The new energy vehicle industry is an important direction for green development in the transportation field under the goal of “double carbon”. Accelerating the industrialization of new energy vehicles is not only conducive to technological progress and energy conservation and emission reduction, but also promotes the sustainable development of China’s auto industry. In addition, what new actions have been taken by the big players in materials recently.

Modified plastic materials as an important part of advanced polymer materials, has been widely used in various fields such as home appliances, automobiles, electronics and electrical. For the charging facilities industry, some of the leading enterprises in the modified plastics industry have conducted sufficient research on the application of polymer materials in the charging pile, and are capable of providing overall solutions of polymer materials for the charging pile.

Charging pile shell

As the external protection parts of the charging pile, the charging pile shell not only needs to meet the protection requirements of possible collision during transportation, installation and use, but also must be suitable for the complex working conditions, and the materials used need to have certain mechanical strength, electrical insulation and flame retardancy requirements, as well as excellent weather resistance, low temperature impact performance, corrosion resistance and processing performance.

It is recommended to use halogen-free flame retardant PC materials or halogen-free flame retardant PC alloy materials, such as halogen-free flame retardant PC/ABS, PC/ASA, PC/PBT materials, etc., including the combination of the use of spray-free technology, which can be made into different appearance colors to meet the individual needs of different use occasions.

Charging gun and connection system

Specifically includes the charging gun shell and connection head. In addition to flame retardant, electrical insulation performance and weather resistance, the shell of the charging gun should have good rigidity and toughness to avoid damage caused by dropping and rolling over by vehicles, while taking into account a good appearance. Halogen-free flame retardant and weather resistant PC and its alloy materials are recommended.

Charging connectors, including sockets and plugs, directly connected to the wire, need excellent electrical insulation, flame resistance, heat resistance, and to meet the long-term plug life requirements, the material needs excellent mechanical properties. Recommend the use of halogen-free flame retardant reinforced nylon material.

Internal control system components

Internal control system components mainly include power supply module, contactor, circuit breaker, cooling fan, etc. Referring to the material application of common power system and low-voltage electrical industry, halogen-free flame retardant reinforced PA or PBT materials can be used. The cooling fan is recommended to be made of flame retardant reinforced PBT or PPE material which is widely used in IT industry.

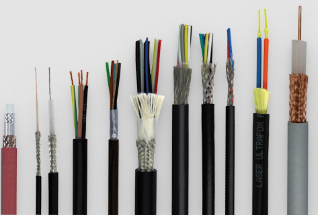

Cable assembly

The cables used in charging piles mainly include power and signal control cables. Detailed regulations are made on the structure, rated voltage, operating temperature, allowable bending radius and durability of charging pile cables. Polymer materials are mainly used in the inner sheath and outer sheath of the cable. The inner sheath can use halogen-free flame retardant TPE, TPU, and the outer sheath can use PVC, halogen-free flame retardant elastomer, etc.

With the continued promotion and application of new energy vehicles, the miniaturization and lightweight of charging facilities will be the future direction of development, some new high-performance modified plastic materials, such as PPS, PPO, PEEK, and other elastomeric materials, are likely to be in the charging facilities for engineering applications, which has a good role in promoting the application of modified plastics in new energy vehicles.