Modification

1. Mixed modification

The mixed reform is to mix nylon 6 with PP, PE, ABS, PET, PC, POM, PPO and other elastic bodies or other materials such as the elastic body or other materials such as Sanyuan Ethiop Rubber. A common method of modification. Through the mixed modification, complement the advantages of nylon 6 with other materials, which can effectively improve the mechanical properties and size stability of Nylon 6, and reduce water absorption.

2. Filling enhancement modification

Filling enhancement modification is a common method for physical modification of PA6. It refers to the glass fiber, carbon fiber, crystal beard, siliconite, calcium carbonate, talcum powder, rare earth, cloud mother, silicon dioxide, silicon dioxide, silicon, silicon, silicon, silicon, silicon, and silicon. Wait for the modification of PA6 to significantly improve the mechanical properties, flame retardant performance, thermal conductivity, and size stability of the material.

3. Co -agglomeration and modification

The PA6 cluster modification mainly includes a convergent between the unilateral and amide monomers, the co -concentration between the amide and non -amide monomers. The molecular chain can be transformed through the co -concentration. On the PA6 molecular chain, improve the performance of all aspects, and prepare a new product that meets specific requirements.

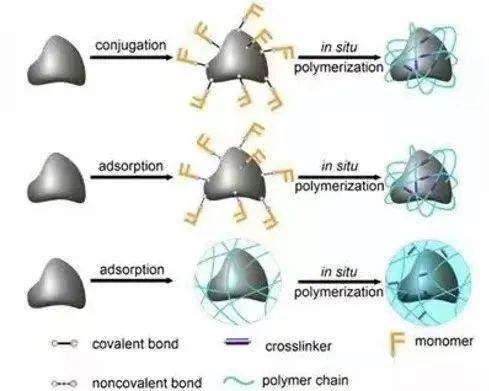

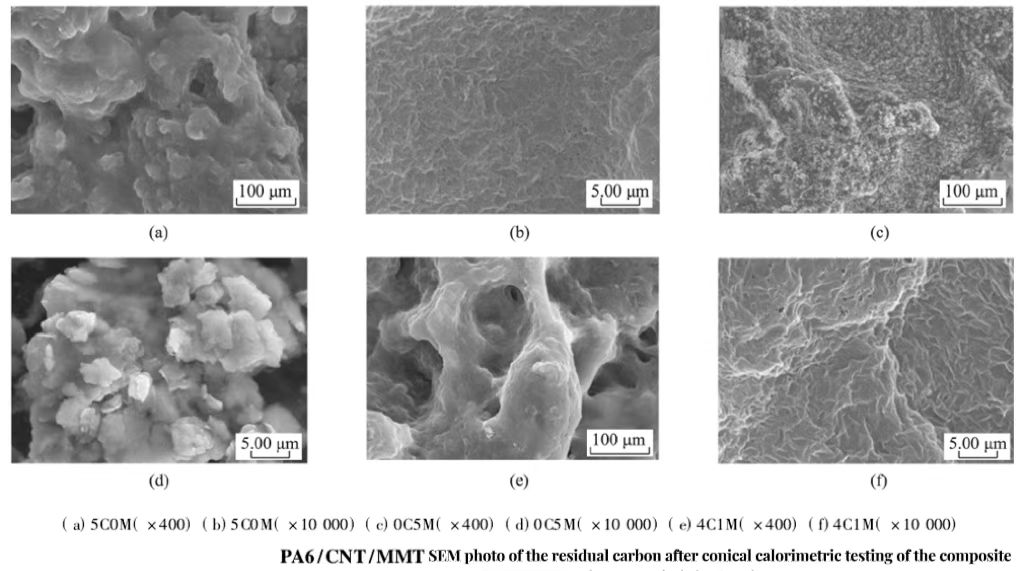

4. Nano -compound modification

At present, nanomaterials are mainly used to modify PA6 include carbon fiber, carbon nanotubes, graphene, masked soil, and inorganic nanoparticles. Utilizing unique advantages such as nanomaterials larger and good, good mechanical performance, good conductivity, and thermal conductivity performance, PA6 and nanomaterials are compounded by melting and co -agglomeration through melting, so as to enhance the performance of all aspects of PA6.

Anwendungen

1. Fiber -grade slices

It can be used for spinning people with silk, underwear, socks, shirts, etc.; For the spinning industry silk, as tire curtain cable, canvas wire, parachute, insulation material, fishing net silk, seat belt, etc.

2. Engineering plastic section

It can be used to produce gears, shells, hoses, oil -resistant containers, cable shestages, and textile industry equipment parts of precision machines.

3. Plug -level slices

Can be used for packaging industry, such as food packaging, medical packaging, etc.

4. Nylon composite material

Including anti -impact nylon, enhanced high temperature nylon, etc., used to make special needs, such as enhanced high temperature -resistant nylon can be used to create impact drills and grass -cut machines.

5. Car products

At present, there are many types of car products in PA6, such as radiator box, heater box, radiator blades, steering column hoods, taillhills, timing gear hoods, fan blades, various gears, radiator water rooms, air filter shells, inlet, inlet Air ducts, control switches, air intake ducts, vacuum connecting pipes, airbags, electrical instrument housings, water scrapingrs, pump leaf wheels, bearing, band, valve seats, door handles, wheel masks, etc. In short , Electric components, body components and airbags.