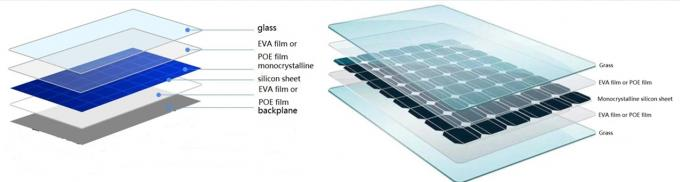

The development of battery technology has a bigger influence on the choice of supporting auxiliary materials, notably the packaging film, in the context of the rapid proliferation of new high-efficiency batteries.

Although the adhesive film makes up only about 5% of the photovoltaic industry chain, its quality is crucial because the packaging process for solar cells is irreversible and the operating life of components is typically required to be more than 25 years. As a result, once the light transmittance of the adhesive film decreases during operation, photodegradation, corrosion, delamination, and other failure problems will cause solar cells to be scrapped, rendering the module unusable.

Currently, EVA film, EPE film, and POE film make up the majority of the encapsulation film used for solar modules. then, how do I decide?

01 Benefits of EVA

Good adhesion: Due to the outstanding adhesive qualities of EVA, solar cells and backsheets may be securely joined to create a dependable module structure.

High light transmittance: The solar cells’ ability to generate electricity is increased by EVA’s high light transmittance, which can transfer light to them to the greatest degree.

EVA has strong weather resistance to UV radiation, humidity, and temperature variations, which helps prevent component deterioration due to external causes and extend service life.

Electrical insulation: EVA is an electrical insulating substance that can isolate the current flowing between the solar cell’s back sheet and the cell itself, prevent the cell from shorting out, and enhance electrical safety.

Cost-effective: EVA is utilized extensively in the solar sector thanks to its affordable price when compared to other high-performance adhesives.

02 Drawbacks of EVA

Poor thermal stability: Under high temperature circumstances, EVA has relatively poor thermal stability, which might lead to issues like aging, deformation, or adhesive layer separation.

EVA may experience damp-heat aging in high-temperature, high-humidity environments, which can impair performance.

Poor gas permeability: EVA has a low gas permeability, which might lead to gas accumulating inside the component and impairing its performance.

03 Benefits of POE

Superior thermal stability: When compared to EVA, POE is more thermally stable at high temperatures and is more resistant to thermal aging.

Strong weather resistance: POE is appropriate for tough climatic circumstances and has strong weather resistance to UV radiation, humidity, and temperature variations.

POE can be utilized as an alternative to or addition to EVA, offering various performance and application choices.

Electrical isolation and protection: POE is a substance that may be used for electrical insulation.

04 Disadvantages of POE

Higher price: The cost of POE is greater than that of EVA, which might raise the price of producing solar modules.

Poor light transmittance: Compared to EVA, POE has poorer light transmittance, which might have an effect on how well solar modules generate electricity.

05 Comparison

Due to the EVA film’s characteristics of continuous acid release, high water absorption, and water vapor transmission, even during normal use there will still be water vapor transmission, light transmittance reduction, acid release, and delamination failure, among other things, which will reduce the power generation of the components. In particular, the acetic acid molecules released by the breakdown of the EVA film will not only cause the metallized grid lines in N-type batteries to corrode much more quickly than those in conventional P-type batteries, but will also cause long-term failure of the new N-type battery components. increased risk of dependability.

In den letzten Jahren wurde außerdem festgestellt, dass die EVA-Folie ein erhebliches Problem mit der potenzialinduzierten Degradation (PID) hat, was zu einer erheblichen Verringerung der Leistung des Kraftwerks führt.

Pure POE film, as opposed to EVA film, ensures the safety and long-term aging resistance of photovoltaic modules in high-temperature and high-humidity environments, allowing the components to be used more effectively for a longer period of time. This is because of its unique anti-PID performance, high resistivity, and low hydrolysis characteristics.

Although the lamination performance of the EVA film and the anti-PID performance of the POE film are taken into consideration by the EPE film, the drawbacks are also readily apparent.

The intermediate layer’s POE thickness control is not consistent, and the POE layer’s additives are easily transferred to the EVA layer. After migration, the rate of POE cross-linking decreases, and during the lamination process, POE in the EPE film is extruded by the EVA on both sides, increasing the danger of delamination and other issues. EPE has not yet made significant advancements in N-type battery technology. extensive empirical validation. What’s more, the potential of EVA to continually release acidity has not been completely eradicated in EPE, casting significant doubt on the long-term dependability of EPE in N-type batteries.EVA is still unable to make direct contact with the battery’s front.

The demand for pure POE-Film will undoubtedly see a significant positive pull as the share of N-type modules in the market continues to rise.