhibit the entry of other media, and boost the product’s performance in terms of aging resistance, stress resistance, and electrical insulation. The coupling agent may be categorized into four groups based on its chemical make-up and structure: organic chromium complexes, silanes, titanates, and aluminate compounds.

Compatibilizer, sometimes referred to as compatibilizer, is a phrase used to describe the use of intermolecular interaction to encourage the fusion of two incompatible polymers and produce a stable additive mixture.It is utilized to modify plastic. You can get blended materials with good qualities. Presently, maleic anhydride is often grafted onto improved compatibilizers. Maleic anhydride monomer has more polarity and a superior compatibilizing impact when compared to other monomers. By adding strong polar reactive groups, the maleic anhydride graft compatibilizer increases the material’s polarity and reactivity. It is a polymer interface coupling agent, compatibilizer, and dispersion accelerator that is primarily used in filling, toughening, glass fiber reinforcement, metal bonding, alloy compatibility, etc. It can significantly increase the compatibility of composite materials and the dispersion of fillers, improving the mechanical strength of composite materials.

A maleic anhydride-grafted compatibilizer can enhance the compatibility of organic and inorganic fillers, boost product tensile and impact strength, achieve high filling, use less resin, promote processing fluidity, and smooth out rough surfaces.

The interfacial connection between the polymer and the inorganic filler is strengthened by the coupling agent. If the PP simply contains glass fiber reinforcement, there is no need to include a compatibilizer unless there are additional polymer components, such as tougheners like elastomers. The compatibilizer is often related to two distinct polymers. It is better to treat the glass fiber with a coupling agent before adding it to the matrix if it must be utilized simultaneously.

What makes PE wood-plastic composites the most compatible?

In wood-plastic composites, there are primarily two types of compatibilizers: binary or terpolymers of polar monomers (like MAH, acrylic acid, and acrylate) and non-polar olefinic monomers (like ethylene, propylene, and styrene), such as ethylene-vinyl acetate copolymer, ethylene-acrylic acid Ester copolymer, etc.;

Graft copolymers, such as MAH, acrylic acid, butyl acrylate, amine acrylate, methyl methacrylate (MMA), methacrylic acid Glycidyl ester (GMA), etc., are grafted with polar monomers in thermoplastic elastomers or polyolefins. The most popular graft monomer is MAH, and the most popular graft copolymers are PP-g-MAH,PE-g-MAH, maleic anhydride-grafted EPDM, and SBS-g-MAH.

The majority of these compatibilizers contain polar groups, including carboxyl or ester groups, which can establish hydrogen bonds or conduct esterification processes with polar groups in plant fibers, lowering their polarity and hygroscopicity. A non-polar segment with strong compatibility with the polymer is also included in the compatibilizer. This segment serves as a “bridge” to efficiently link the plant fiber and polymer interface, enhancing the interfacial bonding performance of the two. The suggested compatibilizers are Bp-4, POE, maleic anhydride grafted polymer, and ethylene-octene copolymer.